Combined Smart Effector and tool board for delta printers

-

With the release of the new Duet 3 Roto Toolboard I am not sure if a new smart effector is really needed. for me the main advantage of the smart effector was nozzle probing. But with the new Scanning Z-Probe Nozzle probing is already obsolete in my opinion. Of course you woul need to set the probe offset manually with a Scanning Z-Probe. To do this I use either a separate button style probe or I adjust the z height manually with baby stepping and run a simple macro to adjust the probe offset by the baby stepping amount and save the new probe offset in config-override.g.

I would still be interested in buying multiple smart effectors if they support the following points. some of them are obvious but for the sake of completeness...

- Scanning Z-Probe

- onboard accelerometer

- onboard motor driver

- Io input for filament monitor

- VZ style hotend mounting holes for Hotends like the Phaetus Rapido, VZ-Revo or Mellow Goliath Hotends.

- Enough space for direct drive extruders.

And lastly not necessarily a must but it is nice to have options.

- A hotend mosfest that can handle <100 W (Mellow Goliath Hotend)

Since I use CPAP style part cooling and watercooling for the hotend I do not require fanports on the tool board. But I recon This would be a no-go for most users.

-

@MaxGyver for delta printers I strongly recommend a nozzle contact probe. The reason is that it is very hard to prevent the effector from tilting slightly as it moves in X and Y; and with an offset Z probe any varying tilt will cause the relative heights of the nozzle and the probe to vary. Therefore, unless we can make the probe coil concentric with the nozzle, we can't use the scanning probe on a delta.

-

That's a very good point.

I am wondering if the effector tilt can be measured and actively compensated by software...but this is probably another topic...Ball spacing of 70mm between the ball centers should be sufficient for a compact direct extruder. It would need to be raised tough in order to clear the hotend collet. I have also tried fitting other hotends like the Voron-Revo and Pheatus Rapido/Goliath. The Voron-Revo does not work, but the Pheatus Rapido/Goliath might just work. The M3 mounting holes just clear the center hole of the effector, but I recon it will mess with the placement of the strain gauges. The threaded E3D-V6 and E3D-Revo Micro support a large range of hotend combinations. Maybe we should stick with those for the sake of simplicity.

EDIT: and there is also the option to use an adapter like this

-

I'd be interested in an Orbiter V2.0 or Bondtech LGX Lite or Revo Roto version.

-

@MaxGyver those renders were very helpful. could you do one for the Revo Roto as well?

-

@T3P3Tony said in Combined Smart Effector and tool board for delta printers:

@MaxGyver those renders were very helpful. could you do one for the Revo Roto as well?

Of course, I am happy to!

