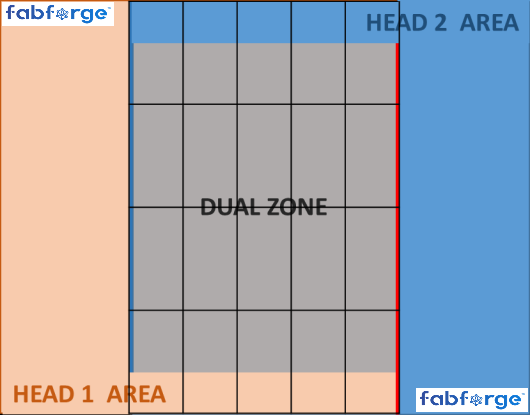

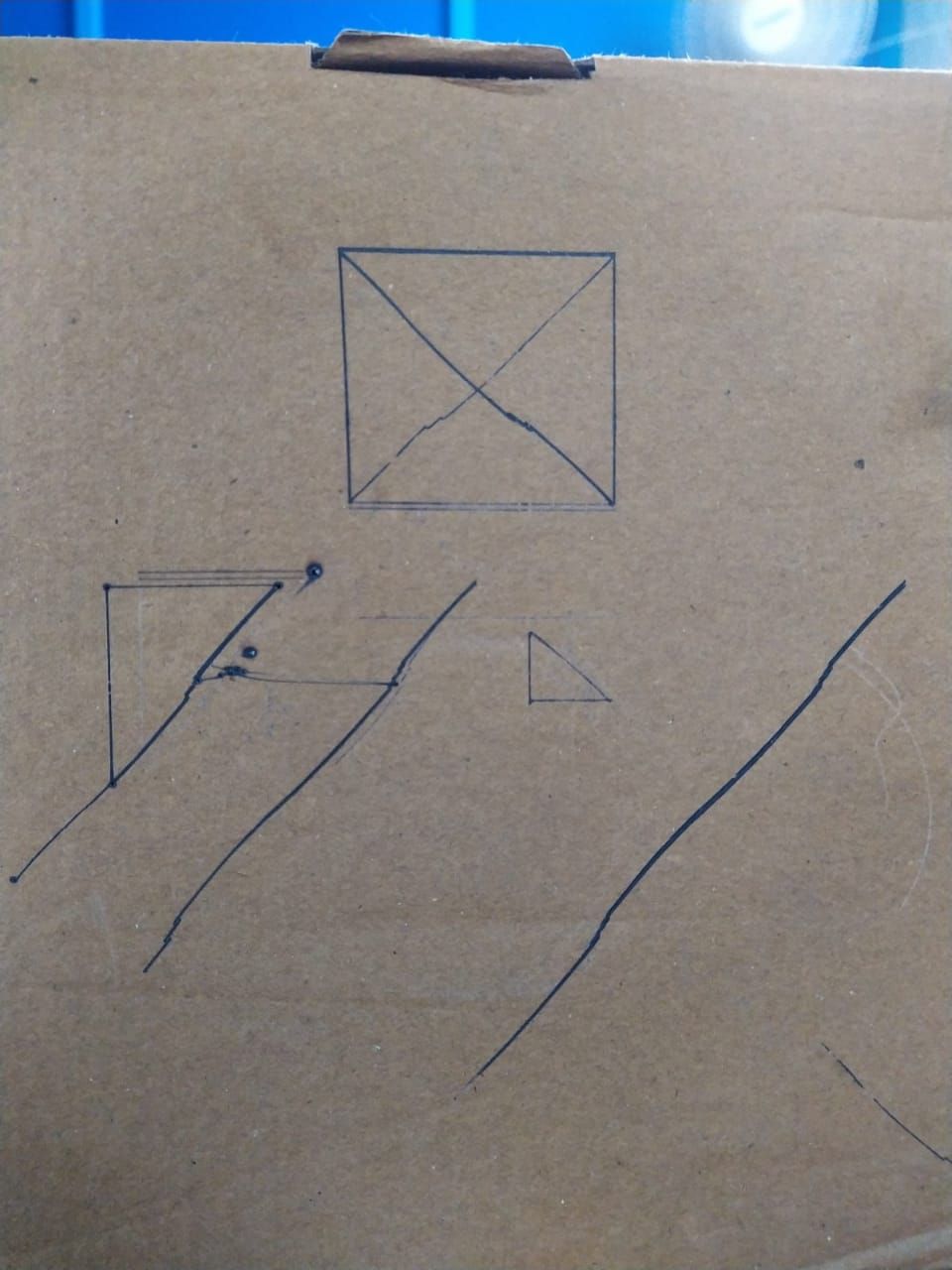

@Phaedrux I adjusted bed size in slicer and mentioned tool offset

and created custom bed image to avoid placing the object in wrong position in the bed for tool heads.

