Hi everyone,

First post here, I thought I'd present my machine first because I think I might have a few questions about how to use/improve/pimp my duet board later.

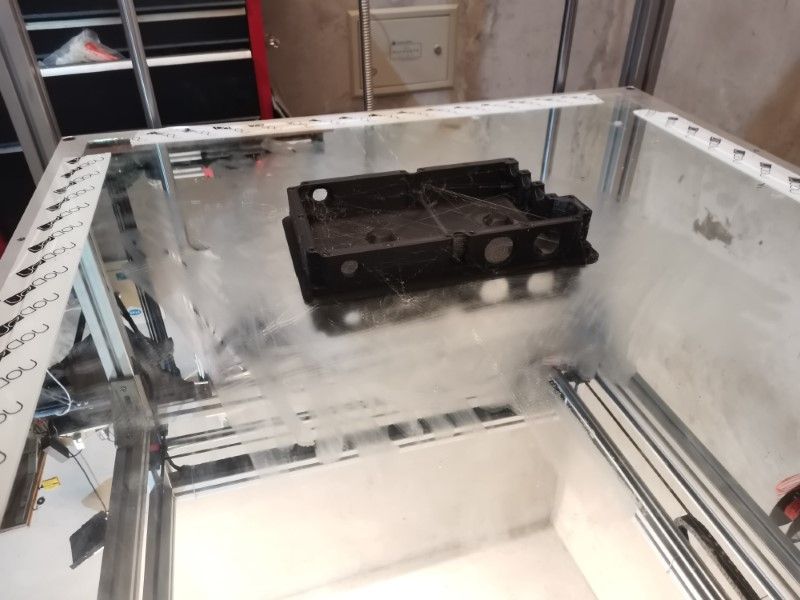

So, basically my goal is to build a big printer. So far the print volume measures 720 x 720 x 600 mm or so. The frame is made out of 4545 aluminum extrusions, it is entirely my design but I did build a MPCNC before, which was my inspiration for making this one, hence the tubes.

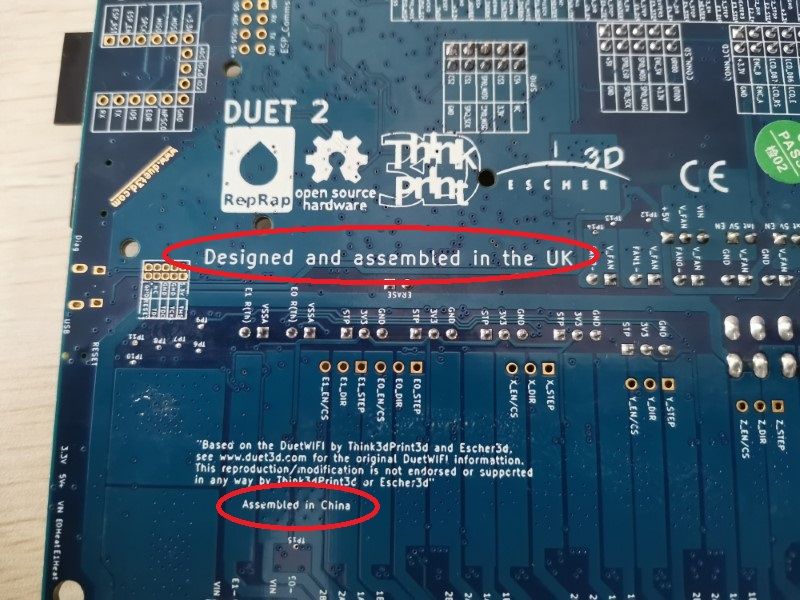

Anyway, this is my first time using a Duet, my other machines were using the traditional Arduino Mega/Ramps/Marlin, which worked nicely but, well, they did their time. So far I'm pretty pleased with how the Duet board works, it is really convenient to use, though editing the firmware is maybe a bit less intuitive since you use gcode all along instead of commenting/uncommenting stuff in a more understandable language. But I guess I'll get used to it eventually.

But again, the list of upsides is long enough that I don't really care about that, this board is awesome so kudos to the team who designed it.

