@fcwilt OK, I will give it a try tomorrow.

My Z home is X=0 Y=20

So I will do a home all

Then the auto-bed level

Then do a G30 P0 X0 Y20 (do I include the Z-99999?) Or just do a G30 X0 Y20?

Then run the mesh analysis?

@fcwilt OK, I will give it a try tomorrow.

My Z home is X=0 Y=20

So I will do a home all

Then the auto-bed level

Then do a G30 P0 X0 Y20 (do I include the Z-99999?) Or just do a G30 X0 Y20?

Then run the mesh analysis?

@fcwilt Hi,

Yes, I have simple contact leaf switches for homing X & Y, and then it uses the BLTouch to home the Z.

And yes, I have triple Z=Screws and steppers for my bed (I'm running a HevORT printer).

My Z Offset in the my system config.g is G31 P500 X36 Y-9 Z4.55 (I'm running a Phaetus Rapido hotend)

This is my home all code.

True Bed leveling code follows

; homeall.g

; replacing all old code, that didn't work

; HOME ALL New 20240515

;home X code

; called to home the X axis

;

G91 ; relative positioning

G1 H2 Z5 F500 ; lift Z relative to current position was F500 is Z speed was 9000

G1 H1 X-420 F3000 ; move quickly to X axis endstop and stop there (first pass)

G1 X5 F3000 ; go back a few mm

G1 H1 X-420 F360 ; move slowly to X axis endstop once more (second pass)

;G1 H2 Z-5 F500 ; lower Z again was 9000

G90 ; absolute positioning

; home Y code

; called to home the Y axis

;

G91 ; relative positioning

;G1 H2 Z5 F500 ; lift Z relative to current position was 9000

G1 H1 Y-420 F3000 ; move quickly to Y axis endstop and stop there (first pass) said 420

G1 Y5 F3000 ; go back a few mm

G1 H1 Y-420 F360 ; move slowly to Y axis endstop once more (second pass) said 420

;G1 H2 Z-5 F500 ; lower Z again was 9000

G90 ; absolute positioning

; home Z code

; called to home the Z axis

;

G91 ; relative positioning

;G1 H2 Z5 F500 ; lift Z relative to current position was F9000

G90 ; absolute positioning

;G1 X0 Y20 F3000 ; go to first probe point was X30 and Y55

G30 ; home Z by probing the bed

G90 ; Me adding to see if this fixes some of my problems

Code for the true bed leveling. It tests 4 points on the bed.

;Changed this to a triple set up, so I don't have to do it manually

G30 P0 X36 Y11 Z-99999 ; probe near a leadscrew - new from Oliver X was setto 29, but banged

G30 P1 X36 Y376 Z-99999 ; probe near a leadscrew

G30 P2 X396 Y376 Z-99999 ; probe near a leadscrew

G30 P3 X396 Y11 Z-99999 S3; probe near a leadscrew

@fcwilt Oh, and my z homing uses my BLTouch, so that should deal with this? Yes?

But that homing point is also in the front left corner.

EDIT: OK, I found it in the manual.

Am I still doing something procedurally wrong? I heat up the nozzle and bed for a good while. Extrude some filament, and then retract a bit, so it doesn't ooze.

I initially do a home all. Then I will run a True Bed Leveling (G32). After that I ran the mesh compensation.

I'm thinking I should probably do another home of Z, as my bed leveling's last measurement is in the front right hand corner of the bed. Where the 1st measurement of the Mesh is in the front left.

Am I on the right track?

Thanks.

Michael

Well, there ya go, I need to do Z=0 Datum. Where should I do it?

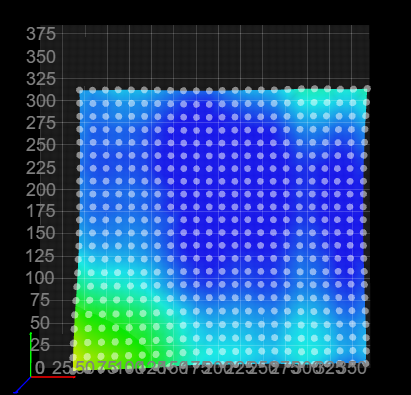

This is the Stats on the mesh reading.

Number of points: 506

Probe area: 1039.5 cm²

Maximum deviations: -0.303 / 0.109 mm

Mean error: -0.189 mm

RMS error: 0.078 mm

Is that what you are looking for.

And would you mind pointing me to where to look in the RTFM for setting the Z=0 datum.

Thanks.

Michael

Hi,

I did a big multi-point height map. As you can see my bed's in pretty good shape, except for the front left corner. I've been lucky, as most of the time, I've not needed the entire bed to print, but need it this time, and was planning on printing with Mesh Compensation for the 1st time.

