@Phaedrux I had a blonde moment, I can't use a normal 2pin fan can I?

I need a 3+ wire fan right? (sorry never actually used PWM function of fans before)

My artillery sidewinder specs:

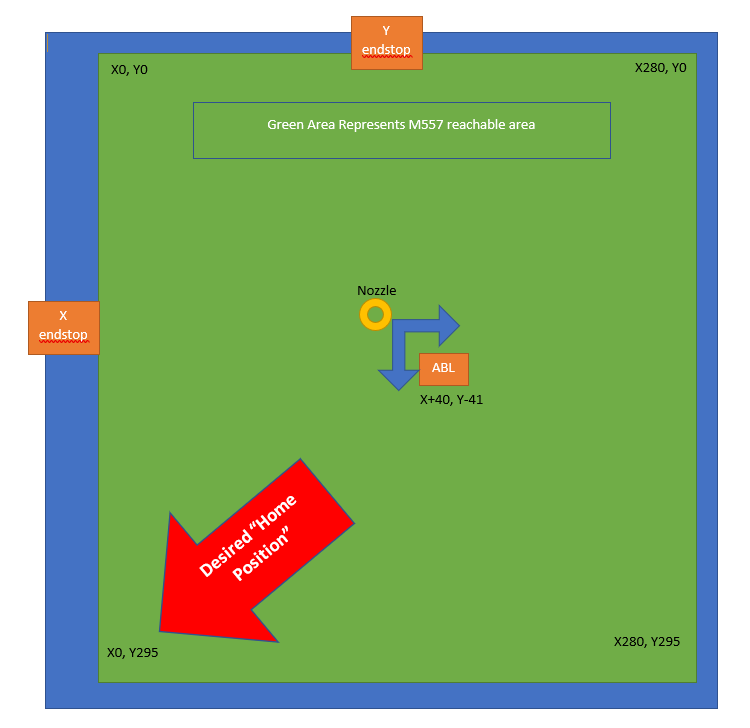

Xaxis: homes at 0, left side (Panasonic GL8H optical NPN NC sensor)

Yaxis: homes at back, but 0 is actually at the front (Panasonic GL8H optical NPN NC sensor)

Z = Inductive ABL probe (Panasonic GXHL15A NPN NC sensor)

Lastly, here is my RRFconfigurator custom config.g for RRF3.1:

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Aug 15 2020 15:29:14 GMT-0400 (EDT)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Sidewinder X1 RRF3" ; set printer name

; Network

M552 S0

M552 S1 P192.168.1.50 ; Assign fixed IP address

M553 P255.255.255.0 ; Assign Netmask to match my network

M554 P192.168.1.1 ; Assign Gateway IP address to match network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S0 ; physical drive 1 goes backwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S0 ; physical drive 3 goes backwards

