Fans vs Berd-Air

-

What do mufflers look like?

-

-

Thanks. I missed the link above...

-

Hey All,

I received the pump from @klcjr89 and have played with it a little bit. I plan on doing more extensive testing and a full write up I wanted to give you all some of my initial impressions.

Technical Stuff

- The build quality of the pump seems very good, it feels solid with a good fit and finish

- It absolutely provides enough flow / pressure for the Berd-Air tube(s)

- Connected directly to the PWM fan output of the Duet with no issues

- Due to it being a brushless motor PWM output is a bit more fussy (see notes below)

- Might get hotter than the standard pump (see notes below)

Aesthetic Stuff

- It is much more attractive than the default Berd-Air pump

- It should mount much easier than a Berd-Air pump (see notes below)

- It is more compact than a Berd-Air pump

- Without the mufflers (I do not have a set, but may purchase some) it seems like it might be louder than the standard pump (see notes below)

Other Notes

@klcjr89 mentioned some strange harmonic/auditory issues when running at less than 100% (255 PWM) I found that this only occurs when you are running a PWM frequency that is substantially in the range of human hearing (20hz ~ 20khz). I found that running it above ~17khz resulted in no uncomfortable sounds, which makes sense since I am old enough I probably can't hear above that range anyways .

.That being said 2-wire BLDC motors don't always like being PWM'd. You have to get your PWM frequency set to your liking (I settled on someplace in the 20k range for my initial testing). Depending on the PWM frequency used you will lose a little bit of responsiveness in either the low (<10%) or high (> 90%) range where changing the PWM output will not adjust the pump speed. I don't think this is an issue since with a Berd-Air I rarely need these ranges anyways.

I measured the noise level using a dB meter on my phone and the brushless pump is louder than the standard Berd-Air pump when properly configured; however I don't feel that comparison to the standard pump is not entirely fair at this point. My standard pump is mounted in a way that dramatically reduces the vibration of the pump. For testing this pump it was not mounted at all, I just had it sitting on rag on my desk. I have designed a similar vibration-dampening mount for this pump but I have not yet printed it or tested it; I plan on doing that for the full write-up, as well as posting the mount if people are interested. I also do not yet have the mufflers installed, which would destroy some of the aesthetic benefits of the pump, but would probably reduce the noise level even more.

I didn't run the pump for a full print, so I cannot fully comment on how hot the motor gets at this point, in my initial testing it seemed like it got hotter than my properly configured standard pump.

Thats all for now, I will post a full write up later this week if I have the time to get all the testing I want to do completed!

-M

-

CPAP blowers are not always easy to get or inexpensive if you buy them, so I designed a printable blower that uses a motor from a HDD which most people can get for free. About $3 worth of filament and $5 for a BLDC motor driver via ebay and you can move a lot of air quietly. Printed centrifugal blower/compressor.

I haven't tested it pushing air through a small tube like the Berdair thing. Maybe I'll get a chance in the next couple days.

-

@mrehorstdmd did you find a way to control to control the blower via a PWM input signal, or do you just PWM the input voltage?

I have some motors laying around, contemplating which controller I should use as I have a 24V PSU... -

The driver I'm using has a PWM input pin, but when I tested it on the printer I just PWM'd the power input to the driver. It would probably be better to use the PWM pin.

Of course, they don't provide any specs on the PWM input pin level. I would assume it is a 5V logic level input since there's some 5V parts and a regulator on the board. Maybe compatible with 3V?

-

I was just wondering how your guys brushless pumps are going? I am looking at using either one of them or the berd air pumps. Since it looks like from the age of the posts that they have been running for a while, what are your preferences as to which is better? Have the brushless ones lasted being driven by pwm?

Kind Regards,

Sam -

@mrehorstdmd said in Fans vs Berd-Air:

Printed centrifugal blower/compressor.

Same question here.. any long-term experience updates?

-

i found that

70% of berd-air noise is from pump air flow

30% is from the motorthere are simple solutions for both

Motor noise

use flex mount. for myself i made this one

there are other mounts with even vibration-canceling ones, but require more space. most simple solution (even no print needed) is to hang the motor on the rubber band

AND use 22500 Hz PWM frequency. as a bonus this trick also keeps pump motor cold

Pump airflow noise

use silencers my design makes it silent. very silent. it is a bit tricky to print, but once printed, you will be surprised

-

@klcjr89 The flow rate in the data you posted is in H/L which I read as Hours per Litre. I'm assuming that's a typo and should be Litres/Hour. (Or does it really take >600 hours to shift one Litre of air

).

