After the BL Touch pin ways damaged and replaced, the sensor flashes red and says it is triggered. Probe self test retracts and deploys pin but then just flashes red.

Thanks in advance

Posts made by damaged_goods

-

original Bl touch always triggeredposted in Third-party add-ons

-

Code for pause and rehome x and y after each layerposted in Tuning and tweaking

Hey All. Little things on my very big homemade printer can cause my axis to shift slightly after putting down a layer. Is there a way to place a command in the config to get the machine to automatically pause and rehome X and y axis and restart?

-

RE: out 7 always onposted in General Discussion

@T3P3Tony I switched it to Out9 and it works fine. Go figure.

-

RE: out 7 always onposted in General Discussion

@Phaedrux I switched it to Out9 and it works fine. Go figure.

-

RE: out 7 always onposted in General Discussion

@Phaedrux I'm going to try switching it to out6 and see it that works.

-

RE: out 7 always onposted in General Discussion

@T3P3Tony

I have had the board for a couple of years and I think I have always had an issue will this fan control. I always assumed it was a coding issue, so I added it to the list Just getting around to trying to fix it now.

Just getting around to trying to fix it now. -

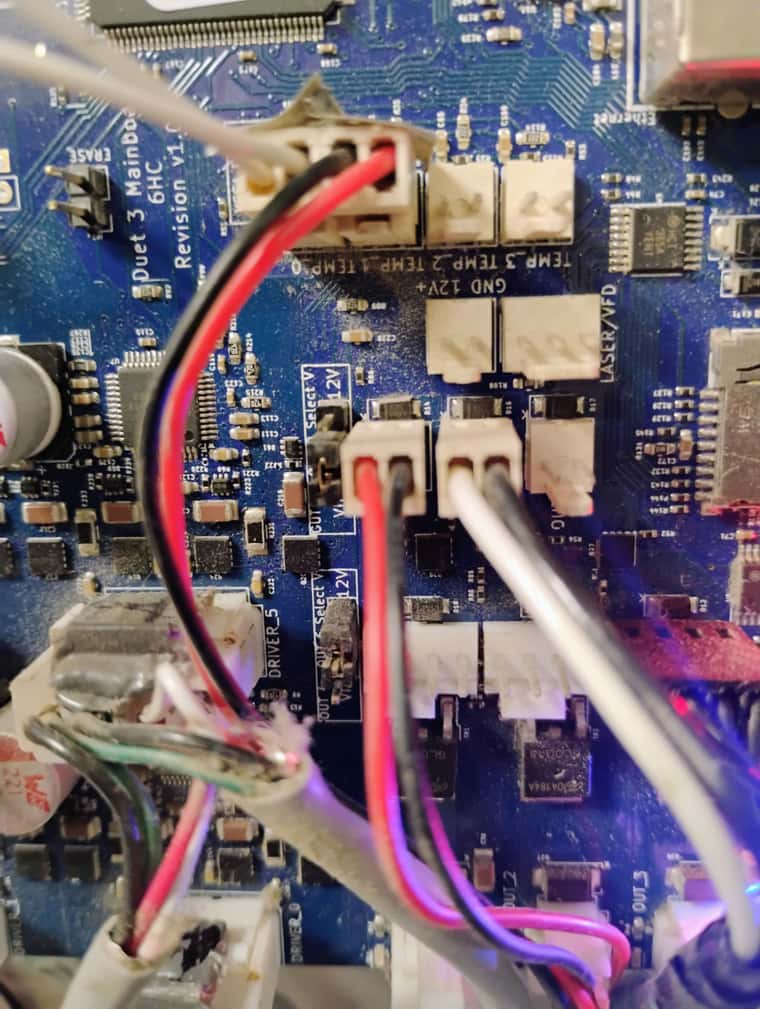

out 7 always onposted in General Discussion

I have tried S0 and S1 but the fan is always on max. Out put 8 is using the same code but works perfectly.

Thanks in advance,

Dave

Board: Duet 3 MB6HC (MB6HC)

Firmware: RepRapFirmware for Duet 3 MB6HC 3.4.5

M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency

M106 P0 C"heatblock fan" S1 H-1 -

RE: Concentric gapsposted in General Discussion

@o_lampe Good thought but no the first layer appears clean.