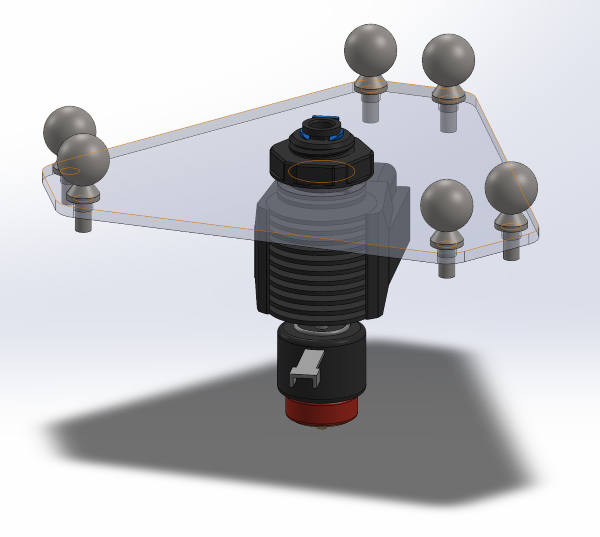

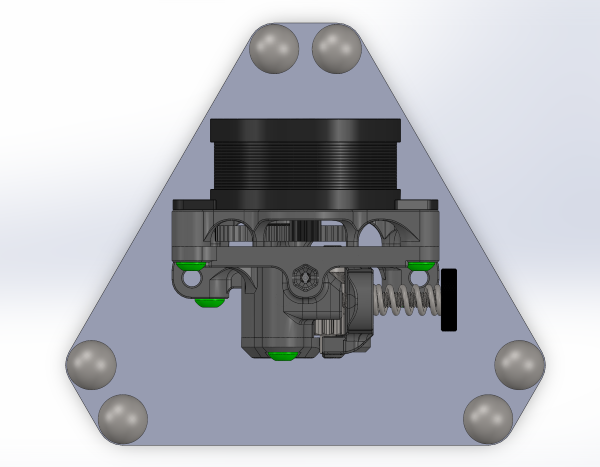

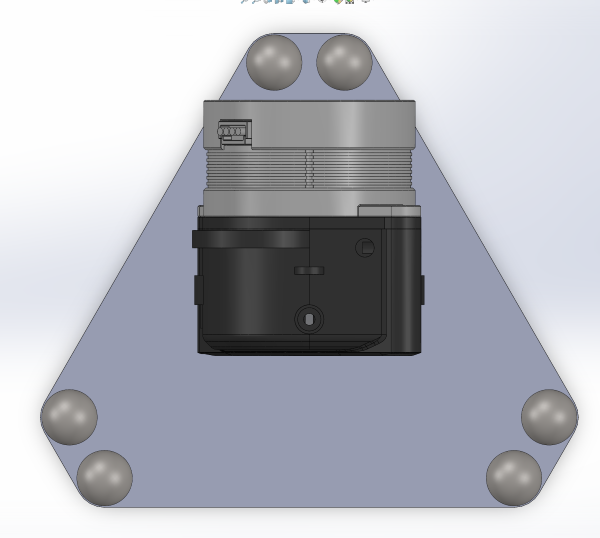

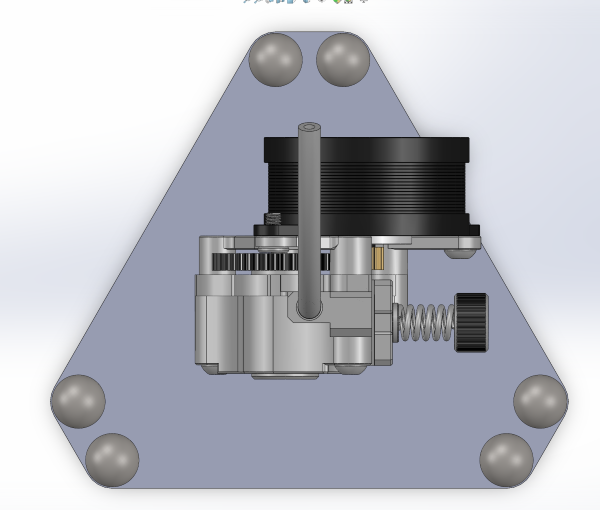

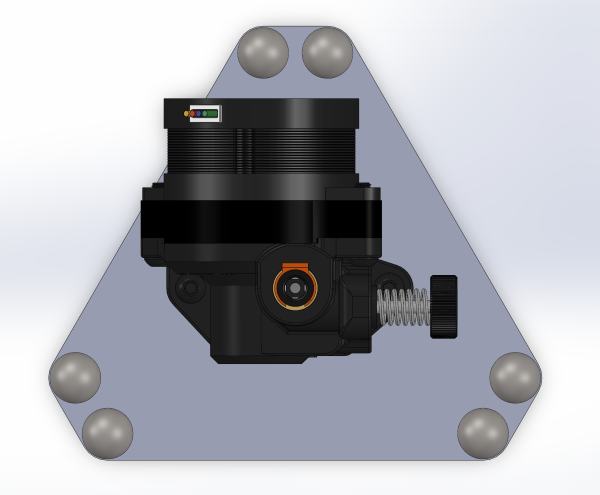