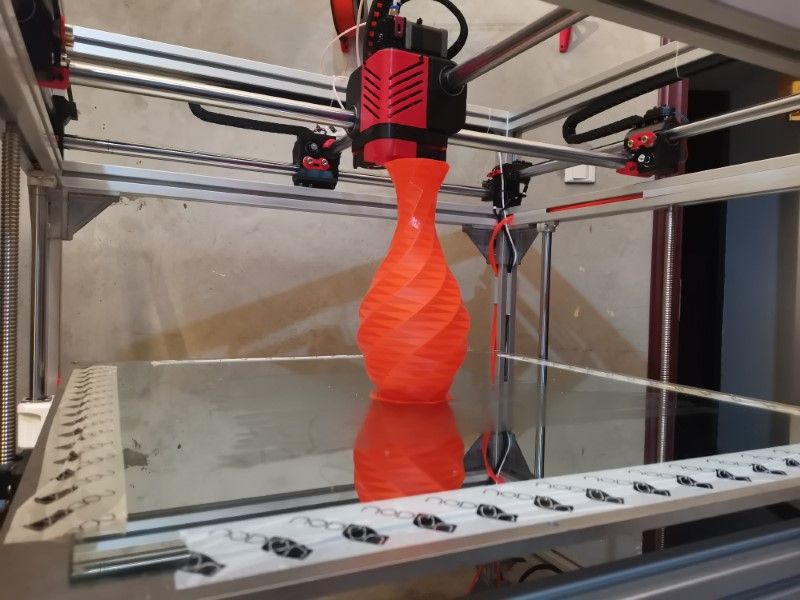

I started this build 2 months ago and it made its first test print yesterday. Here is how it looks like so far:

The machine itself measures 1m x 1m x 1m40 so it takes quite some space in the shop. The bed is made of a big 10 mm plate of cast aluminum. It will be heated by 9 silicon pads of 300W each, so about 2700W of heating power (goal is for the plate to reach the temp quickly). I'm currently using the double Z axis feature, which works well, but I'll probably add the extension board and go for triple Z axis later.

The bed is very heavy (30kg), but the motor have enough power to lift it pretty quickly, it takes less than 30 seconds to travel the 600+ mm which is actually quite impressive to see IRL since the machine is big. I had to go to 8 microstepping in order to do that reliably, but it doesn't matter in terms of resolution since I'm using a 3:1 belt reduction as well as 4mm per turn pitch ballscrews so in the end that's 1200steps per mm, way more than necessary.

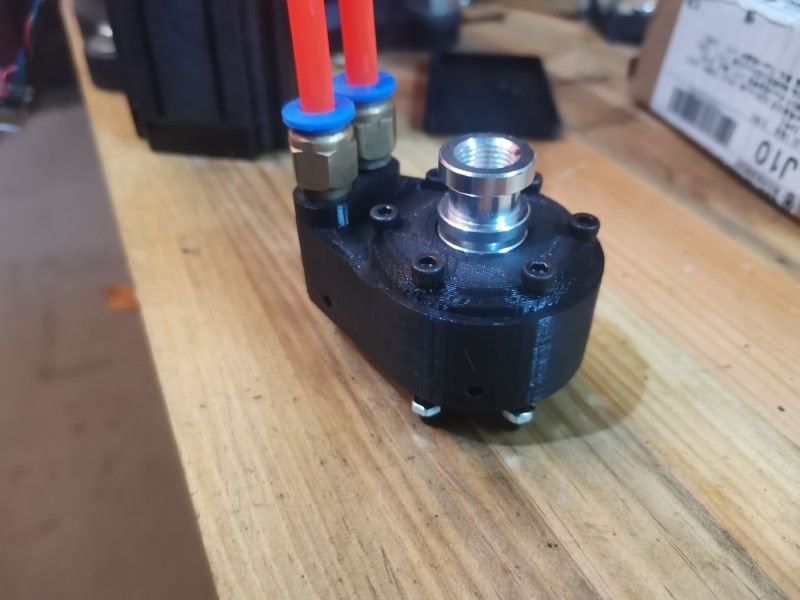

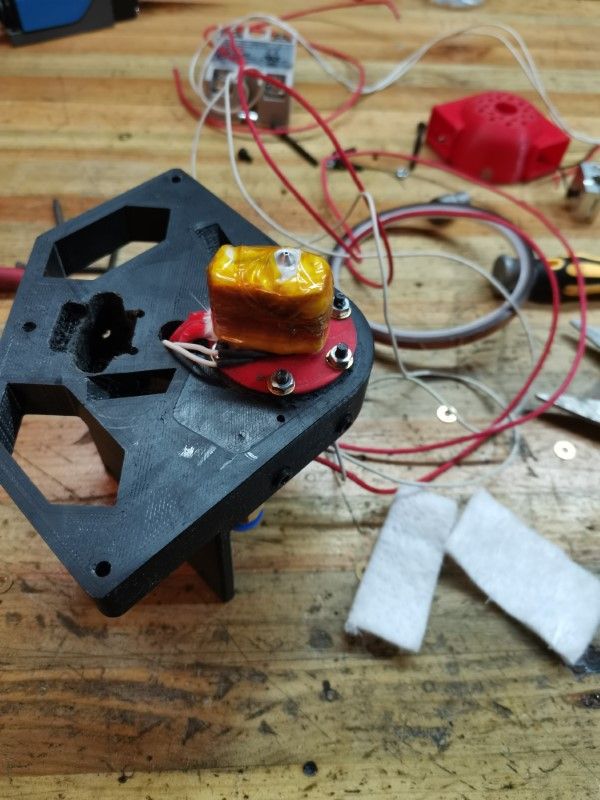

The print head is water cooled, because from my experience it makes a big difference on large format printers. I've designed a fully 3D printed nozzle system using just a regular E3Dv6 extrusion system. So far it seems to work well. That's not the first watercooling system I designed this way, my previous one lasted a few years without any issue so I know this works well

The heating block is a full copper volcano with a stainless steel nozzle, insulated with aerogel sheets.