When loading the saved height map, it seems to get worse, where the left front, the nozzle is mashed to the plate, and can't extrude worth a lick.

The rest looks fine. Am I doing something wrong?

I'm assuming that most of the bed is blue due to the Z offset? Do I need to change a different Z-Offset for mesh?

@droftarts Hi,

I'm just an idiot. I didn't realize that while the printer is paused, I could manually extrude filament.

I thought since it was paused, I wouldn't have access to any of the normal controls.

I'm good for now. The pause and resume are working as I would like them to.

But I will still look into the Filament Error to see what it's capable of doing.

Thanks.

Michael

Hi,

I finally added a filament sensor, which seems to be working fine.

When the out of filament sensor trips, the pause.g seems to work fine. And it looks like it retracts 10mm of filament with the pause.

pause.g (made no changes)

M83

G1 E-10 F3600

G91

G1 Z5 F360

G90

G1 X0 Y0 F6000

But the resume.g moved the head back to position, and then does a 10mm filament push before restarting the print.

G1 R1 X0 Y0 Z5 F6000

G1 R1 X0 Y0

M83

G1 E10 F3600

What I'd like to do is 1st push some filament through the nozzle, and have it wait, so I can clean it with my toothbrush, and then resume the print. But the following doesn't work.

G1 E10 F3600

G4 S010

G1 R1 X0 Y0 Z5 F6000

G1 R1 X0 Y0

M83

What am I doing wrong?

Thanks.

Just a word of warning.

I'm used to the red stripe on a ribbon connector annotating pin 1.

Whelp, I got my DUET3D Accelerometer in the mail, and went to hook it up, and came to find the ribbon is installed on the connectors flipped.

Since you can only plug the cable into the Accelerometer one way, you need to be careful, and install the connector on the Duet3D M/B with pin 1 flipped to pin 10.

@dc42 Thank you very much. That's exactly what I was looking for.

@dc42 Hi, thanks for the feedback. Yes, the bed goes down, which I would agree would be the same as the head going up.

But what 2 digit code would I use in the M955 command.

@guitartoys I think I sorted it.

I61?

Hi,

OK, I'm just an idiot.

I'm finally getting ready to do some input shaping, and trying to sort out the orientation for the Duet3D Accelerometer.

I've got a HevORT with a HexTrudOrt with a Phaetus Dragon hotend. Along with a Berd air cooler on a CPAP fan.

My BLTouch is mounted close to the right.

The best way for me to leave both the BLTouch and the Berd Air cooler in place is to orient the Duet3D Accelerometer where the connector is down and to the front. (I could have the connector side up, but would need some washers so the chips on the board don't hit the heat block).

X+ goes to the right, Y+ goes back (away), and Z+ goes down.

What would the 2 digit code be? Or is this orientation not supported?

Thanks.

Michael

@Exerqtor Thanks. I'll read through the change log.

Hi,

i ran updates and upgrades the other day, and while the printer seems to be printing fine, my macros to turn my LED strips on and off no longer seem to be working.

Is there something I should be doing to remedy this after the update?

Thanks.

Michael

Hi,

Since the update, I've lost a couple of things and also want to know if there are abilities to tweak.

I'm using a 10" display in portrait mode (as it fits the gap in my printer frame best)

The Send Code box and button do not appear

The menu makes you click it to individually drop down the submenu. It used to just be fully expanded it. Can I set it back that way?

On the earlier version, essentially the top of the dashboard would be displayed on the Console and Status pages. Is there a way to get that back?

Thanks

Michael

@phaedrux friend, you just gave me exactly what I needed. It's the M558 command. I can totally sort it out from there.

Thanks.

Michael

Hi,

I've got a HeVORT, with a 3 Z Axis. It's working fine. But due to the size and weight of the bed (440 x 440) MIC Al plate and 6mm glass, I slowed the z down some

When I run auto-level, it works fine, but drops the Z down 15mm then does the level touch (BLTouch).

Is there a way I can instead just have it drop 5mm instead of 15mm, just so it finishes quicker.

G30 P0 X30.1 Y88.5 Z-99999 ; probe near a leadscrew

G30 P1 X30.1 Y425.5 Z-99999 ; probe near a leadscrew

G30 P2 X380.1 Y425.5 Z-99999 ; probe near a leadscrew

G30 P3 X380.1 Y88.5 Z-99999 S3; probe near a leadscrew

Thanks.

Michael

OK, it looks like a 693ZZ

Sorry for the bother.

Hi, I'm looking to add a roller switch to the sensor, and would like to put a similar bearing as the idler along with it.

The Idler bearing fits a 3mm screw, is 4mm tall and 8mm in diameter.

I don't know how to look this up.

Help would be appreciated.

Thanks

Michael