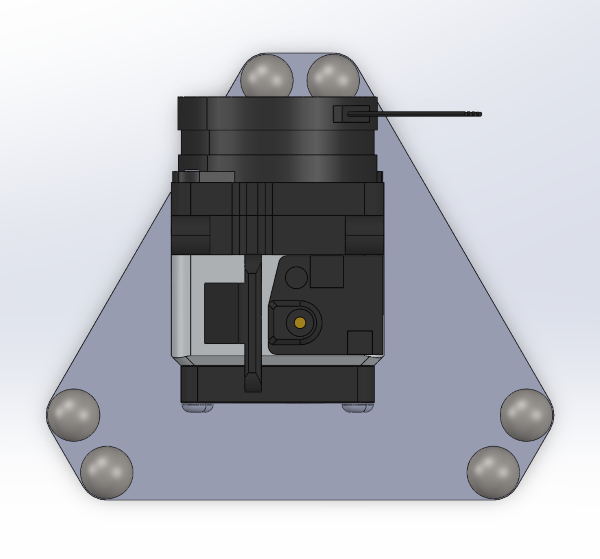

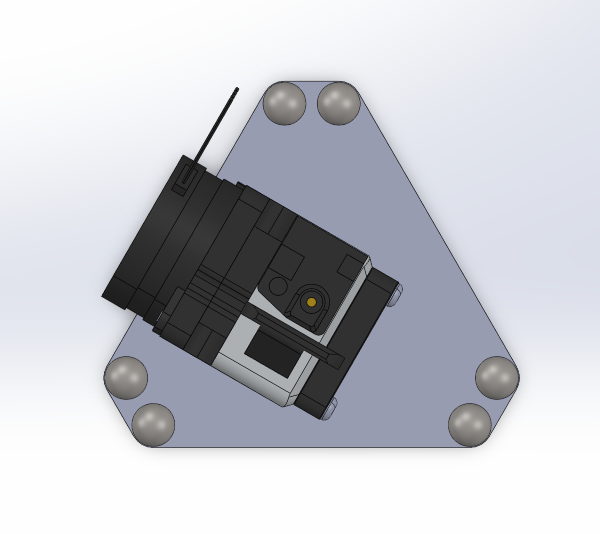

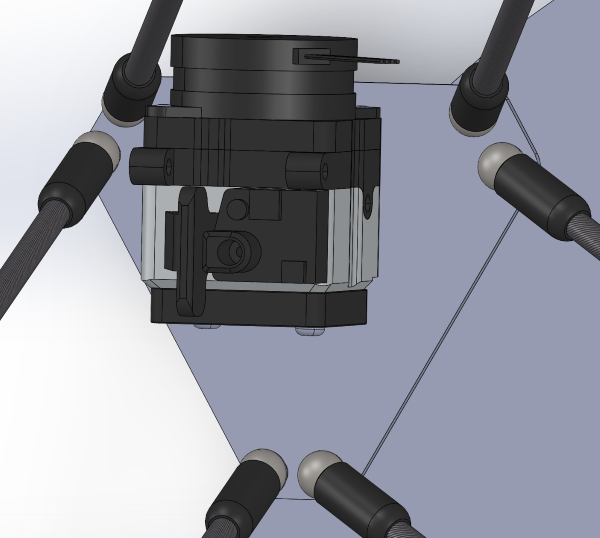

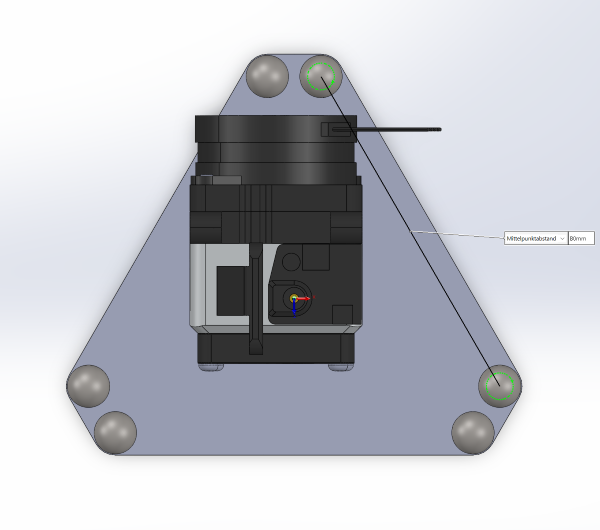

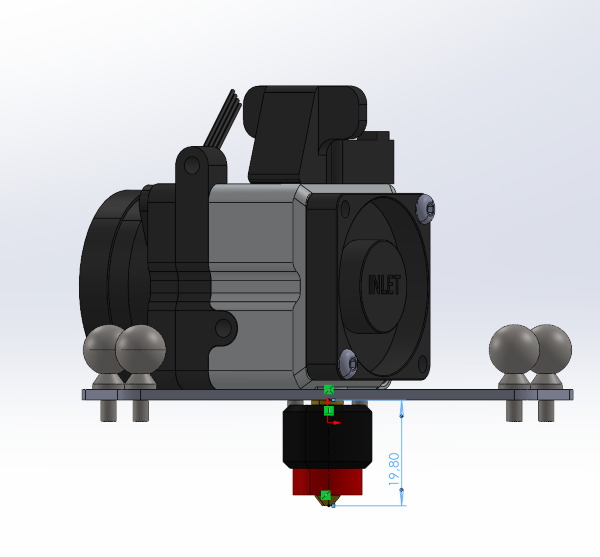