Best posts made by adhanabal

-

RE: X axis Tool head Offsetsposted in Tuning and tweaking

-

separate idle current for extruder motorsposted in Firmware wishlist

hello all

is it possible to keep only xyz axis motors in defined idle current ,

i want to keep extruder motor to become zero idle current,or is it possible that m571 command i can define for individual extruders for some operations in which i require to allocate different outputs for different extruders,

board; duet3 6hc, firmware 3.3

please help

@dc42 -

RE: Homing with Z-max endstopposted in Tuning and tweaking

@fcwilt yes from config tool and next time i will upload the files in the mentioned way.

-

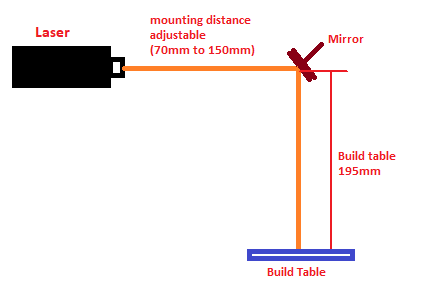

SLS printer Build-Stepper galvoposted in My Duet controlled machine

Hello all

Mainboard: Duet 3 6HC

Im working on SLS 3d printer project, its almost complete,

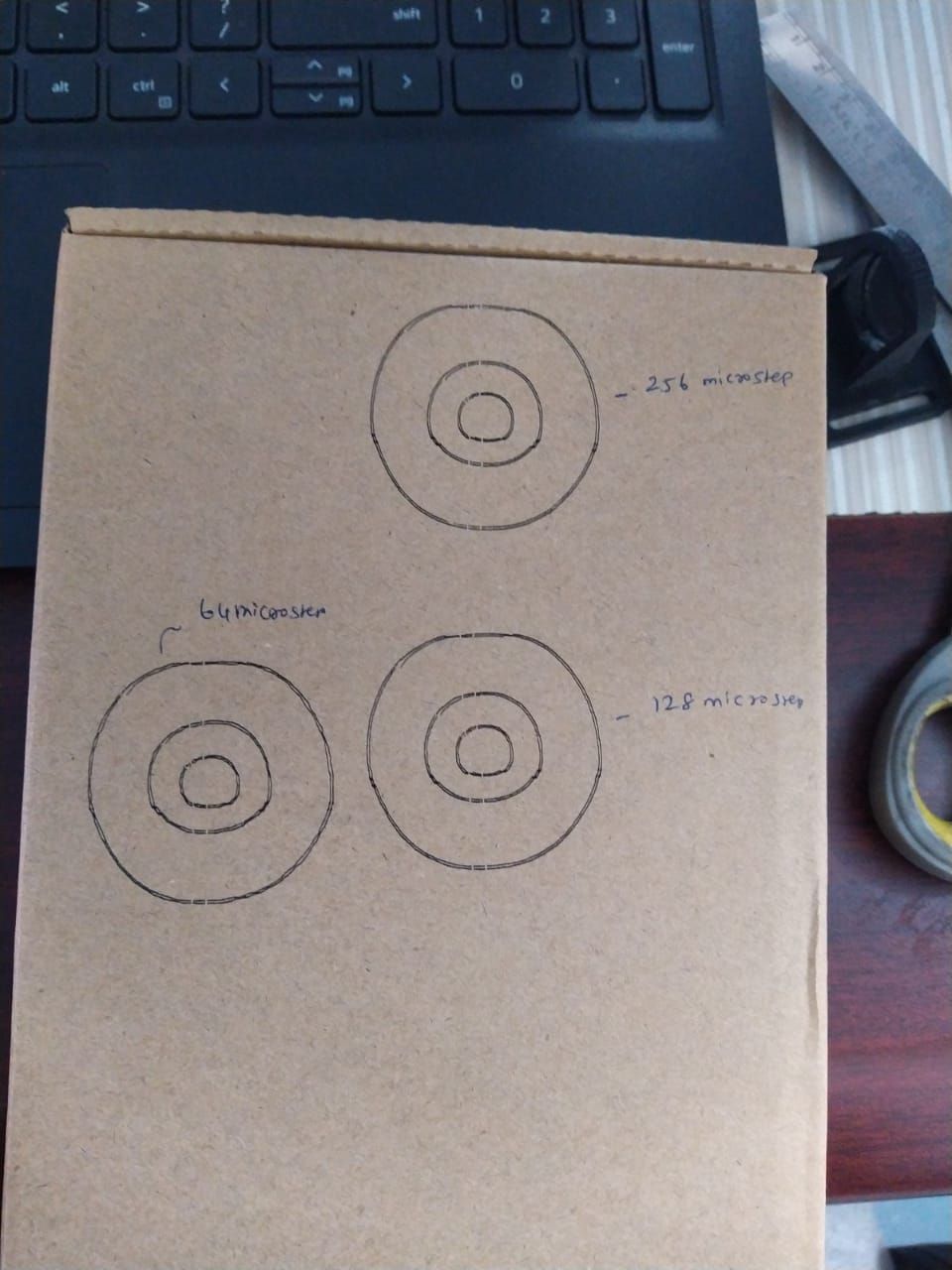

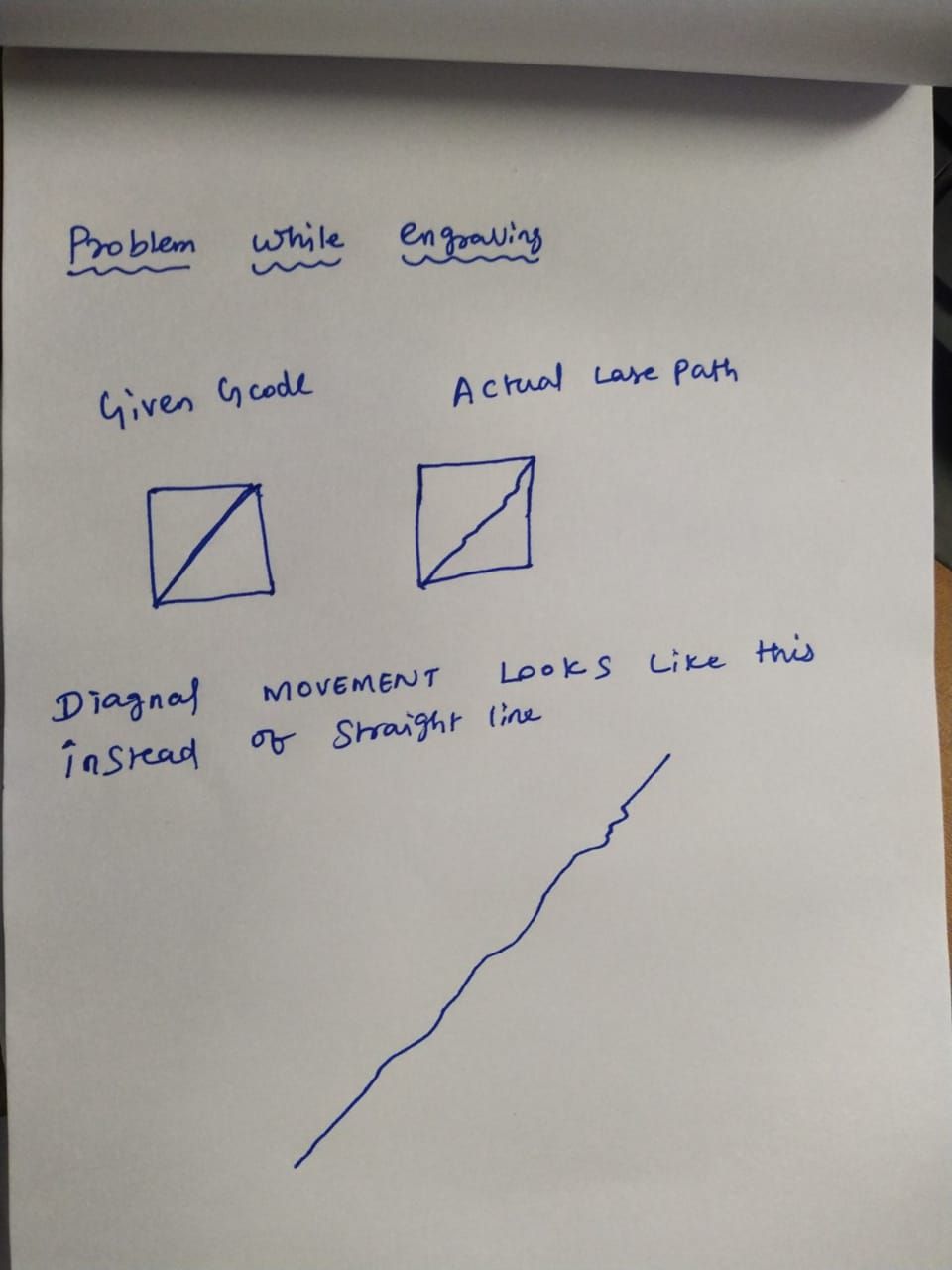

I have an issue in X & Y using Nema 17 1.8'motors,

I use stepper motors to move mirrors on X&Y (both mirrors mounted directly on the motor shaft on X & Y)

