Hi,

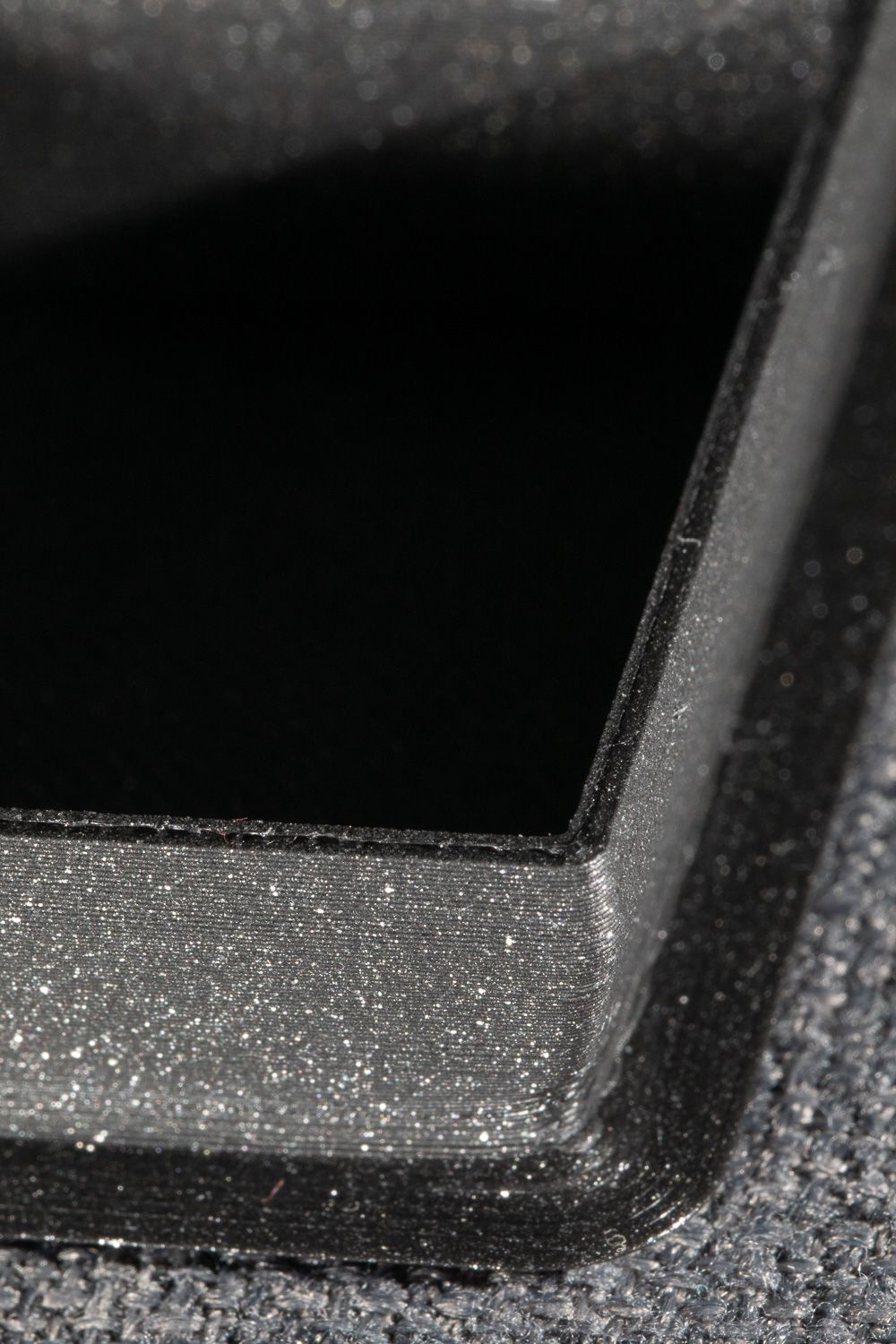

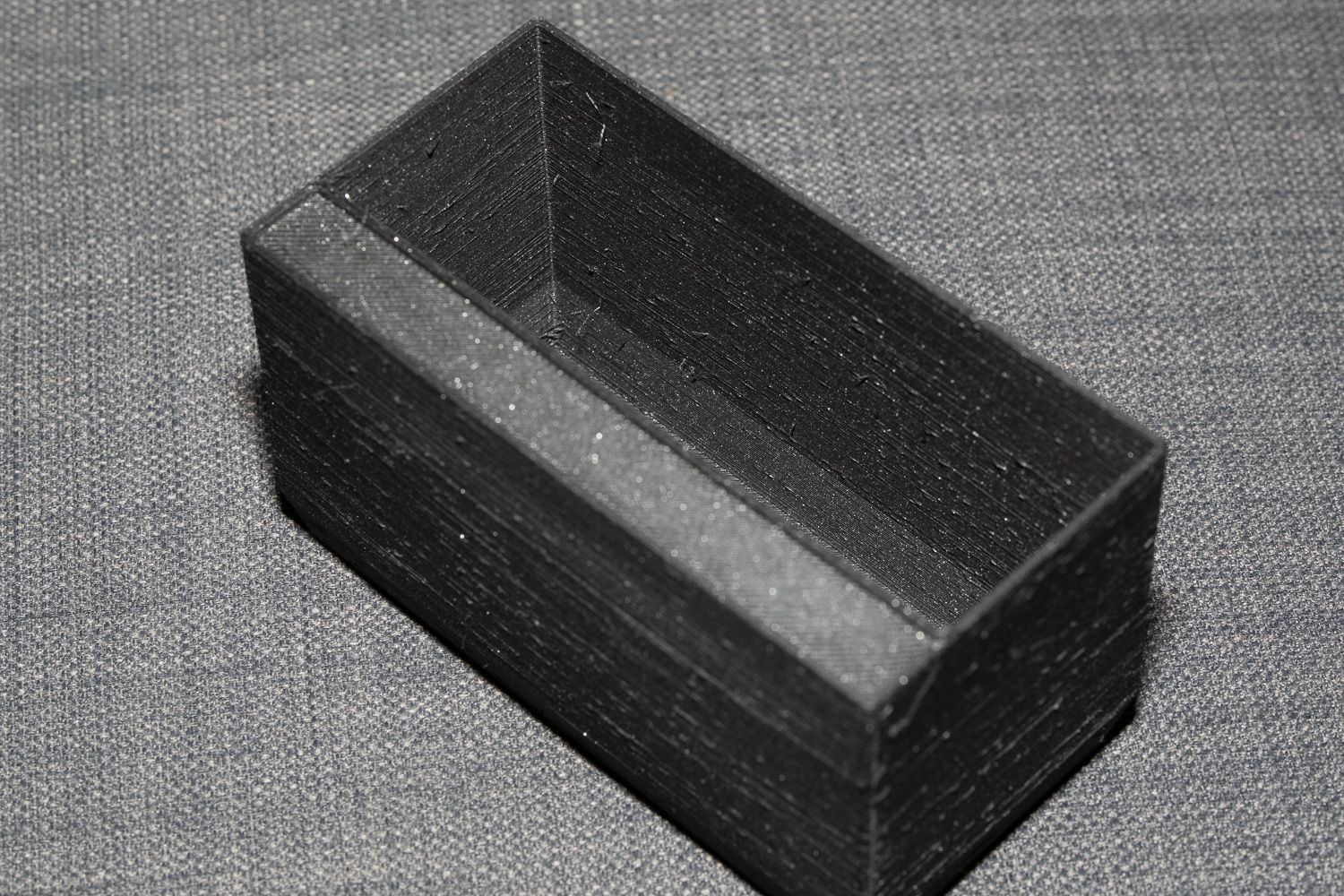

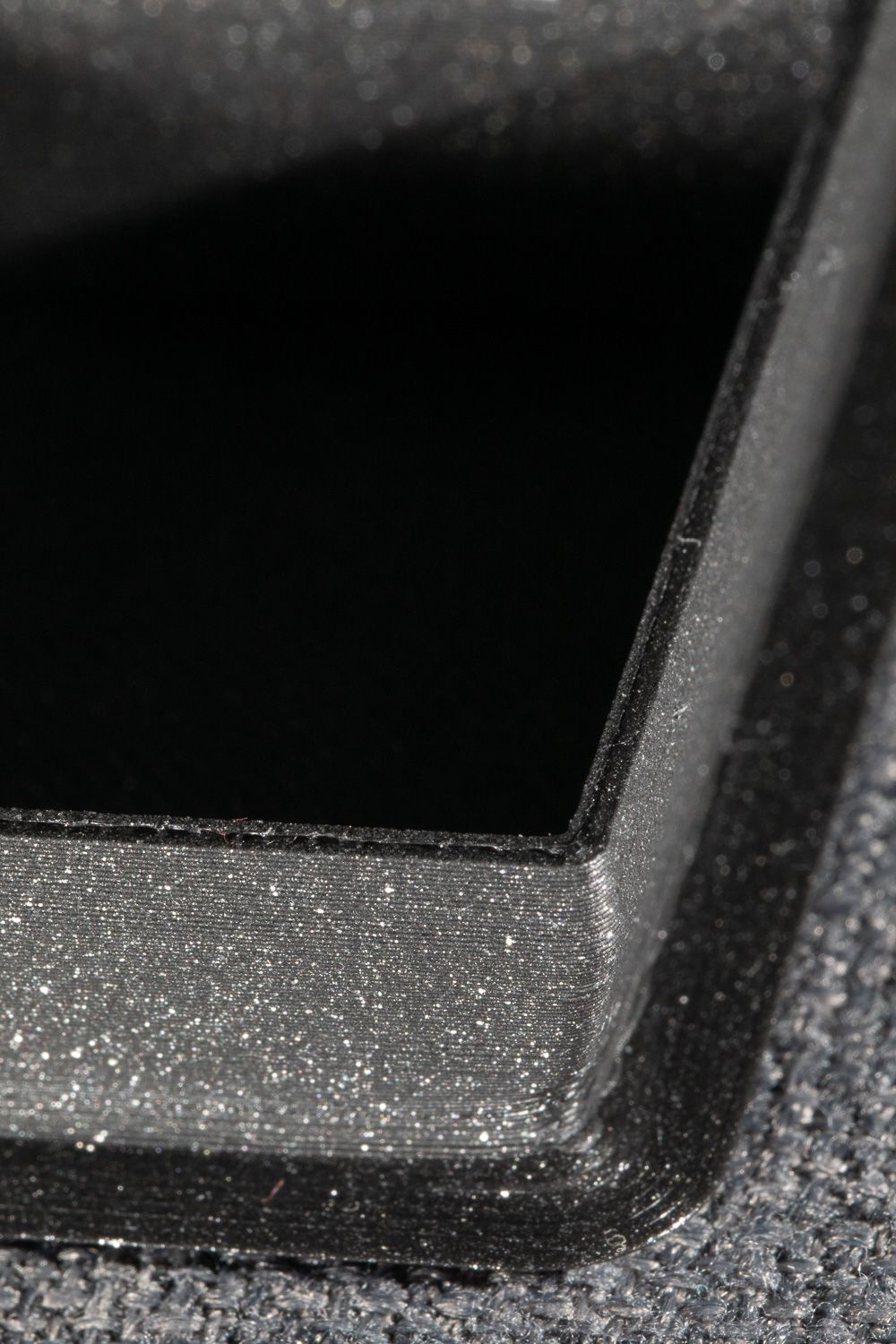