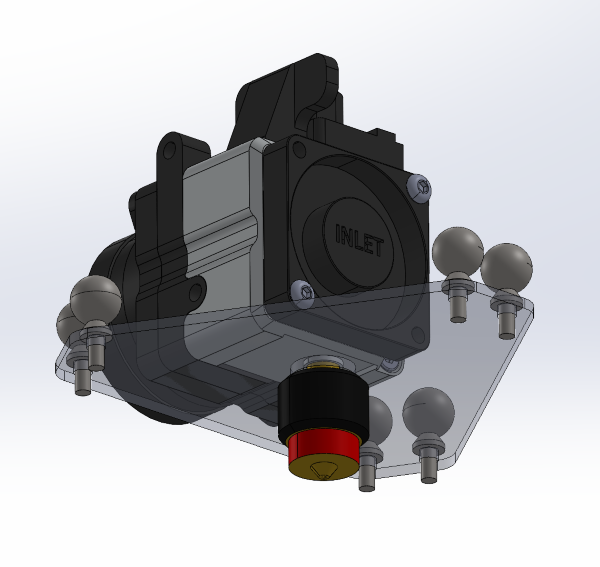

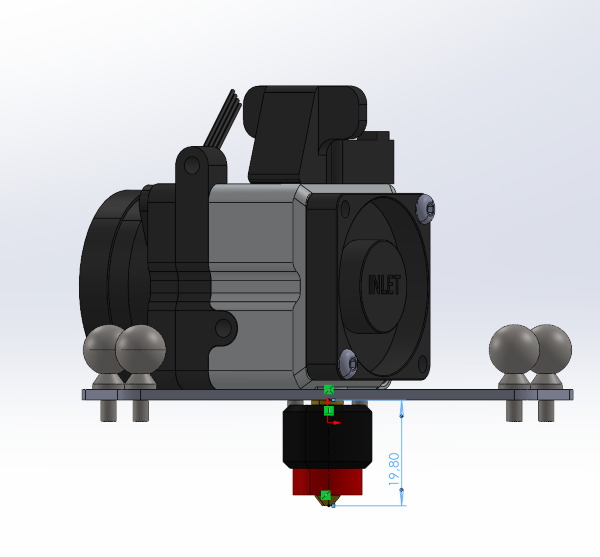

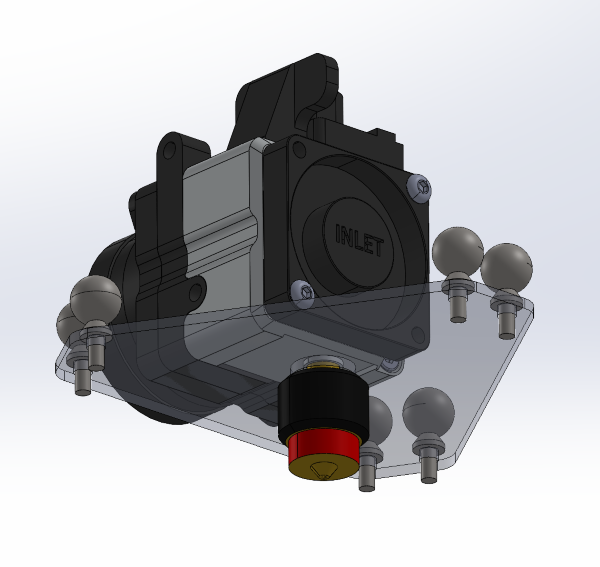

The Revo Roto is a bit longer, so it would have to be rotated by 60°

The setup would be extremely compact.