). -

-

ok, so this is an old post, but it seems to be the most popular on google and useful. Does anyone have any reports on how their berd air systems have held up over time? Have they been excellent or a waste of time? How is their reliability?

Does anyone have any followup data on the brushless aliexpress pump listed? It looks like the choice I am most tempted by at the moment.

-

@Phaedrux said in Fans vs Berd-Air:

@c310 said in Fans vs Berd-Air:

my design

Link is broken.

Hey look the link is working now.

-

@lael I just picked up a brushed system from the makerhive. Much cheaper than the brushless option. I might see if I can make the pump brushless at some point, but for now it's working great. I made my own air mount with some brass tube from Lowe's. Quieter and much easier to work with.

-

@Surgikill I'm curious what size brass tubing you use? I've tried using small hobby brass tubing and even packing the tube with salt powder it would still collapse in on itself in bad ways when i'd try to bend it. I'd much rather use brass than aluminum since the brass would deform without tearing/ breaking as easy as the aluminum, and the akuminum gets more break prone after exlosure to hotend buuut i have not been able to shape it without issues.

-

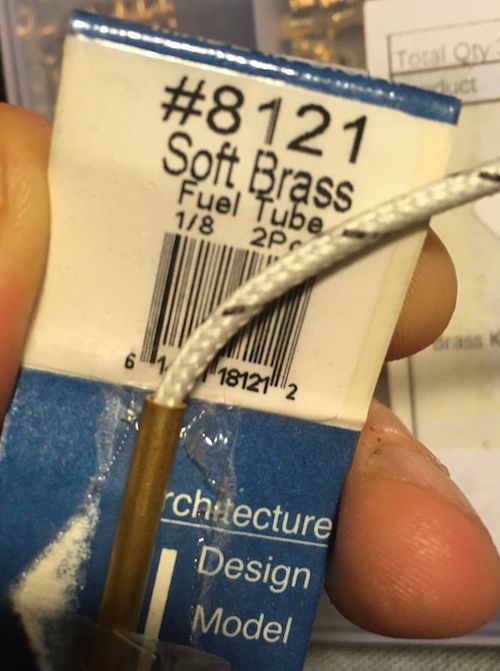

@lord-binky don't use salt, use electric wire. Put it in the tube, bend it and pull the wire. For example, iirc, K&S soft brass (something like 8121) tube is a perfect match for heater cartridge electric wire gauge.

Edit: yes heater cartridge cable perfect fit 8121 K&S soft brass tube

-

@lord-binky said in Fans vs Berd-Air:

@Surgikill I'm curious what size brass tubing you use? I've tried using small hobby brass tubing and even packing the tube with salt powder it would still collapse in on itself in bad ways when i'd try to bend it. I'd much rather use brass than aluminum since the brass would deform without tearing/ breaking as easy as the aluminum, and the akuminum gets more break prone after exlosure to hotend buuut i have not been able to shape it without issues.

Invest in a small tube bender (min version of what plumbers use to bend pipes). Something like this https://www.amazon.co.uk/Tubing-Bender-Degrees-Manual-Bending/dp/B088H1MHWN/ref=sr_1_7?adgrpid=119993429162&dchild=1&gclid=Cj0KCQjwi7yCBhDJARIsAMWFScPk-xcgly9PRIz5mgxBPKlnamYT_OstJqT7pmfj1g5J3HHZ2Dz1Xs8aAohjEALw_wcB&hvadid=501516551233&hvdev=c&hvlocphy=9046150&hvnetw=g&hvqmt=e&hvrand=14776184315352084993&hvtargid=kwd-295847543910&hydadcr=1596_1935511&keywords=small+tube+bender&qid=1615808871&sr=8-7

-

@lord-binky I didn't bend the tube. I just made jigs to drill it, then glued it into a tusk mount.

-

Thanks, I'll try again with some of the cloth covered wire and see if that won't get stuck. I used jig's and spring tube benders which worked ok for the aluminum but that brass I tried before was just determined to fold in on itself.