@Electriceye looking at your picture the input wires on the SSR from the duet are reversed you may want to try reversing the polarity,

Best posts made by jumpedwithbothfeet

-

RE: Dead SSR or Bed Heater?posted in Duet Hardware and wiring

-

RE: Entry level Resin Printer Adviceposted in General Discussion

@cncmodeller I have the CL-60 it is very easy to use, literally press play

I also have the wash and cure station which also works well. some notes to consider however -

I also have the wash and cure station which also works well. some notes to consider however -Pro`s -

easy to print

easy to setup

lovely detailed prints and I mean really nice compared to FDMCons -

IPA is super expensive (around £20 in the UK for 5 litres and you will go through it!)

Resin again expensive and you need choose the right resin for the job in hand, the basic Elegoo stuff I've used it very brittle.

Tissue paper and Gloves lots of them!

build volume is poor but my other printer is a 370mm Voron so that might taint it a bit

Clean up can be a pain even with a wash and cure station if you don't have a lot of space to work in.By far the worst part I've found so far is slicing the file, placing the supports choosing the right ones etc is very time consuming and laborious, automatic supports pick the wrong places, add to many or not enough = failed print or a pain to clean up, I'm using Lychee slicer BTW the free version, I cant comment on the paid version.

Going forward I will be using water washable resin to mitigate the IPA price, I have a slight regret in going resin as I didn't fully appreciate the amount of work and cost in using it, but if you have the space, time and money and a specific use for it then the printer is fantastic and well constructed.

I realise what I've written is probably quite negative regarding Resin printing but these are things I wish I had paid more attention to before buying!

-

RE: Duet3 mini voron gantry level problemposted in General Discussion

@jamaicarasta it might be the format displayed and also possibly irrelevant but do you have the bed.g info inside the config.g file?

@jay_s_uk thanks for the link I`ve not got my head around conditional gcode yet but I'll just give it ago

-

RE: Dudes about fansposted in General Discussion

@peirof not sure what board you have but I have board fans running on the MCU temp -

M308 S2 P"mcu-temp" Y"mcu-temp" A"mcu-temp" ; configure sensor 2 as thermistor on pin temp2

M950 F2 C"out9" Q500 ; create fan 2 on pin out.2 and set its frequency (CPU fan)

M106 P2 H2 T40 C"CPU fan" ; set fan 2 value. Thermostatic control is turned on -

RE: Hotend heater does not show up in DWCposted in Duet Web Control

@foesi have you mapped the tool in config.g using M563?

-

RE: Show me your duet 3 enclosures!posted in Duet Hardware and wiring

Finally posted my enclosure on

Thingiverse, I’ll be making further refinements but it’s mostly there, I’m really happy how the logo came out, any suggestions I’m happy to hear them

https://www.thingiverse.com/thing:4307535#edit I have unfortunately had to close my account on thingiverse due to the recent hacking etc I’ll attach the latest STLs to this post soon for those who want them

-

RE: Reprap firmware with cnc... what free cam software?posted in CNC

@3dpmicro I don't mind paying a price as I understand a lot of work goes into designing the software, what I do have is a distaste for is monthly/yearly subscriptions which I personally couldn't justify investing in, I`m sure given time there will be more options as I'm sure there is a growing demand/interest in 5 axis cams/slicers for hobbyists, till then like you say, 3+2 works with a little work

-

RE: Help with new custom printer - Prints have ringing around themposted in General Discussion

@mrawesome987 I'm no way qualified to answer that to be honest, but I did run a very similar set up (without the belt) I didn't have any issues in that regard, I have had the same problem you have though but with 3 lead screws and that was because I hadn`t constrained my bed well enough.

Are your lead screws bent when not attached to the machine? i.e roll them on a flat surface and watch for wobble if they are good check for alignment issues on your printer.

-

RE: Z axis calibration issueposted in Tuning and tweaking

@Phaedrux, @PaulHew , I think I have found out what the issue is or issues! The first was the sensor height after it was moved further up, the nozzle will now home correctly and the correct distance to the bed!

The other issue which I’m sure contributed to both the z cal and my board locking up was I’m sorry to say bad workmanship, after we spoke Paul I started shift stuff around for the standalone, thats when I saw the Z axis driver plug pins where not sitting in line it’s plugged it fine when you pull the plug they are all aligned, all have continuity with no shorts but some solder got further into the pin causing a poor connection!

I’ve now redone the plug and so far so good, I’ve Carried out G32 and will attempt a print shortly to see if there is any difference.

Either way I can’t thank you both enough for your help, feel like I might actually now get somewhere!

I’ll update the thread post print!

Jim

-

RE: Show me your duet 3 enclosures!posted in Duet Hardware and wiring

As mentioned in the above post I've quit thingiverse due to the latest spam/hack issues they have had, I've attached the STL's and wings3d files for the Modular Duet 3 case for anyone who wishes to use them, if there is a mod you would like let me know

Duet3 board case (power cable slot) V4 BL.stl

Duet3 board case (power cable slot) V4 BL board spin.stl

RPi4 side plate V2.stl

RPI3B+ side plate V2.stl

RPI3B+ side plate V2 mirrored.stl

Fan side plate.stl

Deep Fan side plate V3 40x40x20mm.stl

Deep Fan side plate V2.stl

blank side plate.stl

blank side plate upper.stl

blank side plate lower.stl

AXIS wiring side plate.stl

AXIS wiring side plate with spiggot.stl

AXIS wiring side plate with LRG spiggot PWR.stl

top V2.2 offset 80mm FAN NO guard Mirrored.stl

Duet3 board case top V2.2.stl

Duet3 board case top V2.2 80mm FAN with guard.stl

Duet3 board case top V2.2 80mm FAN NO guard.stlRegards Jim

Edit: formatting

-

RE: Deckingman's passingposted in Off Topic

Sorry to hear this, I’ve read a lot of Ian’s posts and watched his YouTube videos, a lot of good info. RIP

-

RE: Help with new custom printer - Prints have ringing around themposted in General Discussion

@mrawesome987 I noticed your using a flex coupling on at least one of your z stepper motors, good possibility that z belt of yours might be pulling the leadscrew out of alignment, worth checking with a print and the belt removed?