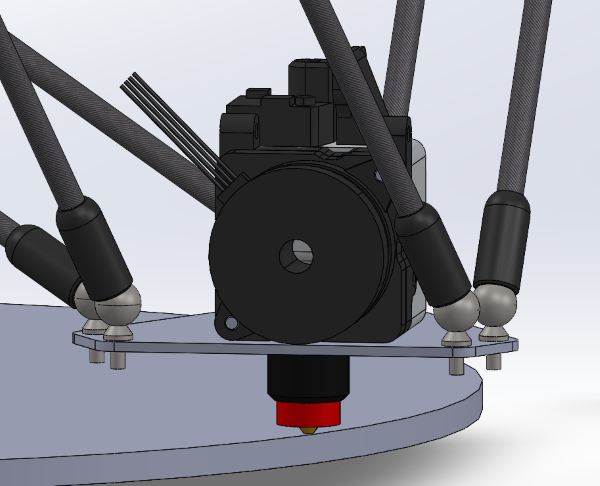

I have designed a Delta Printer a while back and was basically waiting for a CAN-Smart effector to emerge. So I took the chance to ckeck for any collision points between extruder the Arms (360mm Haydn Magball Arms).

And it looks like the Revo Roto will juuuust fit.Unfortunately, there is no way to mount the Revo Roto from below trough the effector plate

-

I would buy an updated effector and new extruder assembly if available.

-

@MaxGyver said in Combined Smart Effector and tool board for delta printers:

@T3P3Tony said in Combined Smart Effector and tool board for delta printers:

@MaxGyver those renders were very helpful. could you do one for the Revo Roto as well?

Of course, I am happy to!

The Revo Roto is a bit longer, so it would have to be rotated by 60°

The setup would be extremely compact.

I have designed a Delta Printer a while back and was basically waiting for a CAN-Smart effector to emerge. So I took the chance to ckeck for any collision points between extruder the Arms (360mm Haydn Magball Arms).

And it looks like the Revo Roto will juuuust fit.Unfortunately, there is no way to mount the Revo Roto from below trough the effector plate

Wouldn't the tight clearance be solved by rising the balls ever so slightly from the PCB? I mean just 1-2mm would have alot of effect, if it don't play very negstively into the kinematics (I have no experience with Deltas).

-

-

@o_lampe there will be electronic components and the headers for fans, heaters, the stepper motor etc however we may be able to provide a clear area to allow this sort of mounting, won't know until we start the design. Each extruder will need a different shape and amount of clear area however we may get a lot of overlap. Same with mounting holes. In the end we may need an interface bracket or brackets for all or some extruder options.

-

@MaxGyver said in Combined Smart Effector and tool board for delta printers:

Unfortunately, there is no way to mount the Revo Roto from below trough the effector plate

A couple of L shaped printed brackets would be needed for sure.

-

@T3P3Tony said in Combined Smart Effector and tool board for delta printers:

In the end we may need an interface bracket or brackets for all or some extruder options.

Right, I thought the same. But in case of a raised Roto it would interfere with the rods?

-

How much would the rod spacing need to be increased to accommodate the Roto without it interfering with the rods, assuming it is mounted on top of the effector as illustrated earlier?

-

I would try at least one

-

@dc42 My observation was, that the roto's big footprint in @MaxGyver 's illustration was directly on the pcb.

It depends on the height of the components how much the roto would have to be raised.

Other DD-extruders like the hextrudort or sherpa mini have a much smaller footprint. I'd suggest to mount them in the same direction as the roto: with the stepper motor between the rods.A dumb question: with the accelerator chip on the effector, would it be possible to compensate tilt during probing? If so, it wouldn't have to be a nozzle touch probe, but could be any other.

The math for tilt compensation would be easy. You have the offset between probe and effector-center and you can read the tilt-changes between first homing and when the effector reaches the given probing coords. -

I would be interested in a variant for the Roto.

-

-

@MaxGyver thanks for that. I wonder if even 80mm would be sufficient, because your diagram suggests that if the extruder is mounted that way then the motor would likely interfere with the rod to the top left ball.

-

@MaxGyver why would it not be rotated to be between the rods?