my working distance is around 195mm from Y-Mirror,

So as per the steps per mm calculation, My steps per mm is 40 @ 256microstepping,

this system not working well, especially when i draw a circle it turns to oval with un even shape, i have attached some sample photos, can anyone give me idea?

-

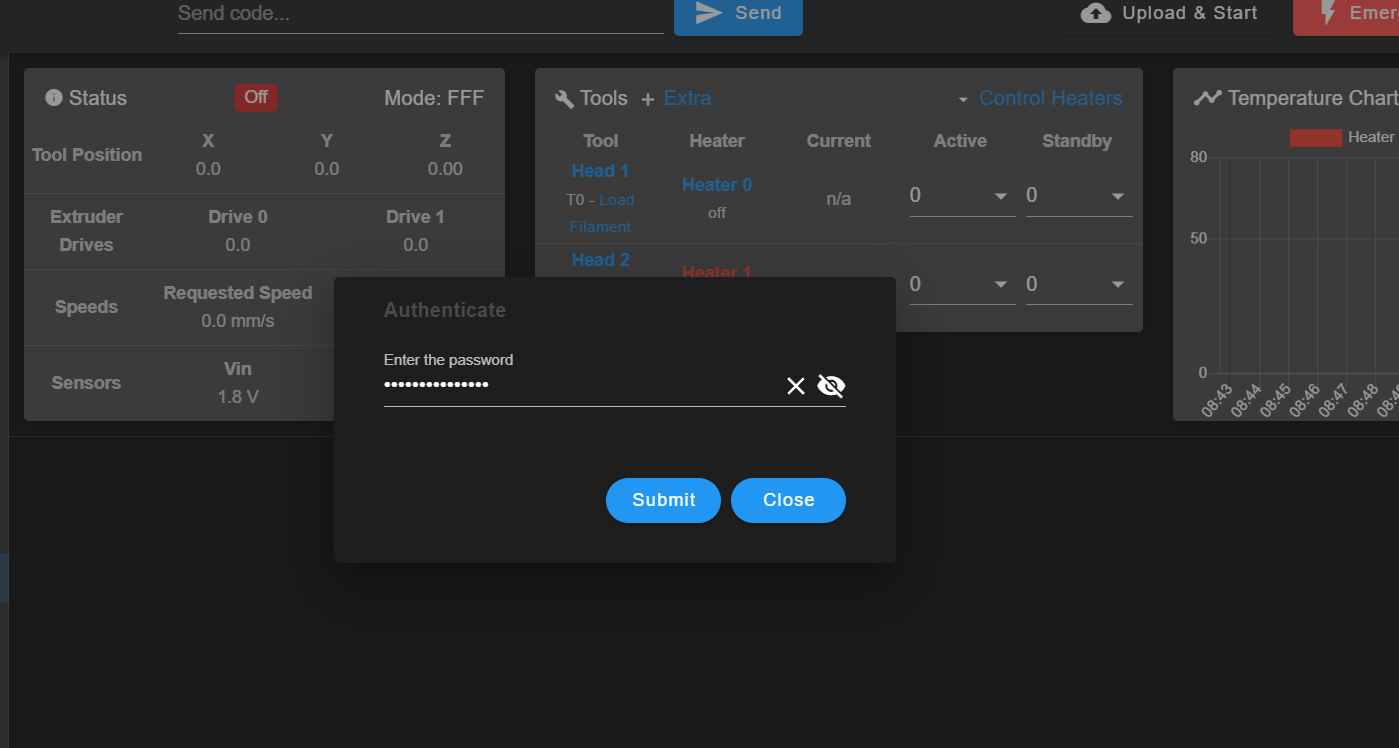

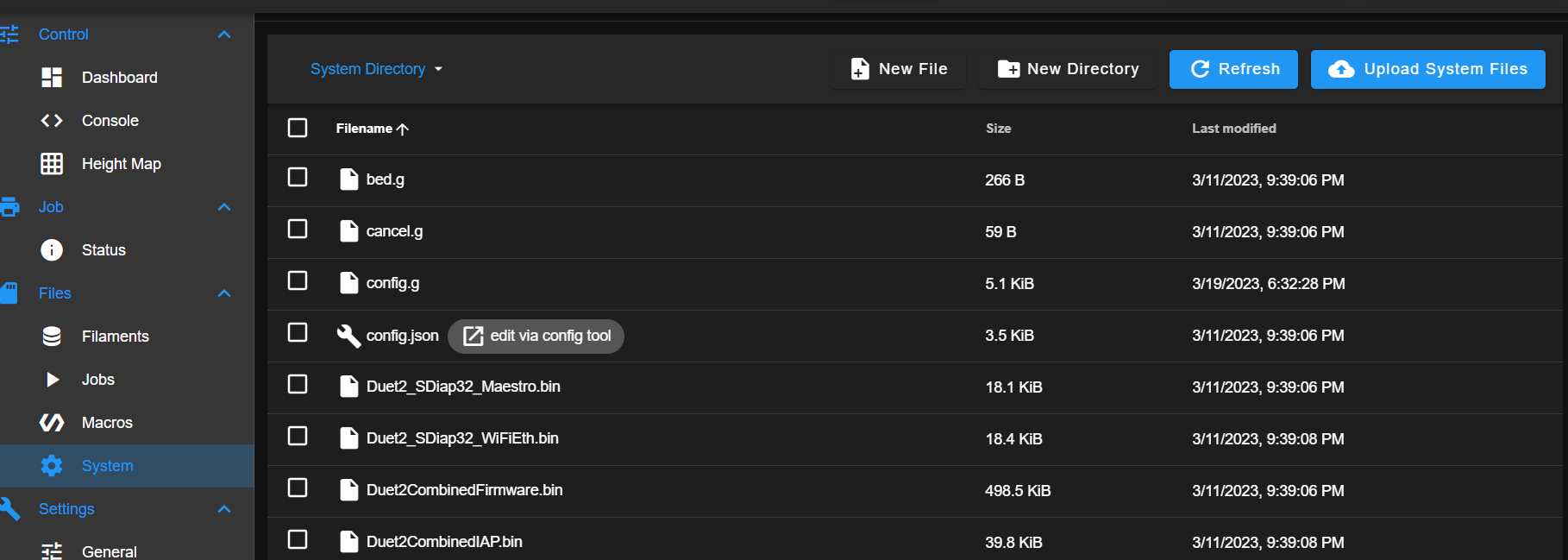

System files successfully lockedposted in Duet Web Control

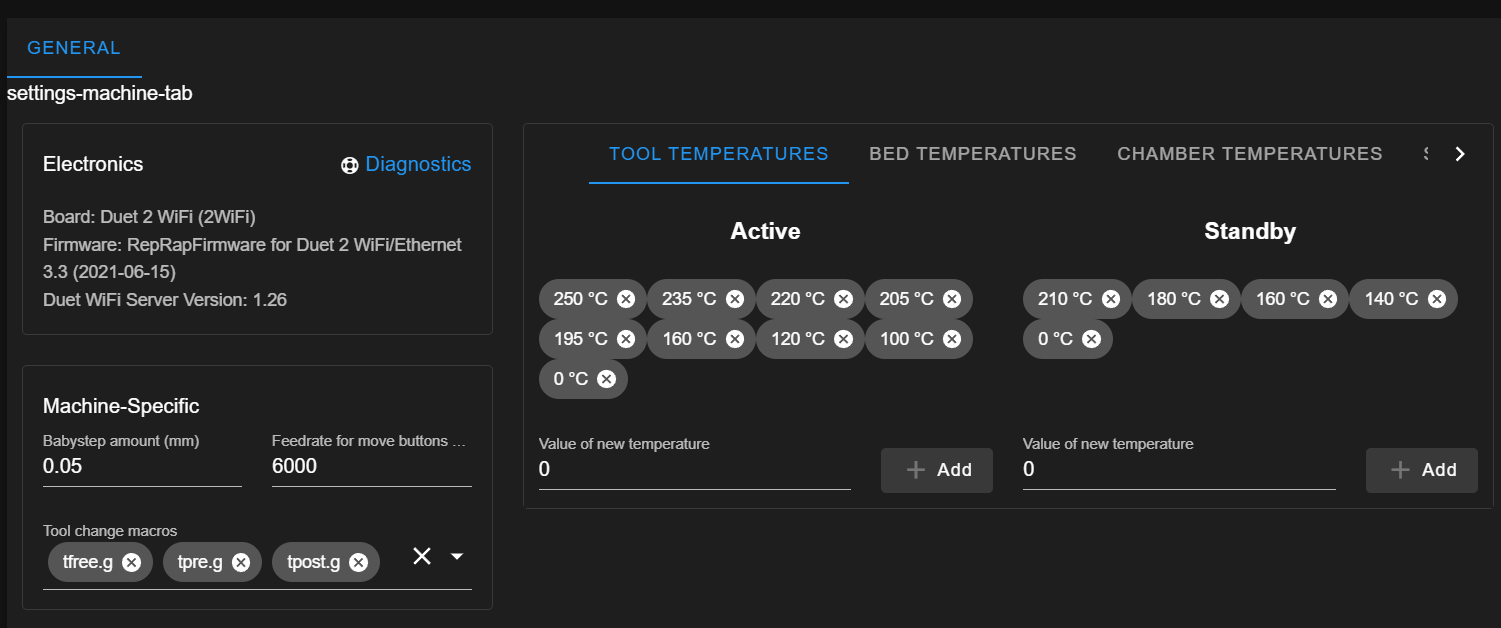