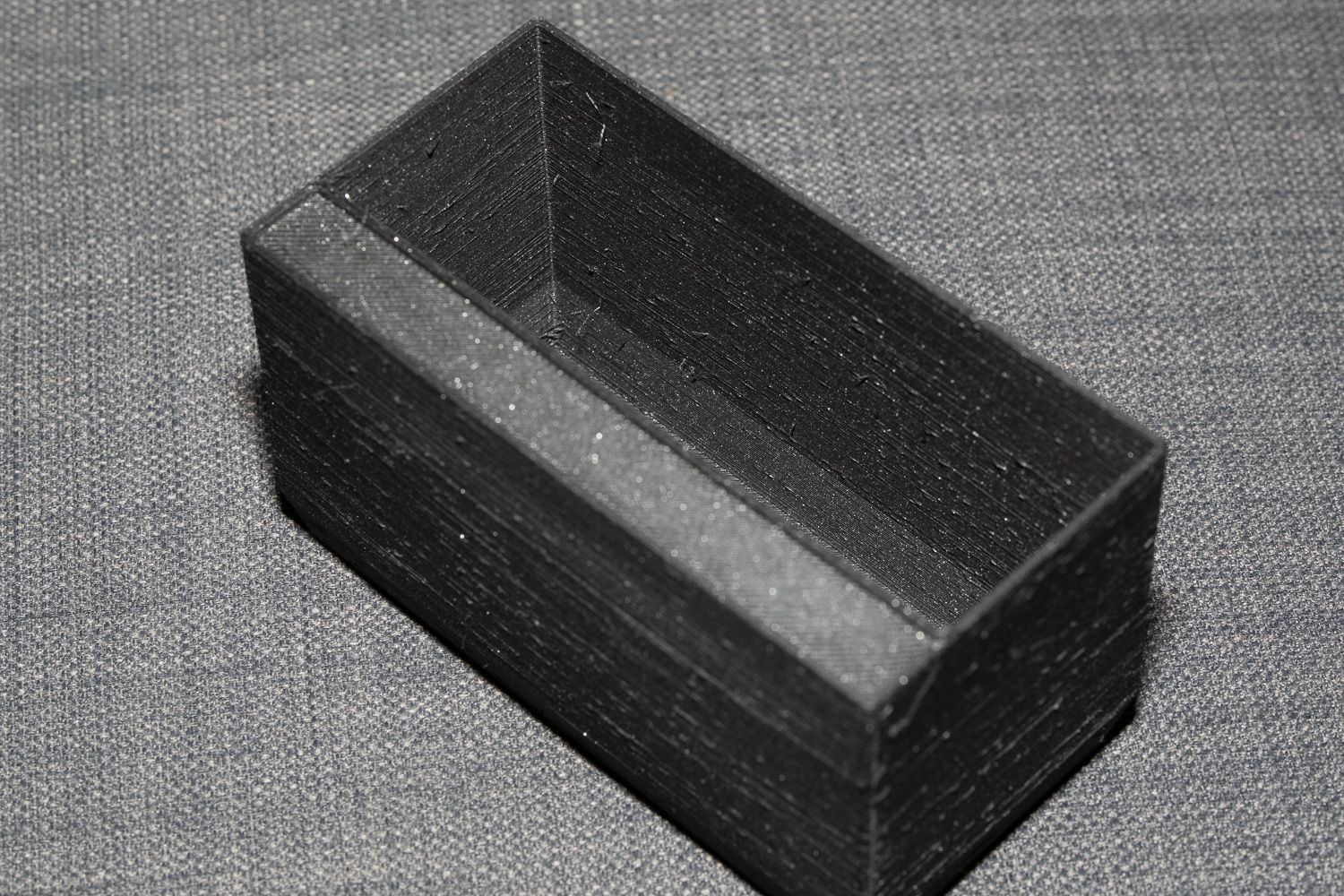

I have a extrusion problem with my big delta printer. It seems that the end or the start (or both) of an extrusion is problematic. My current print project are assortment-boxes for drawers.