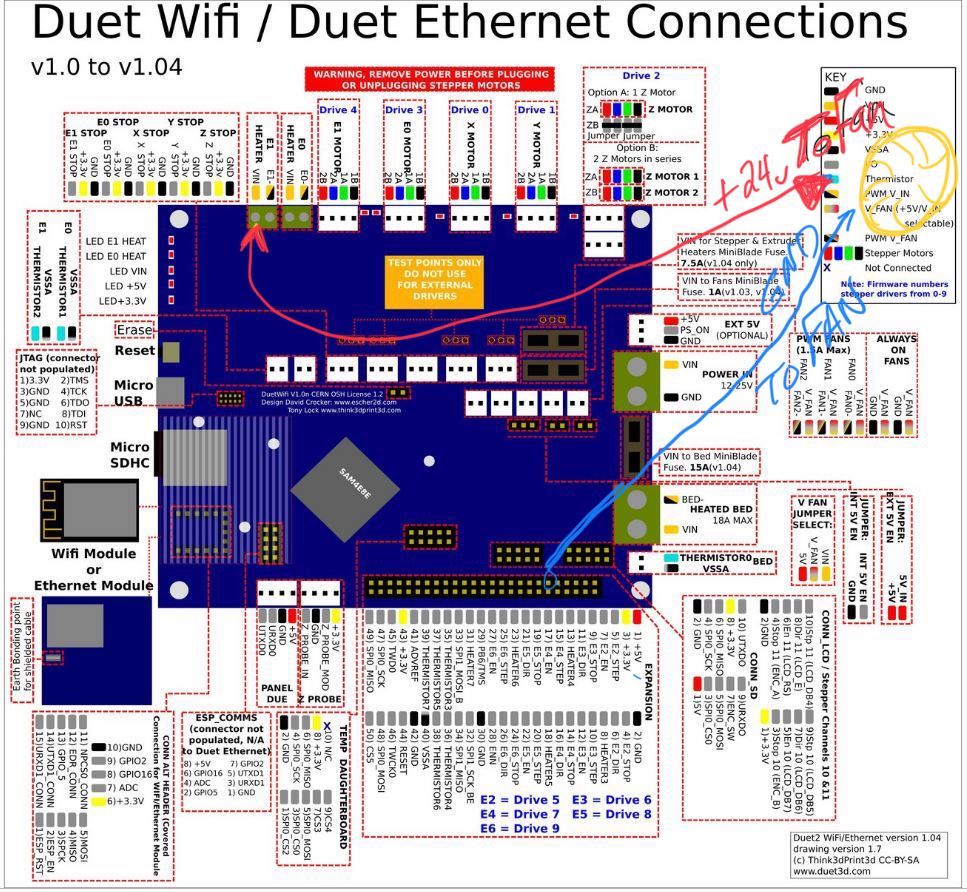

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E415.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E1200.00 ; set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z1500.00 E3000.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E166.67 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y340 Z400 S0 ; set axis maxima

; Endstops

M574 X2 S1 P"xstop" ; configure active-high endstop for high end on X via pin xstop

M574 Y2 S1 P"ystop" ; configure active-high endstop for high end on Y via pin ystop

M574 Z2 S2 ; configure Z-probe endstop for high end on Z

; Z-Probe

M558 P1 C"zprobe.in" H5 F600 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P1000 X40 Y-41 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X45:295 Y10:280 S40 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S130 ; set temperature limit for heater 0 to 130C

M308 S1 P"e0temp" Y"thermistor" T500000 B4723 C1.19622e-7 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 C"Layer Fan 1" S0 H-1 ; set fan 0 name and value. Thermostatic control is turned off

M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency

M106 P1 C"HE Fan 2" S1 H1 T45 ; set fan 1 name and value. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

and for reference, here is the back up of the RRF2.03. config.g that I made just before updating to RRF3 this afternoon:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.1.8 on Sat Apr 11 2020 14:47:32 GMT-0400 (Eastern Daylight Time)

; Revised by Jake Allen on 4.18.2020 @ 10:30am EST

;-----General preferences-----------------------------------------------------------------------------------------------------------------

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Sidewinder X1" ; set printer name

;-----Network----------------------------------------------------------------------------------------------------------------------------

M552 S0

;M552 S1 P192.168.1.50 ; Assign fixed IP address

M553 P255.255.255.0 ; Assign Netmask to match my network

M554 P192.168.1.1 ; Assign Gateway IP address to match network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

;-----Drives-----------------------------------------------------------------------------------------------------------------------------

M569 P0 S0 D2 ; (X-Axis) drive 0 goes forwards (Jake wrong config M569 P0 S1)

M569 P1 S1 D2 ; (Y-Axis) drive 1 goes forwards

M569 P2 S1 D2 ; (Z-Axis) drive 2 goes forwards

M569 P3 S1 D2 ; (Extruder) drive 3 goes backward with Bondtech (titan = S0, Bondtech = S1)

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure micro-stepping with interpolation

M92 X80.12 Y80.12 Z399.78 E415.0 ; set steps per mm (from Jake's Marlin Setup) (titan=446mm)