The part cooling fans are blowing 360 degree around the nozzle to hopefully avoid any blind spot. The aerogel insulation is very useful here because otherwise the fans would cool the hotend, which obviously wouldn't be ideal

The Z probe is using a BL touch.

Also added a LED strip to better see what's going on during printing:

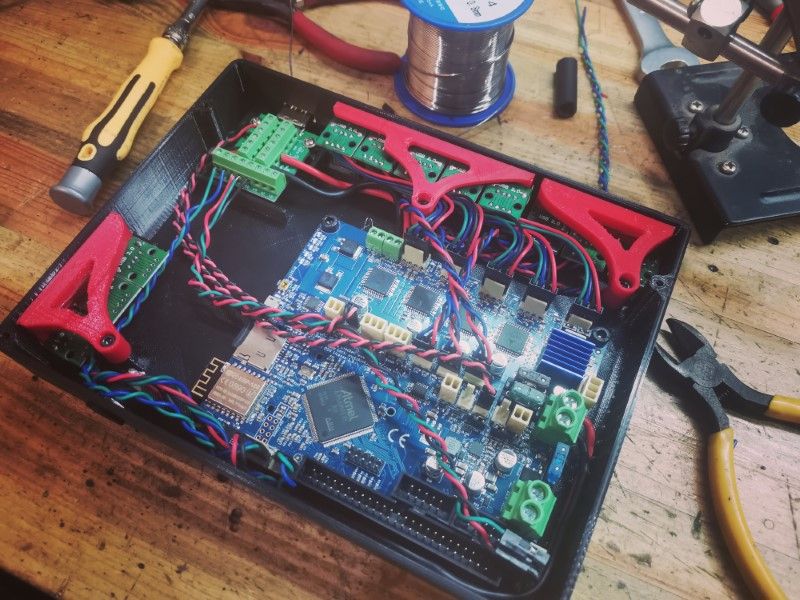

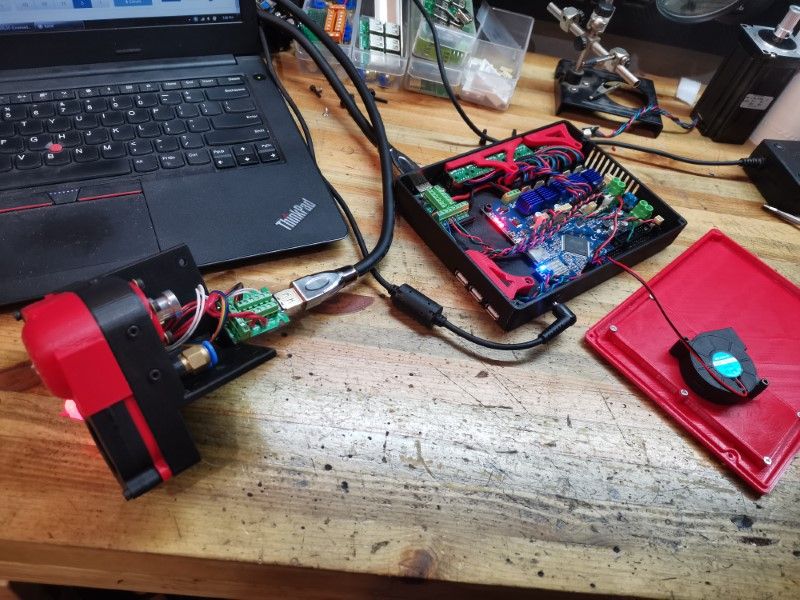

I took a lot of care designing a nice casing to protect my marvelous Duet board, since it deserved it:

It features active cooling with a blower fan placed after a dust filter:

I needed active cooling because the Z drivers were running too hot, the bed is heavy so I had to push the motor drivers up to 2.4Amps.

I tried to be original here and used something unorthodox for wiring: using USB and HDMI cables. USB is used for the motors, the endstops, the paneldue and the heating bed relay control, and HDMI is used for the whole print head (heating element, temp sensor, BLtouch, extruder motor, LED light, fans).

It makes wiring extremely easy, and so far it seems to work really well. I'll see in the long run how reliable this is, now is a bit too soon to give a proper feedback.

Anyway, first successful print attempt yesterday and it looks really nice for a first try:

Also a short video of the first print:

https://youtu.be/mw_b87EWHZk

Here is the build thread, in case anyone wants to follow

https://forum.v1engineering.com/t/mpcnc-made-in-china-new-build/19393

I'm really pleased with my Duet so far, it's a great board!

Thanks for reading and see you on the forum!

and yes, HDMI cables are a surprisingly good way to connect things, did you get the breakout boards off the shelf or make them yourself?

and yes, HDMI cables are a surprisingly good way to connect things, did you get the breakout boards off the shelf or make them yourself?