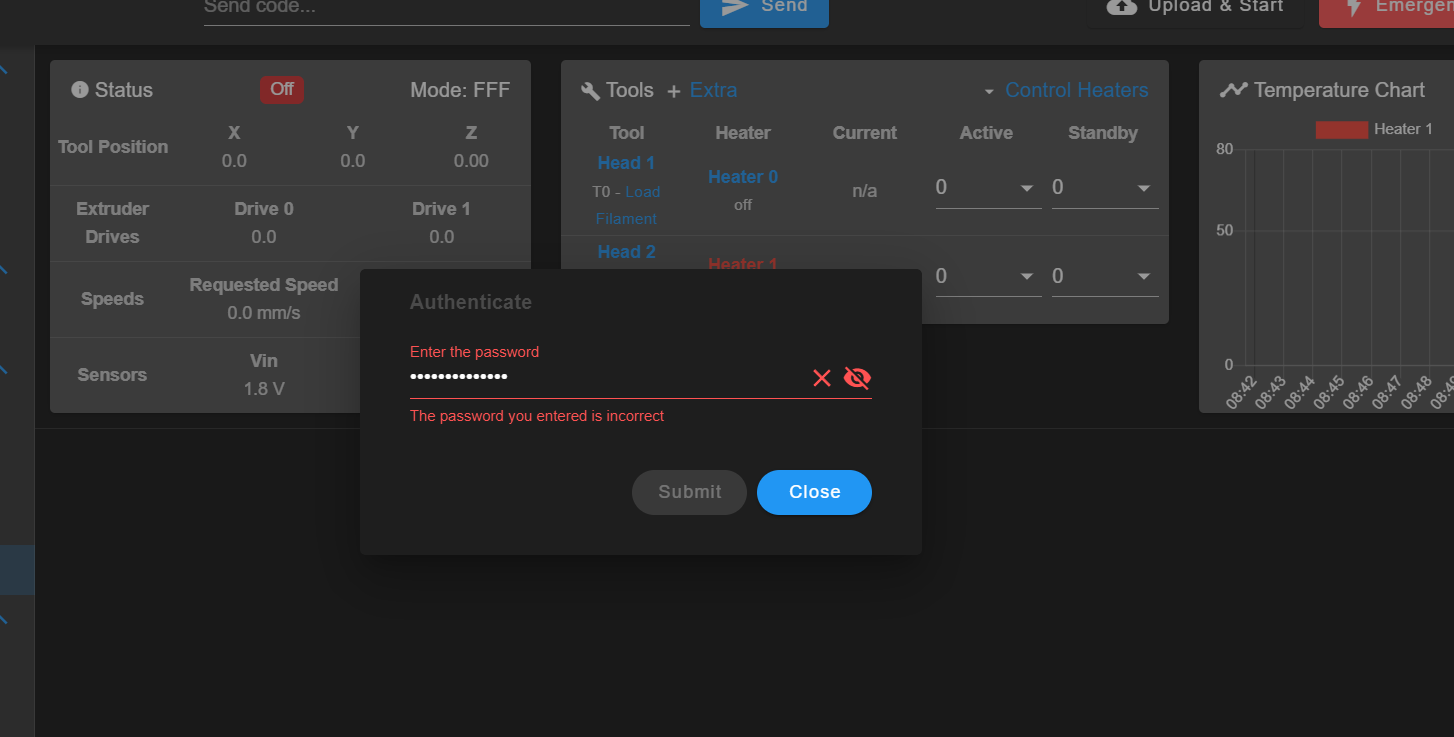

I wanted to avoid unintentional changes to config file, so locked out system folder with password by editing DWC source code. This protection is only for web interface for now. & DWC-3.4.5 only.

