After a quick investigation on PA, it does appear to be much more effective. Key word is 'appears'. Due to the new input shaper causing cornering artefacts (which from now on I will reference as smoothing) this aids in reducing the amount of pressure advance required. More on this later.

The main thing I have tested in this batch is the behaviour of the different input shapers available. I did so by cutting down the original print file into a smaller 10mm slice so the parts can be printed quicker. The slice was chosen to be at the bottom of the original file as this is where most print errors occurred, which coincides with the most amount of long arcing movements. Print speeds and aggression stayed the same.

Duet 2 3.6.a2+3 16xmicro 10kA 14J MZV 51hz.txt

Duet 2 3.6.a2+3 16xmicro 10kA 14J EI3 51hz.txt

Duet 2 3.6.a2+3 16xmicro 10kA 14J EI2 51hz.txt

Duet 2 3.6.a2+3 16xmicro 10kA 14J zvddd 51hz.txt

Duet 2 3.6.a2+3 16xmicro 10kA 14J zvd 51hz.txt

Over all, the prints performed exactly as expected, and all passed without any issues.

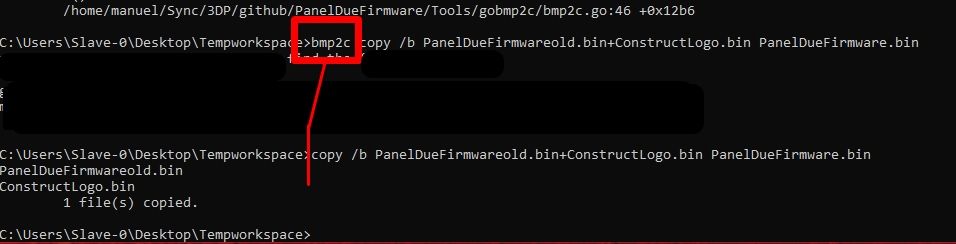

There was one print which did get a Code 3 error, and the main difference was I changed the input shaper type mid printer (after the first layer). This might be an edge case senario but it is interesting that the only time I manually change the input shaper type mid print via inserting custom gcode in the slicer, is the one time it fails. It is also interesting that it didnt fail instantly, it was able to process about 5 seconds more of the print job before the print failed on one of the curved sections.

Duet 2 3.6.a2+3 16xmicro 10kA 14J MZV 51hz fail.txt

After this initial fail, I decided on updating the config.g itself and restarting the mainboard to be the best course of action.

