Hi Guys,

This is following on from the end of my thread "Cast Toolplate Bed Progress ?", the last 8 posts within.

https://forum.duet3d.com/topic/34461/cast-toolplate-bed-progress/34?_=1704187570604

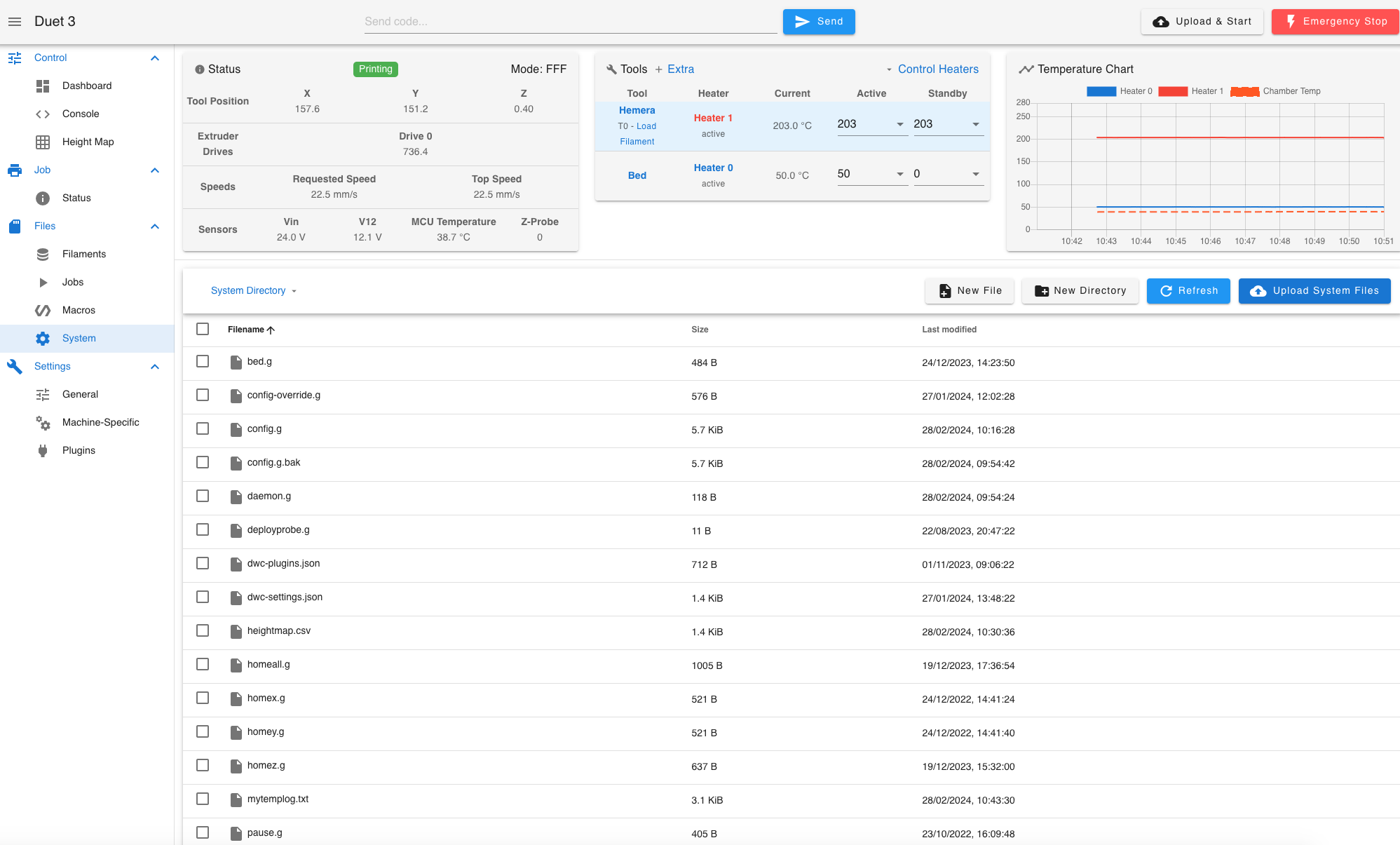

I have a Duet 6HC with a NC Emergency Stop Mushroom type button switch. When I press the emergency stop button, it stops everything as is should, but when I disengage the switch I have to manually click the RESET MACHINE radio button on DWC on my computer screen.