Also we remove Install updates button from - Machine specific tab

But -- if someone reads SD card in the PC, they can see config files.

Let me know if we should work on RRF 3.4.5 for locking the sys folder ,

-

Chamber heater tuningposted in Tuning and tweaking

Hi all

I'm using IR heaters to heat my chamber,

I placed my temperature sensor far from heater to get perfect chamber temperature readings,

Problem is heater going to fault, stating temperature raise is too low, 0.1deg/sec

How can I overcome this issue,

I tried PID tuning but it was taking 2 hours to reach phase 3 (measuring) , and didn't complete the tuning.

Any guidance please -

RE: System files successfully lockedposted in Duet Web Control

@jay_s_uk yes I ll do that.

Still finding an easy way to edit with users own password.

Will upload things once found.

Latest posts made by adhanabal

-

Duet3 6HC to raspberry pi 5posted in Duet Hardware and wiring

Where can i find duet3 6HC to SBC ribbon cable pinouts? Do duet use all 26 pins to communicate to raspberry pi?

-

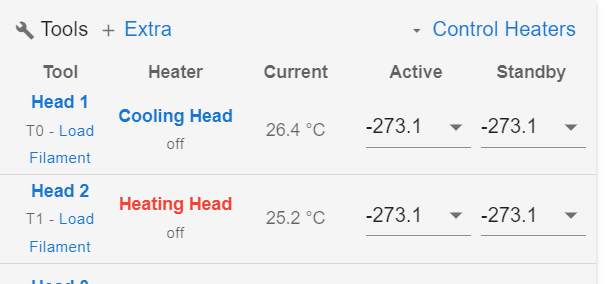

RE: Web interface showing -273.1 in Active and Standbyposted in Duet Web Control

@chrishamm said in Web interface showing -273.1 in Active and Standby:

M568 P0 S0 R0

It worked thank you

-

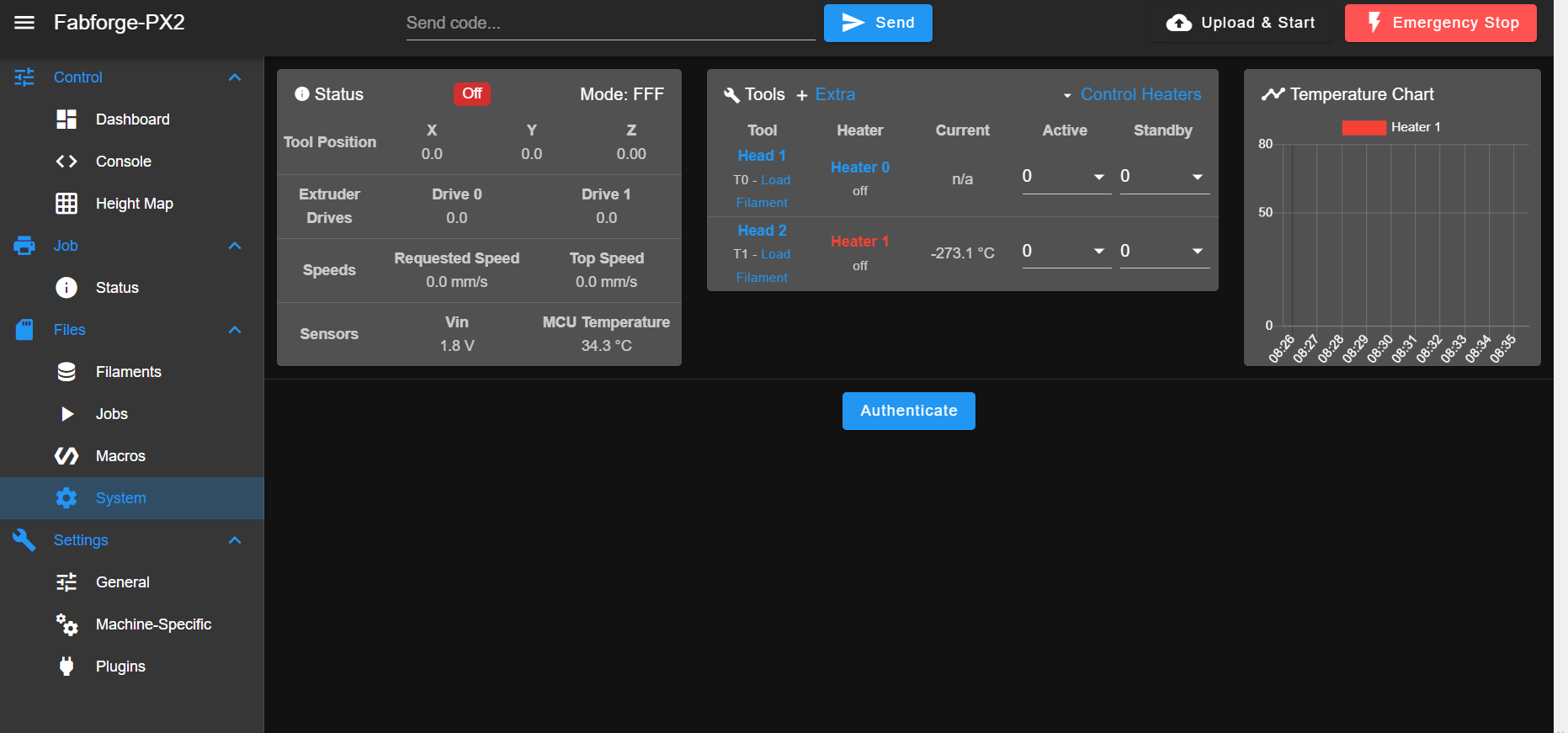

RE: Web interface showing -273.1 in Active and Standbyposted in Duet Web Control

@adhanabal How to make it show as Zero?

; Sensors

M308 S0 P"temp0" Y"thermistor" A"Cooling Head" T100000 B4725 C7.06e-8 ; configure sensor #1

M308 S1 P"temp1" Y"thermistor" A"Heating Head" T100000 B4725 C7.06e-8 ; configure sensor #0

M308 S2 P"temp2" Y"thermistor" A"Heating Bed" T100000 B4725 C7.06e-8 ; configure sensor #1; Heaters

M950 H0 C"out0" T0 ; create heater #1

M143 S38 ; configure heater monitor #0 for heater #1

M307 H0 R2.43 D5.5 E1.35 K0.56 B0 I1 ; configure model of heater #1

M950 H1 C"out1" T1 ; create heater #0

M143 S250 ; configure heater monitor #0 for heater #0

M307 H1 R2.43 D5.5 E1.35 K0.56 B1 ; configure model of heater #0

M950 H2 C"out2" T2 ; create heater #1

M143 S85 ; configure heater monitor #0 for heater #1

M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1; Heated beds

M140 P0 H2 ; configure heated bed #0

; Tools

M563 P0 S"Head 1" D0 H0 ; create tool #0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

M563 P1 S"Head 2" D0 H1 ; create tool #1

G10 P1 X45 Y0 Z0 ; set tool 0 axis offsets

M563 P2 S"Head 3" D0 ; create tool #2

G10 P2 X90 Y0 Z0 ; set tool 0 axis offsets

M563 P3 S"Head 4" D0 F3 ; create tool #3

G10 P3 X135 Y0 Z0 ; set tool 0 axis offsets -

Web interface showing -273.1 in Active and Standbyposted in Duet Web Control

Hi

Why it is showing like this instead of 0? RRF version 3.5.4

-

Chamber heater tuningposted in Tuning and tweaking

Hi all

I'm using IR heaters to heat my chamber,

I placed my temperature sensor far from heater to get perfect chamber temperature readings,

Problem is heater going to fault, stating temperature raise is too low, 0.1deg/sec

How can I overcome this issue,

I tried PID tuning but it was taking 2 hours to reach phase 3 (measuring) , and didn't complete the tuning.

Any guidance please -

RE: peltier cooler with duet3 6hcposted in General Discussion

@Phaedrux https://robu.in/product/xd-1037-dc12v-60w-semiconductor-refrigeration-sheet-refrigerator-diy-refrigeration-plate-low-power-radiator-system/?gad_source=1&gclid=CjwKCAjwy8i0BhAkEiwAdFaeGPngI6QUG2MbtXkZJg9Zr10fg__W5pp7QXcpx8d4QRaPuV4eEgxCmhoCZ1MQAvD_BwE

Product Name

Semiconductor Refrigeration PlateModel

XD-1037Power Supply Voltage

DC12VEnergy consumption

60WShipping Weight 0.4 kg

Shipping Dimensions 12 × 8 × 6 cm -

peltier cooler with duet3 6hcposted in General Discussion

I want to have a cooling head for a paste extrusion,

Which need 4 -10 deg c, I want to use Thermo electric cooler, how to integrate?

Do duet3d boards support this?