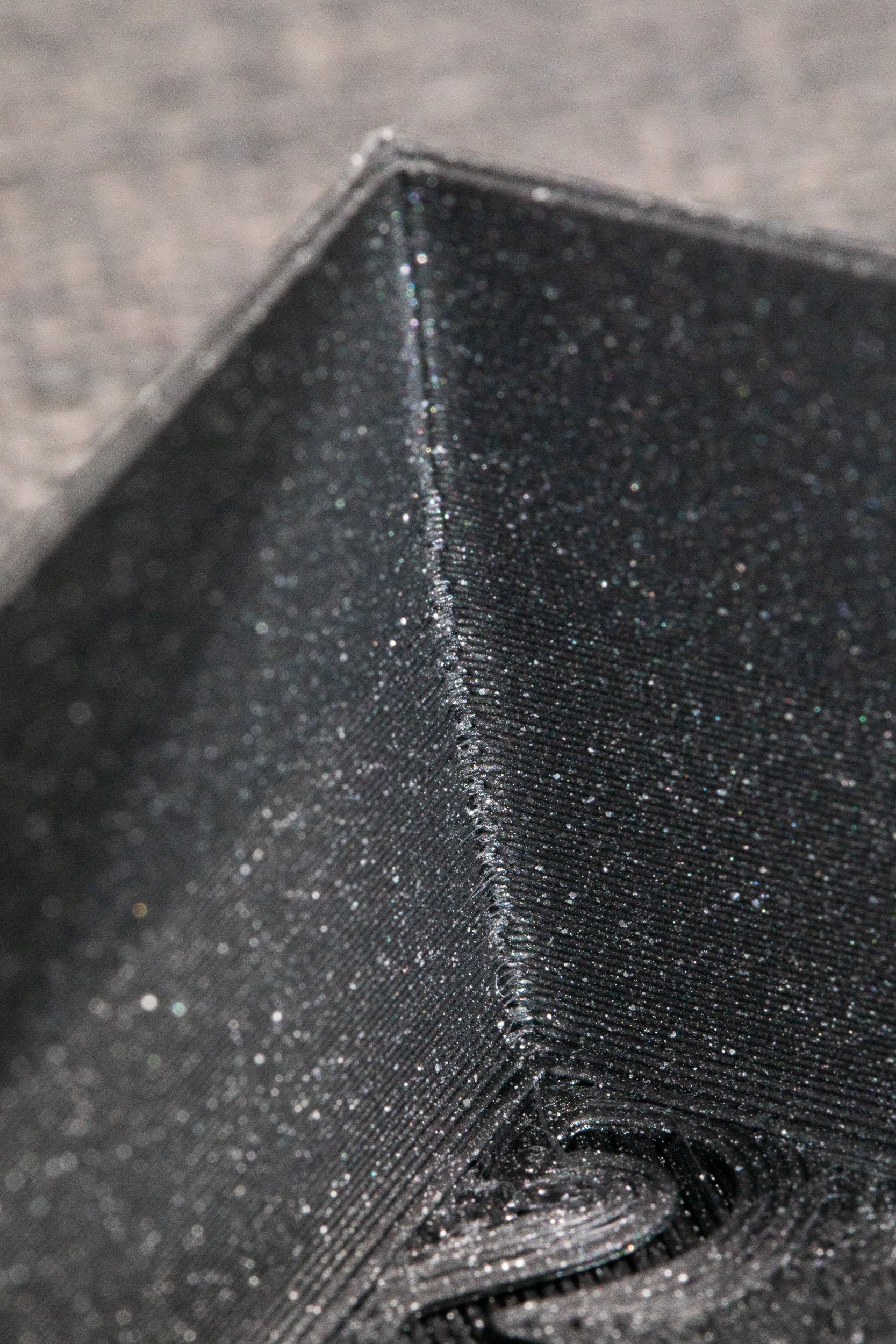

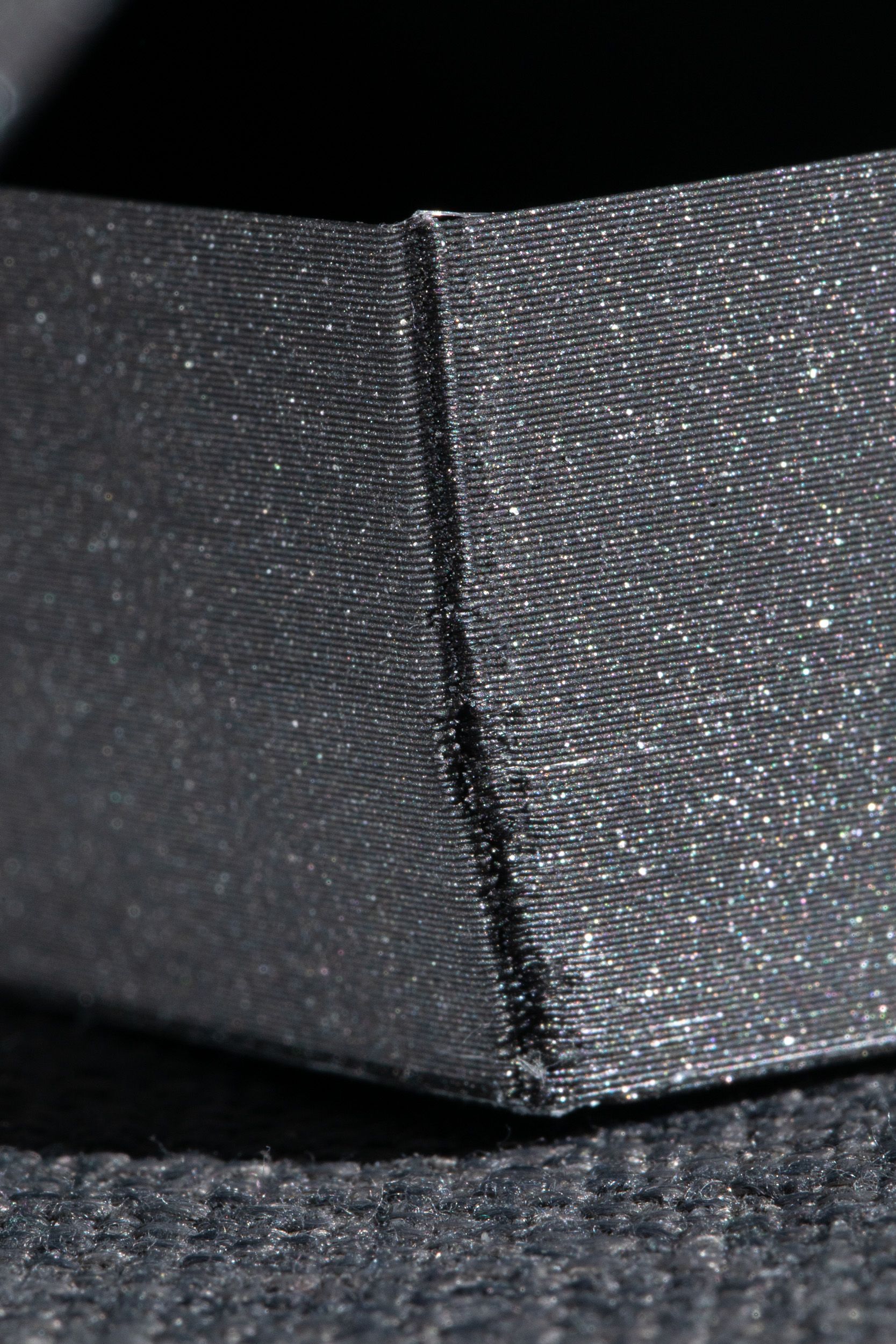

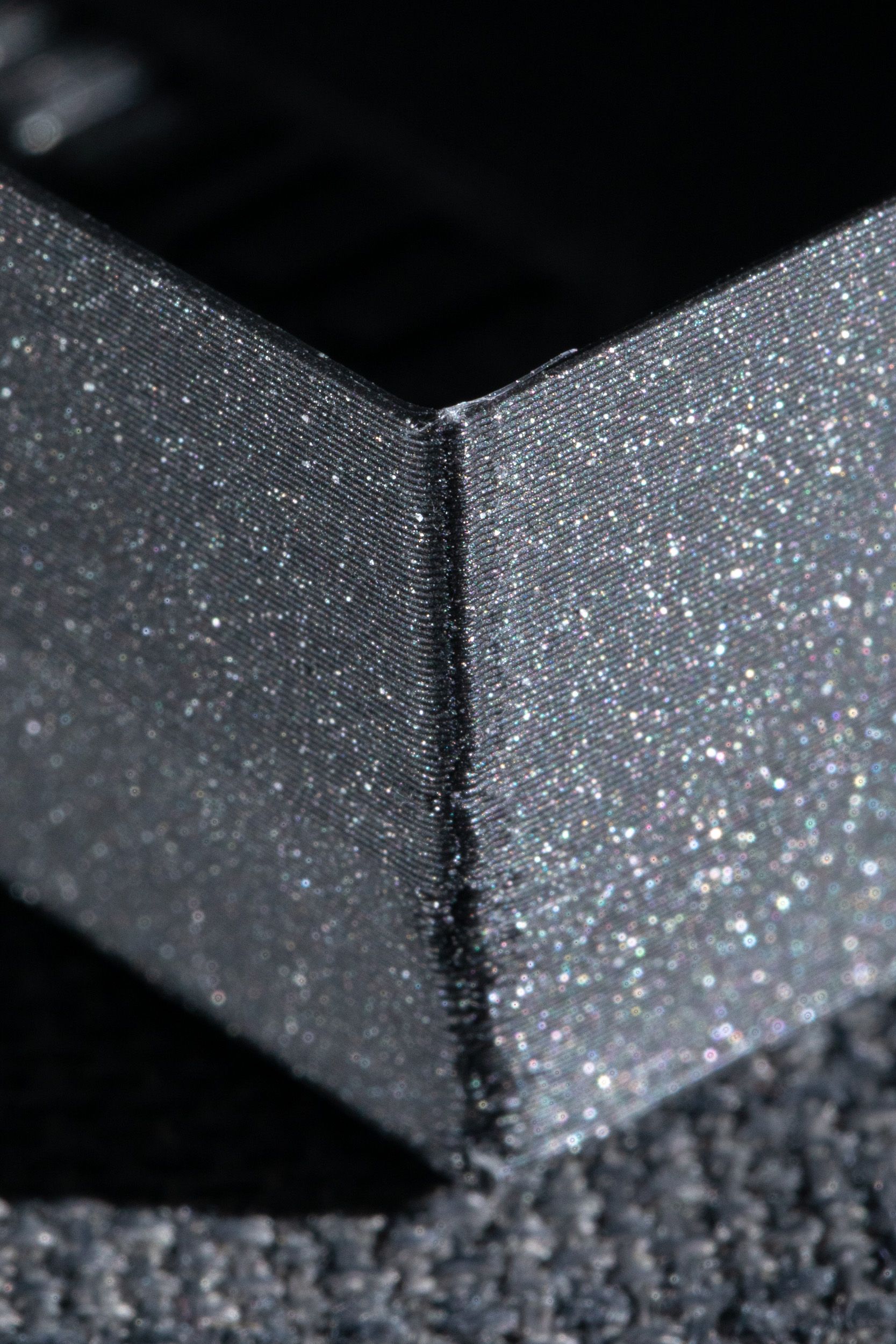

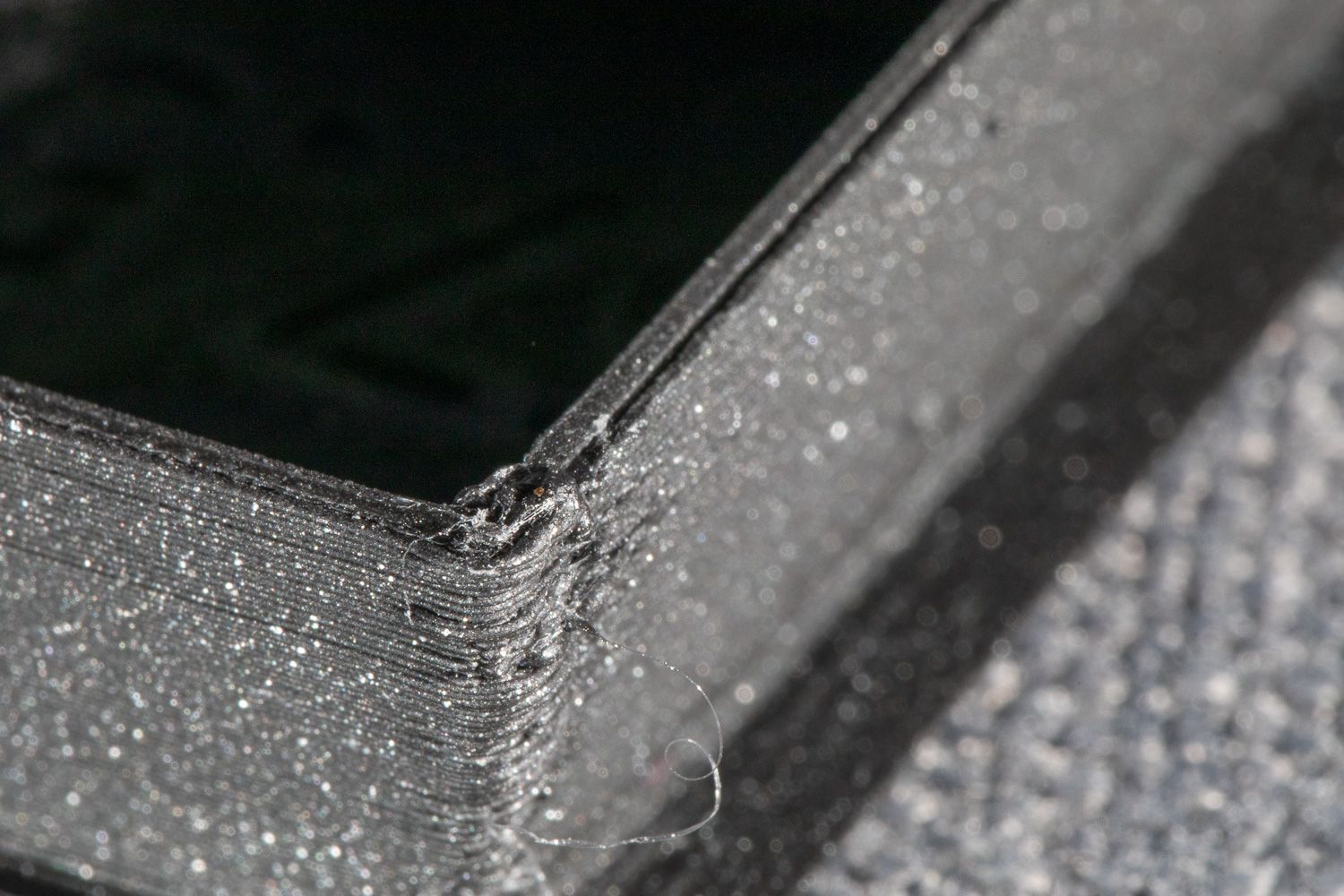

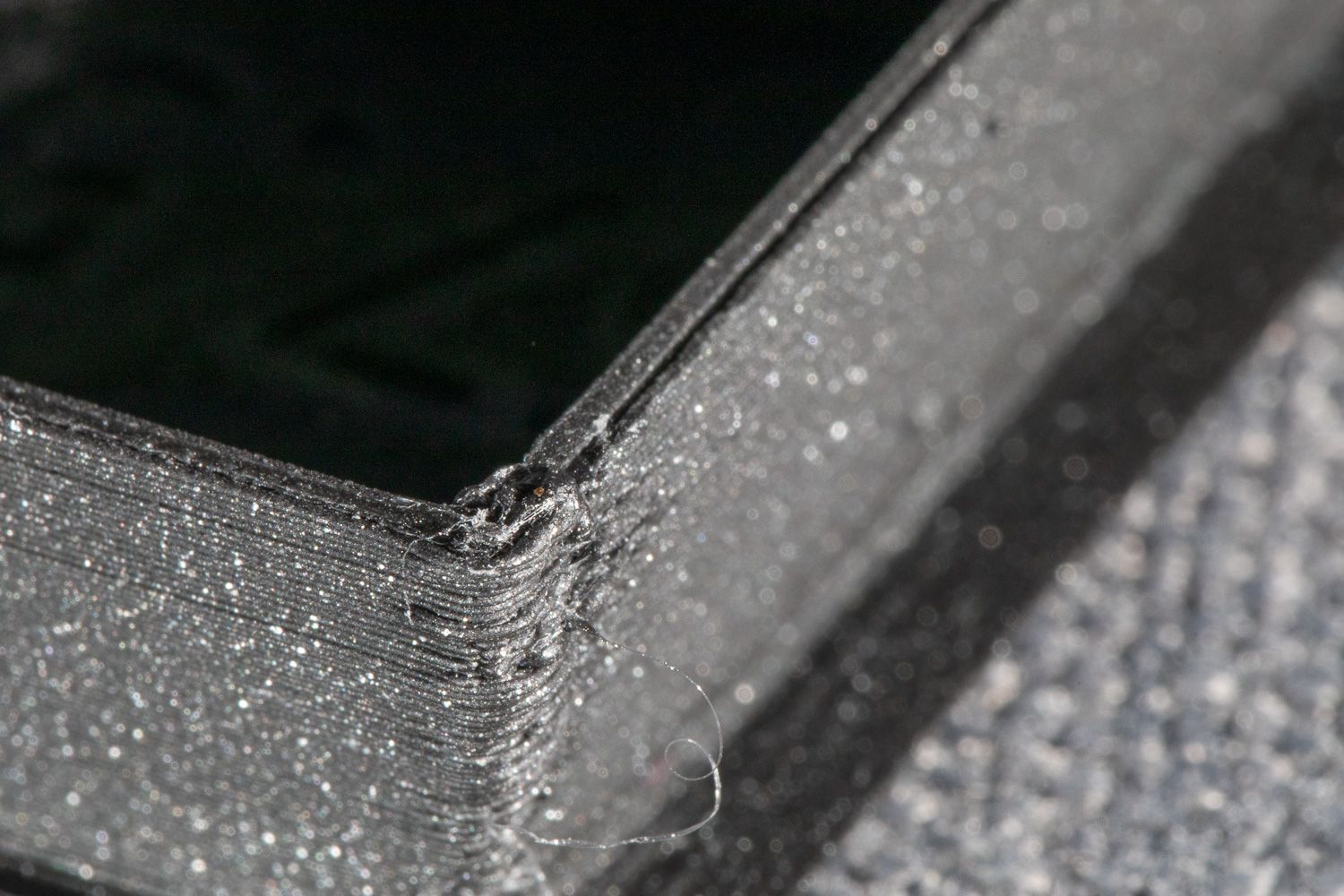

My first approach was to align all seams, but it did not went well. At the seams, excess filament built up a blob of plastic. The print nozzes stumbled