@dc42 Thank you. Confirmed as fixed from my side as well.

Posts made by Alva

-

RE: Multiple motion systemposted in General Discussion

-

RE: Multiple motion systemposted in General Discussion

@dwuk3d Thank you so much for informing me. Sorry that i haven't got time to experiment further on this topic. I hope @dc42 and his team is looking into it .

-

RE: Multiple motion systemposted in General Discussion

@dwuk It was working in the 3.6.0-beta2+3 and it broke on the later versions. But i haven't tested the 3.6.0-beta4 yet though. Have you tested it?

-

RE: Multiple motion systemposted in General Discussion

@Alva @dc42 sorry for writing again, but will there be fix regarding this topic in the next version?

-

RE: Multiple motion systemposted in General Discussion

Any updates about this topic? My observation is 3.6.0-beta2+3 worked , but after that it is broken. Thank you

-

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

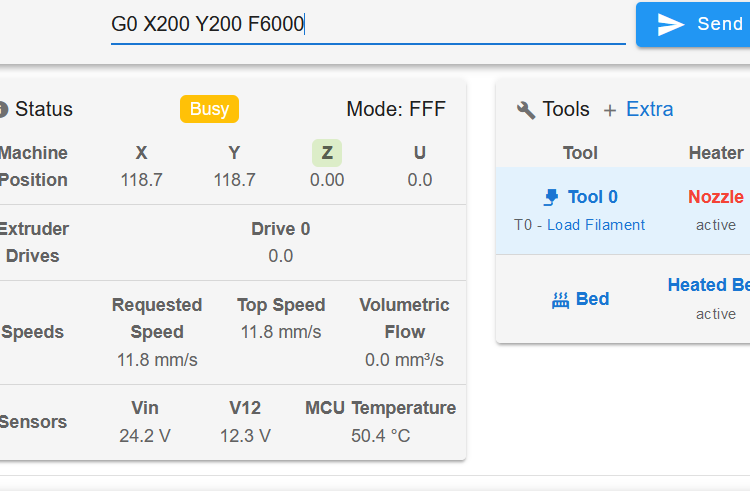

@Alva One more insight

requested speed is actually 100mm/s but it is moving in 11.8 mm/s.

-

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

@Alva 20250122_150146.mp4 20250122_150354.mp4

homeall.g

Attached is the two different behaviours happened. Between restarting and doing the homing.