-

RE: Issues with IR Probe offsetposted in Tuning and tweaking

@agent0810 @Phaedrux It might be the picture but is the board to high? The quote below is from the installation instructions, worth double checking?

“The bottom edge of the board should be between 1mm and 2mm higher than the tip of the nozzle. This should give you a trigger height between 0.5mm and 1.5mm.”

Regards Jim

-

RE: Hotend stalling during movement and baby stepping issueposted in Duet Hardware and wiring

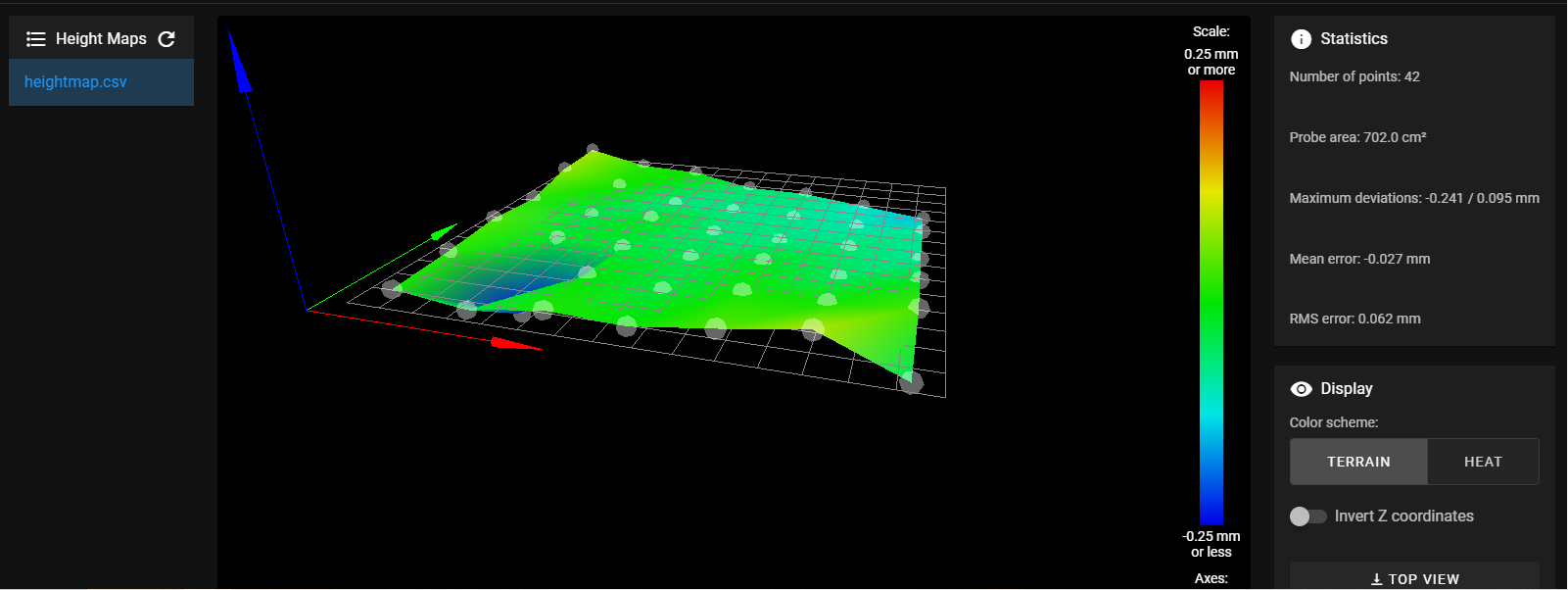

@phaedrux, After multiple attempts with both black and white paper including a comical poor chase the hot end around with the paper, I resorted to using just the bare unpolished aluminium bed, pretty much proof the glass bed is causing the sensor a head ache the two blue areas are chamfered screw holes I believe.

I have ordered some Lokbuild to replace the kapton tape.

Thankyou all for your help and for educating me

-

RE: Printer freezes at start of printposted in Third-party software

@PaulHew I have to say even tho it’s taken over a week to get something printed and that’s mainly down to user induced faults! I still feel like I’ve got out of an escort and jumped into a Ferrari with this board, all I’ve got to do now is learn how to drive

-

RE: sensor irposted in General Discussion

@sgk @oliof, I maybe off base but would it be worth trying the probe in mode 8? this is the way my IR sensor is configured, then use the paper with the bed well out of the way to trigger a response?

-

RE: Print 12 mm over bedposted in Tuning and tweaking

@stubbedk well that explains the trigger height!, apologies if i'm telling you to suck eggs but did you reset G31 to Z0 before you carried out the trigger height calibration?

-

RE: Stepper current - per phase and M906 settingposted in Duet Hardware and wiring

@jhalewood,1.7A and use 80% of that, if your extruder is skipping that maybe a heat related issue and something else to look into!

-

RE: Curious motor issue.posted in Using Duet Controllers

@breed have you checked the phases are connected correctly some steppers need the middle two wires crossed over?