over this blob and my tower axes skipped steps, what resulted in a shifted XYZ-Positioning and I have to cancel the print.

At first I took a look in the curling-corners section of the Simlify 3D Print Quality Troubleshooting Guide. It said overheating might be the problem. Thus I reduced the nozzle temp from 230°C to 215°C and turned my nozzle fans to 100% from layer 3 on. At least all no-seam-Corners came out well now. They were a little curly before. How ever, the problem with the seam-edge persisted.

Next approach was to randomly distribute the seams. Finally I did not have to cancel the print, but it came out really ugly.

Next I took a look at the Blobs and Zits section of the Simplify3D guide. It did not help, because it was all about retraction. As far as I can see my extrusion problems are not about retraction, at least the problematic seam-edge had none.

I use:

Printer: Tevo little Monster with:

- duet2 board (running RRF 3.4.4)

- linear rails, magballarms

- duet smart effector

- dual drive flying extruder (20cm bowden tube)

- e3d volcano hot end with 0.4mm NozzleX

Filament: Prusament PLA Galaxy Black

Slicer: PrusaSlicer 2.5.0

However. To me my problem seems more slicer-setting-related (or maybe hotend-related) than Duet- or RRF-related. There are many many tuning knobs in the slicer. I do not know where to start.

I hope this is a common error pattern and you could maybe give me a hint, what I could try to change.