PS: The printer is kinda test bench so please ignore the mess -

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

2025-01-22 14:55:26 [debug] === Diagnostics === 2025-01-22 14:55:26 [debug] RepRapFirmware for Duet 3 MB6HC version 3.6.0-beta.3 (2025-01-16 19:09:36) running on Duet 3 MB6HC v1.02 or 1.02a (standalone mode) 2025-01-22 14:55:26 [debug] Board ID: 08DJM-956BA-NA3TJ-6J1FJ-3S46P-198US 2025-01-22 14:55:26 [debug] Used output buffers: 2 of 40 (35 max) 2025-01-22 14:55:26 [debug] === RTOS === 2025-01-22 14:55:26 [debug] Static ram: 136892 2025-01-22 14:55:26 [debug] Dynamic ram: 128428 of which 0 recycled 2025-01-22 14:55:26 [debug] Never used RAM 78448, free system stack 154 words 2025-01-22 14:55:26 [debug] Tasks: 2025-01-22 14:55:26 [debug] NETWORK(1,ready,26.4%,143) 2025-01-22 14:55:26 [debug] ETHERNET(5,nWait 7,0.1%,318) 2025-01-22 14:55:26 [debug] HEAT(3,nWait 6,0.0%,361) 2025-01-22 14:55:26 [debug] Move(4,nWait 6,0.0%,215) 2025-01-22 14:55:26 [debug] TMC(4,nWait 6,3.1%,341) 2025-01-22 14:55:26 [debug] CanReceiv(6,nWait 1,0.0%,794) 2025-01-22 14:55:26 [debug] CanSender(5,nWait 7,0.0%,334) 2025-01-22 14:55:26 [debug] CanClock(7,delaying,0.0%,350) 2025-01-22 14:55:26 [debug] MAIN(1,running,70.3%,103) 2025-01-22 14:55:26 [debug] IDLE(0,ready,0.0%,29) 2025-01-22 14:55:26 [debug] USBD(3,blocked,0.0%,144) 2025-01-22 14:55:26 [debug] , total 100.0% Owned mutexes: 2025-01-22 14:55:26 [debug] HTTP(MAIN) 2025-01-22 14:55:26 [debug] === Platform === 2025-01-22 14:55:26 [debug] Last reset 00:06:41 ago, cause: power up 2025-01-22 14:55:26 [debug] Last software reset at 2025-01-20 15:48, reason: User, Gcodes spinning, available RAM 78764, slot 2 2025-01-22 14:55:26 [debug] Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a 2025-01-22 14:55:26 [debug] Error status: 0x00 2025-01-22 14:55:26 [debug] MCU temperature: min 49.3, current 50.2, max 50.3 2025-01-22 14:55:26 [debug] Supply voltage: min 23.7, current 24.1, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes 2025-01-22 14:55:26 [debug] 12V rail voltage: min 12.1, current 12.2, max 12.5, under voltage events: 0 2025-01-22 14:55:26 [debug] Heap OK, handles allocated/used 99/6, heap memory allocated/used/recyclable 2048/1804/1708, gc cycles 0 2025-01-22 14:55:26 [debug] Events: 0 queued, 0 completed 2025-01-22 14:55:26 [debug] Date/time: 2025-01-22 14:55:26 [debug] 2025-01-22 14:55:26 2025-01-22 14:55:26 [debug] Slowest loop: 208.16ms; fastest: 0.06ms 2025-01-22 14:55:26 [debug] USB interrupts 3 2025-01-22 14:55:26 [debug] === Storage === Free file entries: 17 2025-01-22 14:55:26 [debug] SD card 0 detected, interface speed: 25.0MBytes/sec 2025-01-22 14:55:26 [debug] SD card longest read time 3.3ms, write time 3.8ms, max retries 0 2025-01-22 14:55:26 [debug] === Move === Segments created 12, maxWait 221286ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.12ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 2025-01-22 14:55:26 [debug] Pos req/act/dcf: 1.00/1/-0.00 0.00/0/-0.00 2112.00/2112/0.00 0.00/0/0.00 2025-01-22 14:55:26 [debug] next step interrupt due in 273 ticks, disabled 2025-01-22 14:55:26 [debug] Driver 0: standstill, SG min 0, mspos 232, reads 41018, writes 15 timeouts 1 2025-01-22 14:55:26 [debug] Driver 1: standstill, SG min 0, mspos 408, reads 41016, writes 15 timeouts 1 2025-01-22 14:55:26 [debug] Driver 2: standstill, SG min 0, mspos 904, reads 41016, writes 15 timeouts 1 2025-01-22 14:55:26 [debug] Driver 3: standstill, SG min n/a, mspos 8, reads 41020, writes 11 timeouts 1 2025-01-22 14:55:26 [debug] Driver 4: standstill, SG min n/a, mspos 8, reads 41025, writes 11 timeouts 1 2025-01-22 14:55:26 [debug] Driver 5: standstill, SG min n/a, mspos 4, reads 41025, writes 11 timeouts 1 2025-01-22 14:55:26 [debug] Phase step loop runtime (us): min=0, max=84, frequency (Hz): min=750, max=2533 2025-01-22 14:55:26 [debug] === DDARing 0 === Scheduled moves 15, completed 15, LaErrors 0, Underruns [0, 0, 0] 2025-01-22 14:55:26 [debug] Segments left 0, axes/extruders owned 0x8000000f, drives owned 0x8000000f 2025-01-22 14:55:26 [debug] Code queue is empty 2025-01-22 14:55:26 [debug] === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] 2025-01-22 14:55:26 [debug] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 2025-01-22 14:55:26 [debug] Code queue is empty 2025-01-22 14:55:26 [debug] === Heat === 2025-01-22 14:55:26 [debug] Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1 -1 -1 -1 -1, ordering er 2025-01-22 14:55:26 [debug] Heater 0 is on, I-accum = 0.3 2025-01-22 14:55:26 [debug] Heater 1 is on, I-accum = 0.0 2025-01-22 14:55:26 [debug] === GCodes === 2025-01-22 14:55:26 [debug] Movement locks held by HTTP, HTTP 2025-01-22 14:55:26 [debug] HTTP is ready with "M122 B{boards[iterations].canAddress}" in state(s) 0 0 24, running macro 2025-01-22 14:55:26 [debug] Telnet is idle in state(s) 0 2025-01-22 14:55:26 [debug] File is idle in state(s) 0 2025-01-22 14:55:26 [debug] USB is idle in state(s) 0 2025-01-22 14:55:26 [debug] Aux is idle in state(s) 0 2025-01-22 14:55:26 [debug] Trigger is idle in state(s) 0 2025-01-22 14:55:26 [debug] Queue is idle in state(s) 0 2025-01-22 14:55:26 [debug] LCD is idle in state(s) 0 2025-01-22 14:55:26 [debug] SBC is idle in state(s) 0 2025-01-22 14:55:26 [debug] Daemon is idle in state(s) 0 2025-01-22 14:55:26 [debug] Aux2 is idle in state(s) 0 2025-01-22 14:55:26 [debug] Autopause is idle in state(s) 0 2025-01-22 14:55:26 [debug] File2 is idle in state(s) 0 2025-01-22 14:55:26 [debug] Queue2 is idle in state(s) 0 2025-01-22 14:55:26 [debug] === CAN === 2025-01-22 14:55:26 [debug] Messages queued 3061, received 7000, lost 0, ignored 0, errs 0, boc 0 2025-01-22 14:55:26 [debug] Longest wait 6ms for reply type 6024, peak Tx sync delay 275, free buffers 50 (min 49), ts 1650/1650/0 2025-01-22 14:55:26 [debug] Tx timeouts 0,0,0,0,0,0 2025-01-22 14:55:26 [debug] === Network === 2025-01-22 14:55:26 [debug] Slowest loop: 187.18ms; fastest: 0.03ms 2025-01-22 14:55:26 [debug] Responder states: 2025-01-22 14:55:26 [debug] MQTT(0) 2025-01-22 14:55:26 [debug] HTTP(0) 2025-01-22 14:55:26 [debug] HTTP(0) 2025-01-22 14:55:26 [debug] HTTP(0) 2025-01-22 14:55:26 [debug] HTTP(0) 2025-01-22 14:55:26 [debug] HTTP(0) 2025-01-22 14:55:26 [debug] HTTP(0) 2025-01-22 14:55:26 [debug] FTP(0) 2025-01-22 14:55:26 [debug] Telnet(0) 2025-01-22 14:55:26 [debug] Telnet(0) 2025-01-22 14:55:26 [debug] HTTP sessions: 1 of 8 2025-01-22 14:55:26 [debug] = Ethernet = Interface state: active 2025-01-22 14:55:26 [debug] Error counts: 0 0 0 0 0 0 Socket states: 2025-01-22 14:55:26 [debug] 2 2025-01-22 14:55:26 [debug] 2 2025-01-22 14:55:26 [debug] 2 2025-01-22 14:55:26 [debug] 2 2025-01-22 14:55:26 [debug] 2 2025-01-22 14:55:26 [debug] 2 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] === WiFi === Interface state: disabled Module is disabled Failed messages: pending 0, notrdy 0, noresp 0 2025-01-22 14:55:26 [debug] Socket states: 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] 0 2025-01-22 14:55:26 [debug] === Multicast handler === Responder is inactive, messages received 0, responses 0 -