-

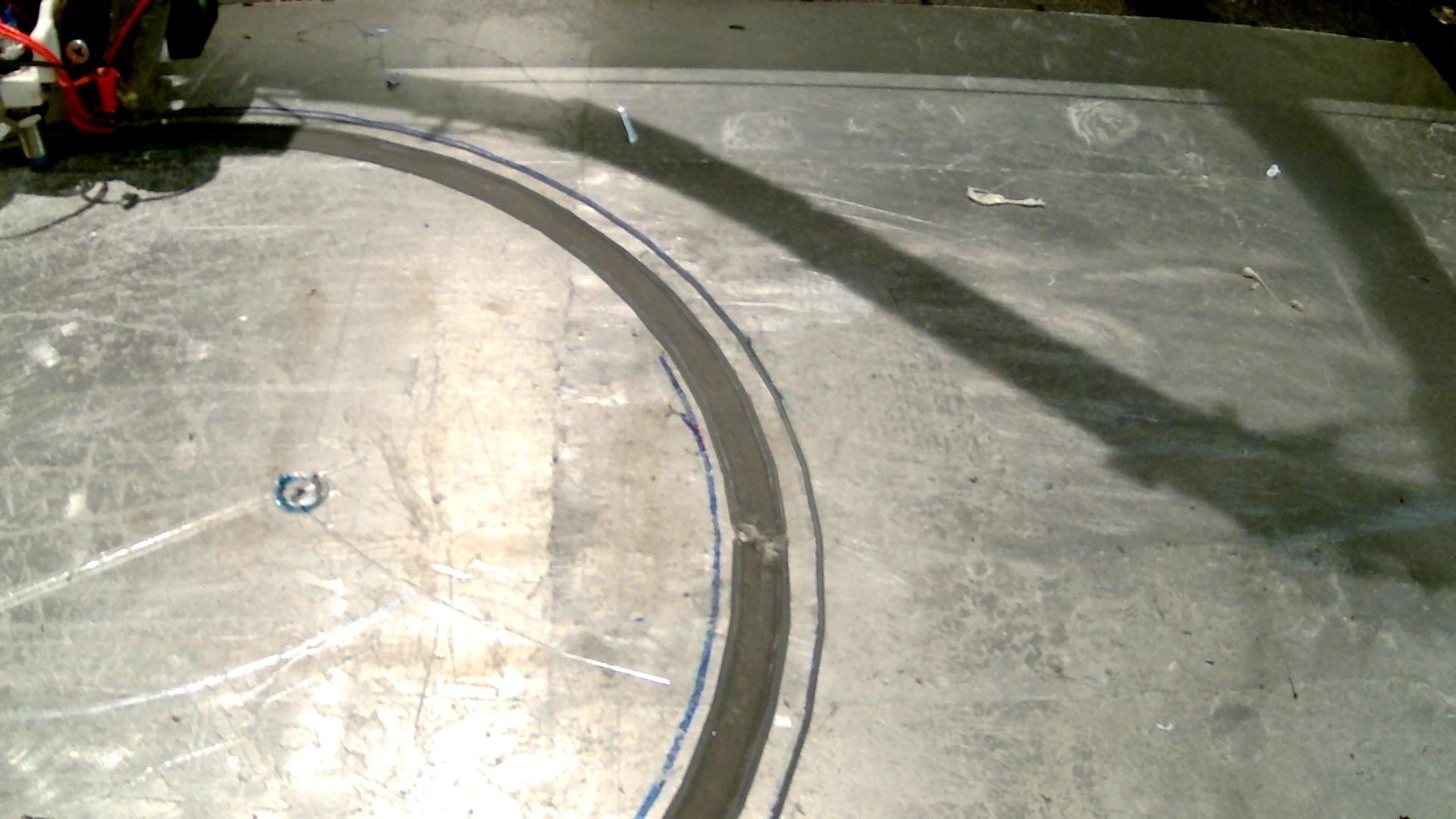

Concentric gapsposted in General Discussion

Any ideas as to why I am getting these gaps in my concentric infill? -

RE: A2 SD card WOW!posted in General Discussion

@dc42 stand alone. My file uploads went from taking several minutes to being instantaneous. Huge difference in speed. It remains to be seen how this will influence prints but I am enthused by this change.

