@Alva i have tried the same with the 3.6.0.beta2 +3 it worked as intended

Best posts made by Alva

-

RE: Multiple motion systemposted in General Discussion

Latest posts made by Alva

-

RE: Multiple motion systemposted in General Discussion

@dc42 Thank you. Confirmed as fixed from my side as well.

-

RE: Multiple motion systemposted in General Discussion

@dwuk3d Thank you so much for informing me. Sorry that i haven't got time to experiment further on this topic. I hope @dc42 and his team is looking into it .

-

RE: Multiple motion systemposted in General Discussion

@dwuk It was working in the 3.6.0-beta2+3 and it broke on the later versions. But i haven't tested the 3.6.0-beta4 yet though. Have you tested it?

-

RE: Multiple motion systemposted in General Discussion

@Alva @dc42 sorry for writing again, but will there be fix regarding this topic in the next version?

-

RE: Multiple motion systemposted in General Discussion

Any updates about this topic? My observation is 3.6.0-beta2+3 worked , but after that it is broken. Thank you

-

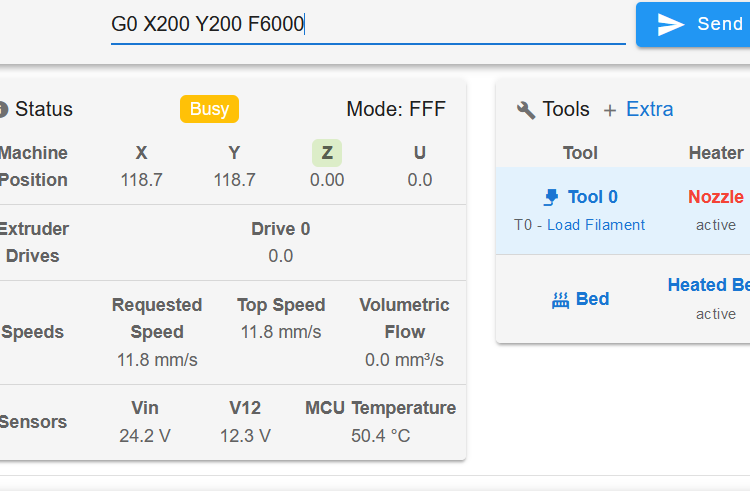

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

@Alva One more insight

requested speed is actually 100mm/s but it is moving in 11.8 mm/s.

-

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

@Alva 20250122_150146.mp4 20250122_150354.mp4

homeall.g

Attached is the two different behaviours happened. Between restarting and doing the homing.

PS: The printer is kinda test bench so please ignore the mess

thank you.

thank you.