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

2025-01-22 14:55:28 [debug] Diagnostics for board 121: 2025-01-22 14:55:28 [debug] Duet TOOL1LC rev 1.1 or later firmware version 3.6.0-beta.3 (2025-01-15 18:55:15) Bootloader ID: SAMC21 bootloader version 2.4 (2021-12-10) All averaging filters OK 2025-01-22 14:55:28 [debug] Never used RAM 8056, free system stack 100 words Tasks: Move(3,nWait 7,0.0%,96) TMC(2,nWait 6,3.7%,52) HEAT(2,nWait 6,0.3%,96) CanAsync(5,nWait 4,0.0%,54) CanRecv(3,nWait 1,0.0%,70) CanClock(5,nWait 1,0.0%,58) ACCEL(3,nWait 6,0.0%,52) MAIN(1,running,91.2%,318) IDLE(0,ready,0.0%,26) AIN(2,delaying,4.8%,112), total 100.0% Owned mutexes: Last reset 00:06:42 ago, cause: power up 2025-01-22 14:55:28 [debug] Last software reset data not available 2025-01-22 14:55:28 [debug] Moves scheduled 3, hiccups 1 (0.12/0.12ms), segs 3, step errors 0 (types 0x0), maxLate 0 maxPrep 106, ebfmin 0.00 max 0.00 Peak sync jitter 0/5, peak Rx sync delay 228, resyncs 0/0, no timer interrupt scheduled, next step interrupt due in 4281978413 ticks, disabled VIN voltage: min 23.8, current 24.0, max 24.2 MCU temperature: min 36.1C, current 41.2C, max 41.4C 2025-01-22 14:55:28 [debug] Driver 0: pos 41121, 2056.0 steps/mm, standstill, SG min 0, read errors 0, write errors 0, ifcnt 14, reads 43022, writes 1, timeouts 0, DMA errors 0, CC errors 0 2025-01-22 14:55:28 [debug] Last sensors broadcast 0x00000002 found 1 238 ticks ago, 0 ordering errs, loop time 0 CAN messages queued 6995, send timeouts 0, received 3061, lost 0, ignored 0, errs 0, boc 0, free buffers 18, min 18, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 306, adv 35865/37161 2025-01-22 14:55:28 [debug] Accelerometer: LIS3DH, status: 00 I2C bus errors 0, naks 0, contentions 0, other errors 0 2025-01-22 14:55:29 [debug] [diagnostic.g] Done /macros/printing/diagnostic.g 2025-01-22 14:55:29 [debug] [STOP] Properly closing log file 2025-01-22 14:55:29 [debug] [LOGS] Closing previous log file 2025-01-22 14:55:29 [info] Event logging stopped -

RE: Movement speed of the axes reduced abruptly.posted in General Discussion

@Notepad The values were working fine before without any problem. However i have changed the values according to your suggestion and it is behaving still the same. Was working for some minutes without any problem. The steps that i did.