-

A2 SD card WOW!posted in General Discussion

I just replaced the micro SD that came with my board with a A2 rated 32gig and Wow what a difference. So so much faster!!!

Given that my printer is huge 1.5m x1.5m x 2.0m and the Gcode is huge it has to make a big difference. -

RE: 2nd extruder stepper to pull filament off 5 kg reelposted in Duet Hardware and wiring

@deckingman working perfectly. Thank you.

-

RE: 2nd extruder stepper to pull filament off 5 kg reelposted in Duet Hardware and wiring

@deckingman said in 2nd extruder stepper to pull filament off 5 kg reel:

@damaged_goods said in 2nd extruder stepper to pull filament off 5 kg reel:

I am guessing that I can fine tune matching speeds by altering the ratio?

You could but it's a bit course. Obviously both extruders need to feed the same amount otherwise they'll be fighting against each other. You need to keep the hot end extruder the same and make any changes to the one that pulls off the reel (let's call it the "feeder"). So it's important that the steps per mm for each extruder is correct but if you need to make fine adjustments, then tweaking the steps per mm of the "feeder" extruder would give finer adjustment than changing the mixing ratio which will only go in 1% increments. You want to avoid the situation where the hot end extruder is pulling against the "feeder" extruder so it is preferable that the one pulling off the reel over extrudes slightly. So you'd want to reduce the steps per mm for that one slightly. i.e if 400 steps gave you one mm, and you "told" the firmware that it was 398 steps per mm, then 400 steps would give you (1/398*400 = 1.005mm. Obviously for a very long print, you might end up with quite a long loop of filament between the feeder and the hot end, in which case increase the steps per mm of the feeder slightly.

Edit. What you don't want is the filament between the two extruders being taught.That is why I am adding the second feeder extruder.

Thanks again for your help

-

RE: 2nd extruder stepper to pull filament off 5 kg reelposted in Duet Hardware and wiring

@deckingman said in 2nd extruder stepper to pull filament off 5 kg reel:

Now that I'm in front of my PC, I can give you a more comprehensive answer in case you haven't already figured it out. So define your tool (s) to use both extruders - e.g. M563 P0 S"Tool 0" D0:1 H1. Note that the extruder drives are referred to in the order that they were created in M584. So in your case, the extruder connected to the main board, drive 4 (0.4) becomes D0 in the M563 command, and the second extruder (0.3) is referred to as D1.

Then after M563, you need M567 to set the mixing ratio. As this is a "push-pull" arrangement we need to set both extruders to use 100%. So the command you need is M567 P0 E1.00:1.00 (where P0 refers to tool 0).Thank you sir. I was just about to get into it. Your knowledge is greatly appreciated. It always makes me nervous when I start making somewhat blind changes to the config. It's been working so well!

I am guessing that I can fine tune matching speeds by altering the ratio? -

RE: 2nd extruder stepper to pull filament off 5 kg reelposted in Duet Hardware and wiring

'tools" that is what I was missing

-

2nd extruder stepper to pull filament off 5 kg reelposted in Duet Hardware and wiring

I want to add 2nd extruder stepper, on a separate driver, to pull filament off 5 kg reel. Should be simple right?

M584 X0.0 Y0.5 Z0.1:0.2 E0.4:0.3

Driver 3 is the added stepper. which ever motor I list first works the other does not turn.

I initially tried running both motors (slightly different) off the same driver but the speeds differed. I thought using a spare driver would work as well.

Any ideas? -

Can I edit Gcode in DWCposted in General Discussion

Hi all. I need to edit a very very large file to recover a failed print but the "edit file" is greyed out in DWC. Can it be done? Any suggestions? Ponterface struggles.

-

Cold bed adhesiveposted in General Discussion

I built a very large printer with a heated bed that warped ridiculously with heat. I eventually broke it trying to level it so I started printing on the cold surface.

Long story short, I discussed the issue with my wife, a quilter. She suggested a basting spray she uses for sticking fabric together.

It worked amazing!!!

Stayed sticky through multiple prints.