I've tried various methods and combinations using the triggers, but nothing eliminates having to physically click the radio button on my computer screen.

The triggers and the switch have been tested and all function correctly.

I now believe it's something in the actual program in C++;

@Dizzwold said in Cast Toolplate Bed Progress ?:

https://github.com/Duet3D/RepRapFirmware/blob/3.4-dev/src/GCodes/GCodeInput.cpp

src/GCodes/GCodeInput.cpp

From line 144-219 is regarding the M112 command and how it is reset. I think?

Lines 188, 189, 205, 206 prevent a perpetual reset?

@Dizzwold said in Cast Toolplate Bed Progress ?:

RepRapFirmware/src/GCodes/GCodes.cpp

Lines 866-872

Dizzwold.

M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.4.6 (2023-07-21 14:11:38) running on Duet 3 MB6HC v1.01 (standalone mode)

Board ID: 0JD2M-999AL-D25SW-6J9D0-3SD6M-9PY70

Used output buffers: 3 of 40 (13 max)

=== RTOS ===

Static ram: 153252

Dynamic ram: 97472 of which 44 recycled

Never used RAM 99904, free system stack 194 words

Tasks: NETWORK(ready,31.7%,165) ETHERNET(notifyWait,0.0%,567) HEAT(notifyWait,0.0%,321) Move(notifyWait,0.0%,352) CanReceiv(notifyWait,0.0%,798) CanSender(notifyWait,0.0%,335) CanClock(delaying,0.0%,349) TMC(notifyWait,7.5%,90) MAIN(running,60.5%,925) IDLE(ready,0.1%,30), total 100.0%

Owned mutexes:

=== Platform ===

Last reset 00:02:32 ago, cause: power up

Last software reset at 2024-01-11 12:27, reason: User, GCodes spinning, available RAM 99904, slot 2

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Aux0 errors 0,0,0

Step timer max interval 127

MCU temperature: min 23.6, current 35.7, max 35.9

Supply voltage: min 24.1, current 24.2, max 24.2, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.1, current 12.1, max 12.2, under voltage events: 0

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0, mspos 8, reads 2389, writes 14 timeouts 0

Driver 1: standstill, SG min 0, mspos 8, reads 2389, writes 14 timeouts 0

Driver 2: standstill, SG min 0, mspos 8, reads 2389, writes 14 timeouts 0

Driver 3: standstill, SG min 0, mspos 8, reads 2390, writes 14 timeouts 0

Driver 4: standstill, SG min 0, mspos 8, reads 2390, writes 14 timeouts 0

Driver 5: standstill, SG min 0, mspos 8, reads 2393, writes 11 timeouts 0

Date/time: 2024-01-14 09:58:45

Slowest loop: 6.57ms; fastest: 0.05ms

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 25.0MBytes/sec

SD card longest read time 3.5ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 0, maxWait 0ms, bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

Heater 1 is on, I-accum = 0.0

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

SBC is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== CAN ===

Messages queued 1391, received 3058, lost 0, boc 0

Longest wait 3ms for reply type 6053, peak Tx sync delay 177, free buffers 50 (min 49), ts 765/764/0

Tx timeouts 0,0,0,0,0,0

=== Network ===

Slowest loop: 6.55ms; fastest: 0.03ms

Responder states: HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8

= Ethernet =

State: active

Error counts: 0 0 0 0 0 0

Socket states: 2 2 2 2 2 0 0 0

=== Multicast handler ===

Responder is inactive, messages received 0, responses 0```