- Changed the jerk and the acceleration values as suggested above.

- Homed the printer(It was homing in the intended speed).

- Started the print , started moving in intended speed.

- Canceled the print.

- Did homing again and it started behaving weird again. Speed reduced more than half.

When restarting the print it behaves normal for sometime.

-

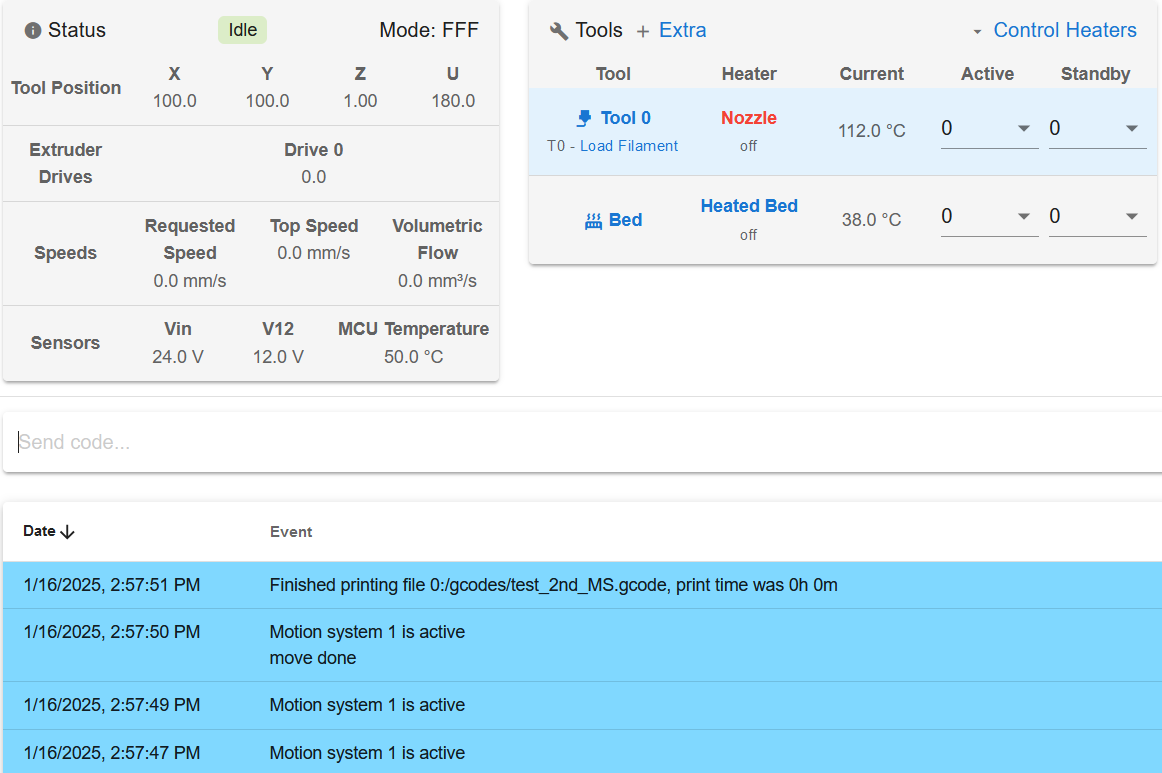

Movement speed of the axes reduced abruptly.posted in General Discussion

Hello,

I have updated my machine with the newest 3.6.0-beta3 and seeing an inconsistent behaviour in the speed of the axes. The behaviour is really inconsistent. I couldnt find the pattern. Some times restarting the machine fixes the behaviour.

config(4).g . attached is the config.g . Any insights about the issue. Thank you. -

RE: Multiple motion systemposted in General Discussion

@o_lampe My requirement is to utilize the unused axes during printing, with their movement controlled via daemon.g and triggered by a flag. My understanding of multiple motion systems is that the unused axes should be accessible to the other motion system. However, the error I am encountering indicates that the unused axes are still being treated as part of the motion system responsible for the print job.

-

RE: Multiple motion systemposted in General Discussion

@T3P3Tony Tested the above mentioned testing procedure and got the same error as 3.6.0.beta2 + 5.

-

RE: Multiple motion systemposted in General Discussion

@Alva i have tried the same with the 3.6.0.beta2 +3 it worked as intended

-

RE: Multiple motion systemposted in General Discussion

@Alva U axis was trying to use only in the second motion system. so motion system 0 and motion system 1 are not able to execute simultaneously.

thank you.

thank you.