M566 X800.00 Y980.00 Z60.00 E2500.00 ; set maximum instantaneous speed changes (mm/min) --> E180 to E2500, Z12 to Z60

M203 X9000.00 Y9000.00 Z1500.00 E3000.00 ; set maximum speeds (mm/min) --> X&Y from 6000 (100mm/s) to 9000 (150mm/s)

M201 X800.00 Y800.00 Z400.00 E10000.00 ; set accelerations (mm/s^2) E10000

M906 X800 Y800 Z800 E800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

;-----Axis Limits------------------------------------------------------------------------------------------------------------------------

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X300 Y340 Z400 S0 ; set axis maxima (Changed Y from 300 to 345 to compensate for offset)

;-----Endstops---------------------------------------------------------------------------------------------------------------------------

M574 X1 Y1 S0 ; set active low and disabled endstops (To enable Z-endstop add "Z1 or Z2" after y

M574 Z1 S2 ; Define Z to use probe. S2=Home to min

;-----Z-Probe (BLtouch)------------------------------------------------------------------------------------------------------------------

M307 H3 A-1 C-1 D-1 ; (Duet3d method) disable Heater7 to free up PWM channel 5 on Duex board for BLTouch

M558 P5 H5 F600 A1 I1 ; GLH8 EndstopABL, Mode P=5, StartProbeH=5mm, Speed=300mm/min, #probes A=3, Invert signal for Endstop I=1

;BLTOUCH; M558 P9 H5 F100 T9000 ; (Duet3D method) P=Select Z-probe mode=9 BLtouch. H=DiveHeight abv bed(mm), F=Speed bed moves, T=TravelSpeed btwn pts

G31 P25 X40 Y-41 Z1.385 ; P=Z probe trigger value,X&Y=offset mount relative to nozzle (mm), Z=trigger height 1.84

;(4020 Mosquito J&L Mount + HL15 Zoff=0.7mm, x=40, y=-41)

;(M18 probe,z=1.85mm, x=40, y=-50)

;Stock z-end=0.58

; Change P500 to P25 and X&Y=0 to X=40 & Y=-38 for probe offset vs. nozzle (3DChanh X58 Y-36)

M557 X45:295 Y10:280 S40 ; define mesh grid (S20 = 143 points, S45 = 36pts) (Prev: M557 X15:285 Y15:285)

; Change X0:225 Y45:300 S45 to--> M557 X60:300 Y0:260 S20, S20=156pts, try S24 & S40 =100 & 36pts, Previously S=30

;-----Heaters----------------------------------------------------------------------------------------------------------------------------

M140 H0 ; remap heated bed to heater 1

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; set Bed thermistor + ADC parameters for heater 0

M143 H0 S125 ; set temperature limit for heater 0 to 125C

;M305 P1 T100000 B4138 R4700 ;104GT E3D thermistor set thermistor + ADC parameters for heater 1

M305 P1 T500000 B4723 C1.196220e-7 H20 ; Slice Engr 450°C thermistor Set thermistor +ADC parameters for H1

M143 H1 S320 ; set temperature limit for heater 1 to 300C

;-----Fans--------------------------------------------------------------------------------------------------------------------------------

M106 P1 S0 H-1 C"Layer_Fan" F500 ; Part Cool Layer Fan (8.14.20 blew Mosfets, some cntl Fan1 port so remapped)

;M106 P1 S1 H1 T45 C"Heatsink_Fan" F500 ; Hotend Heatsink Fan

;M106 P2 S0.75 H0 T45 C"BoardCool" F500 ; Ducted 4020 DuetBoard Cooling Fan, Bed=45c turn on fan 75%

;-----Tools-------------------------------------------------------------------------------------------------------------------------------

M563 P0 S"HOTEND" D0 H1 F1 ; define tool 0 (8.14.20 change from F0 to F1 bc of blown mosfet remap)

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

;-----Miscellaneous-----------------------------------------------------------------------------------------------------------------------

M501 ; load saved parameters from non-volatile memory

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss

T0 ; select first tool

]

]