-

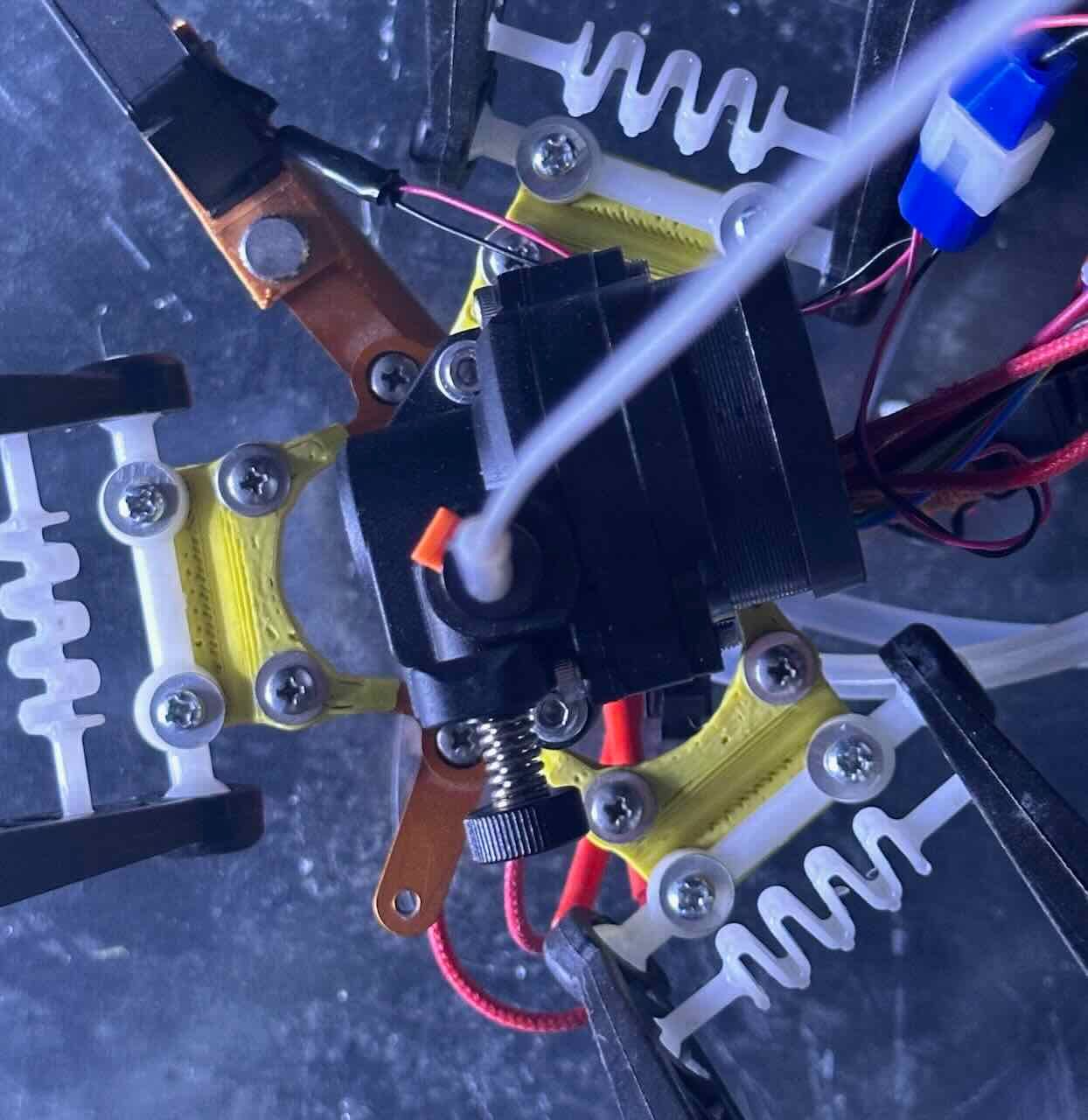

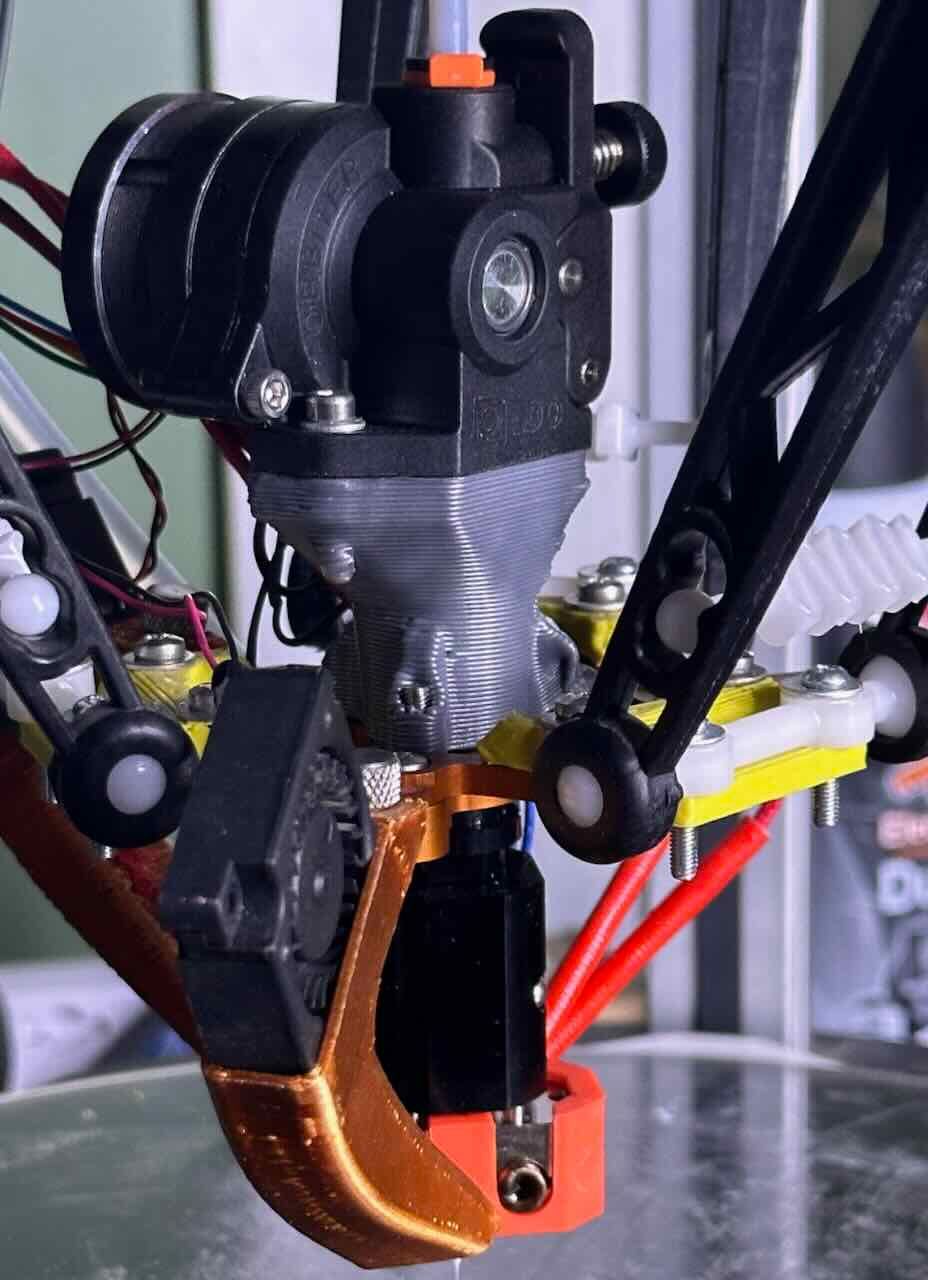

@T3P3Tony This is only semi-on-topic because I have a 713-maker effector plate on my Rostock Max v2, not a Smart Effector.

But I have cobbled together a real-world implementation of an LDO Orbiter V2.0 on that effector. My solution was to rotate (20º) and raise the extruder (25mm) to clear the arms. A short length of bowden tubing within the extender keeps the filament guided between motor and extruder. It turned out that this arrangement cut down on the build envelope more than desired (allowed the motor to hit the arms at the top extreme of the plate) so I moved all of the effector's arm attachment points outward by 13mm (increasing the size of the effector plate).

Raising and rotating the motor might have deleterious effects on momentum/vibration/tilt that outweigh the fact that it allows for a slightly smaller effector plate that still fits the motor between the arms. But it's working for me for the moment.