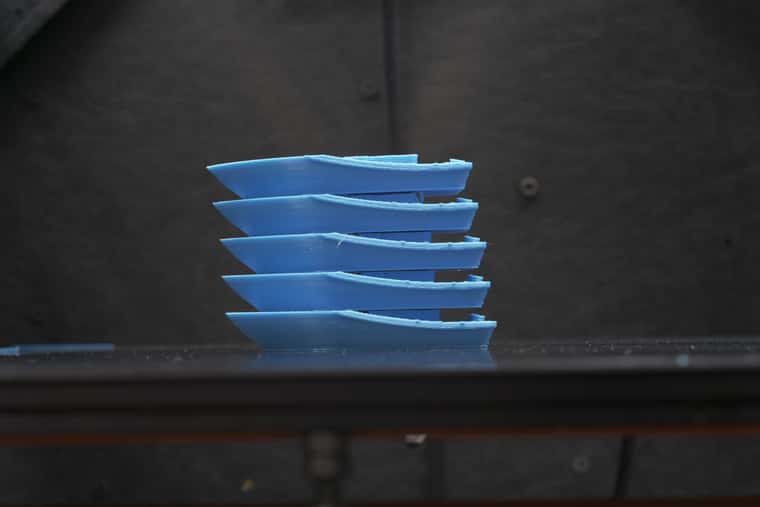

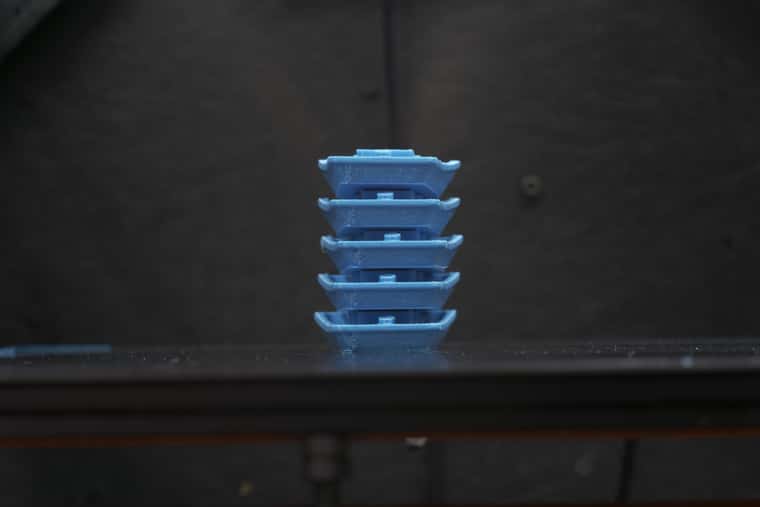

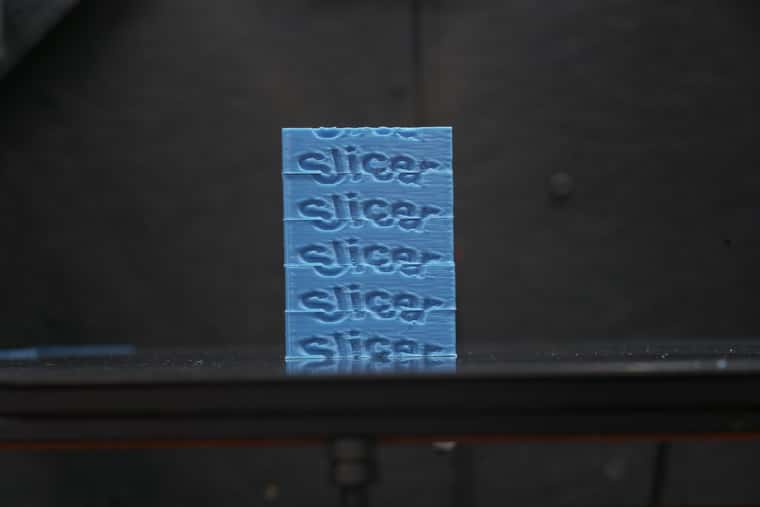

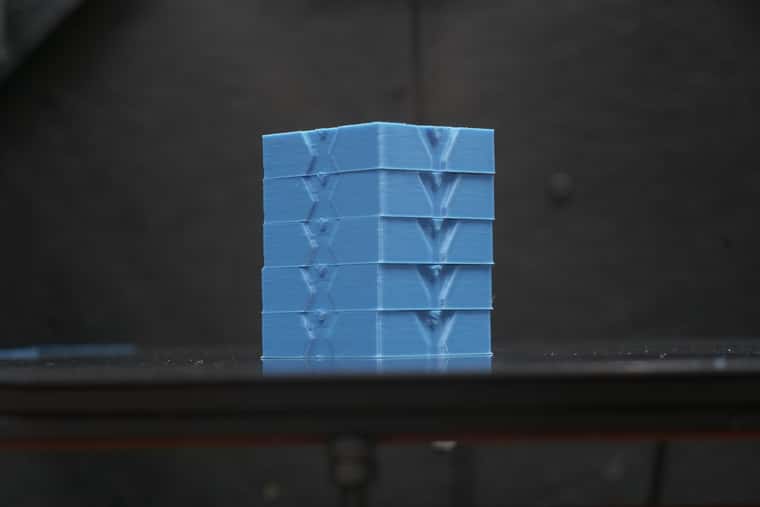

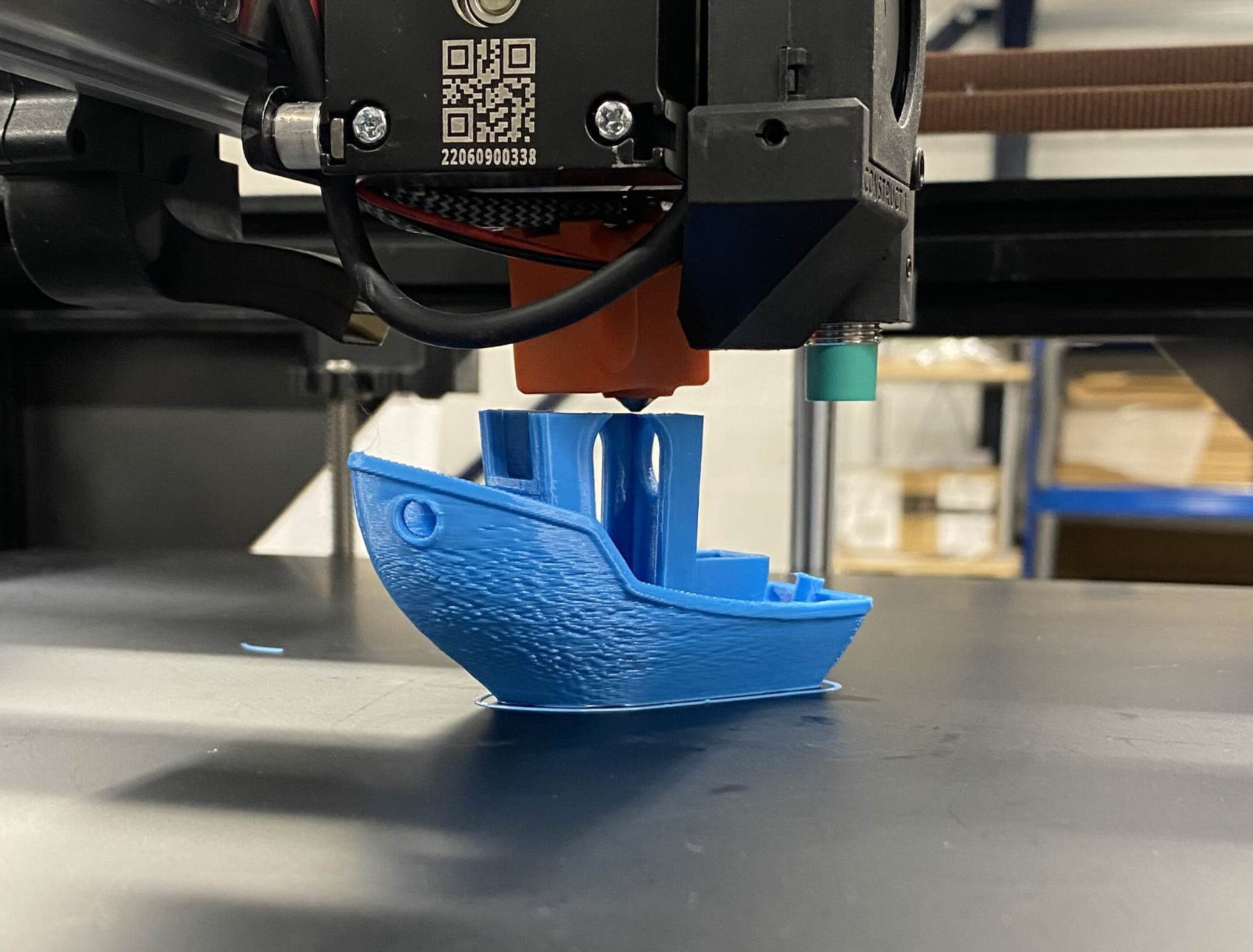

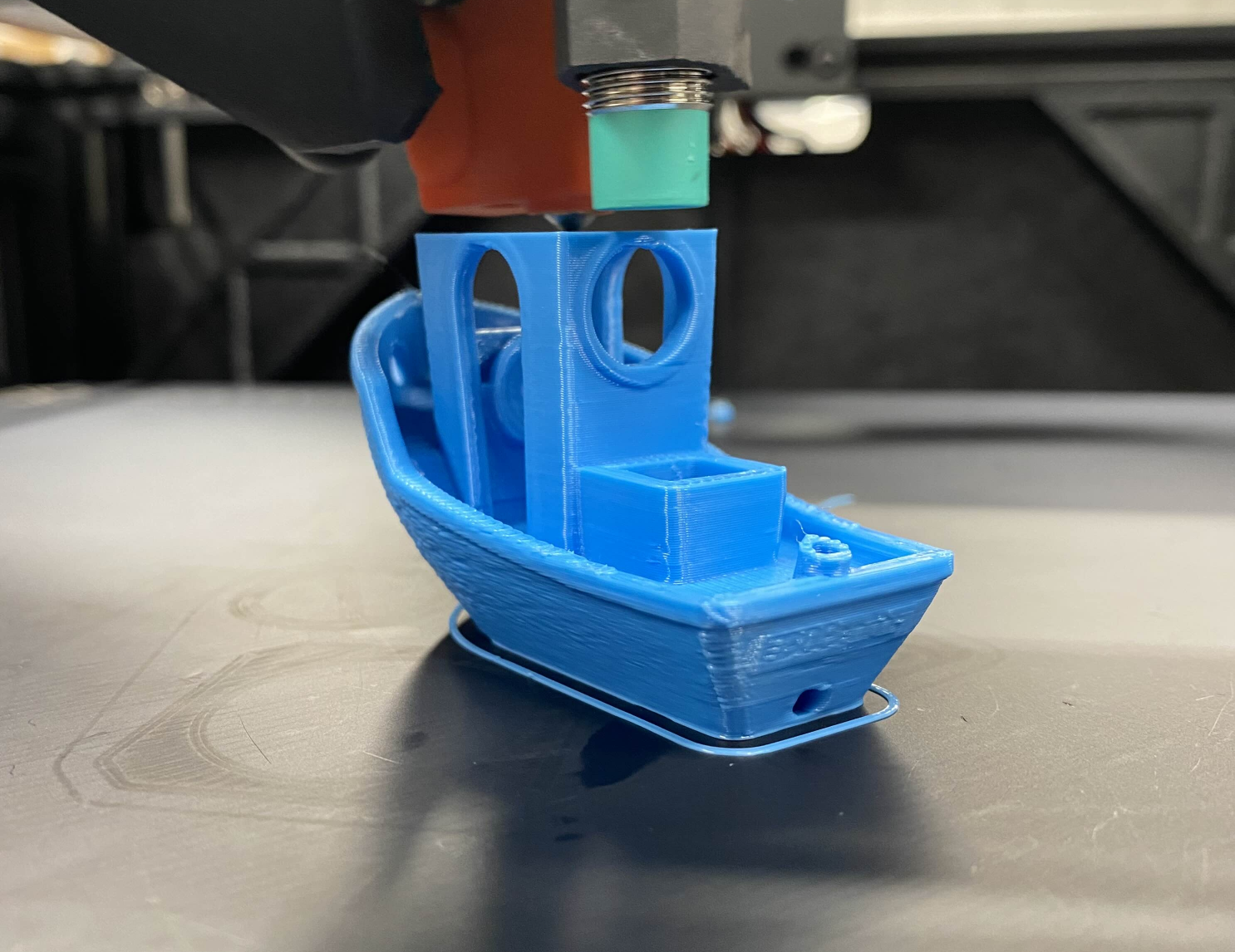

Stacking the print jobs from previous, gives a great example of the input shaper aggression against the amount of smoothing which the input shaper applies.

In order from top to bottom:

MZV, ZVD, ZVDDD, EI2, EI3

The effect of the smoothing is very noticableon the benchy's rear text and the orca slicer logo.

This also leads me to the conclusion that pressure advance should be calibrated to the type of input shaper used, as more aggressive input shapers require lower values of PA for the same clarity.

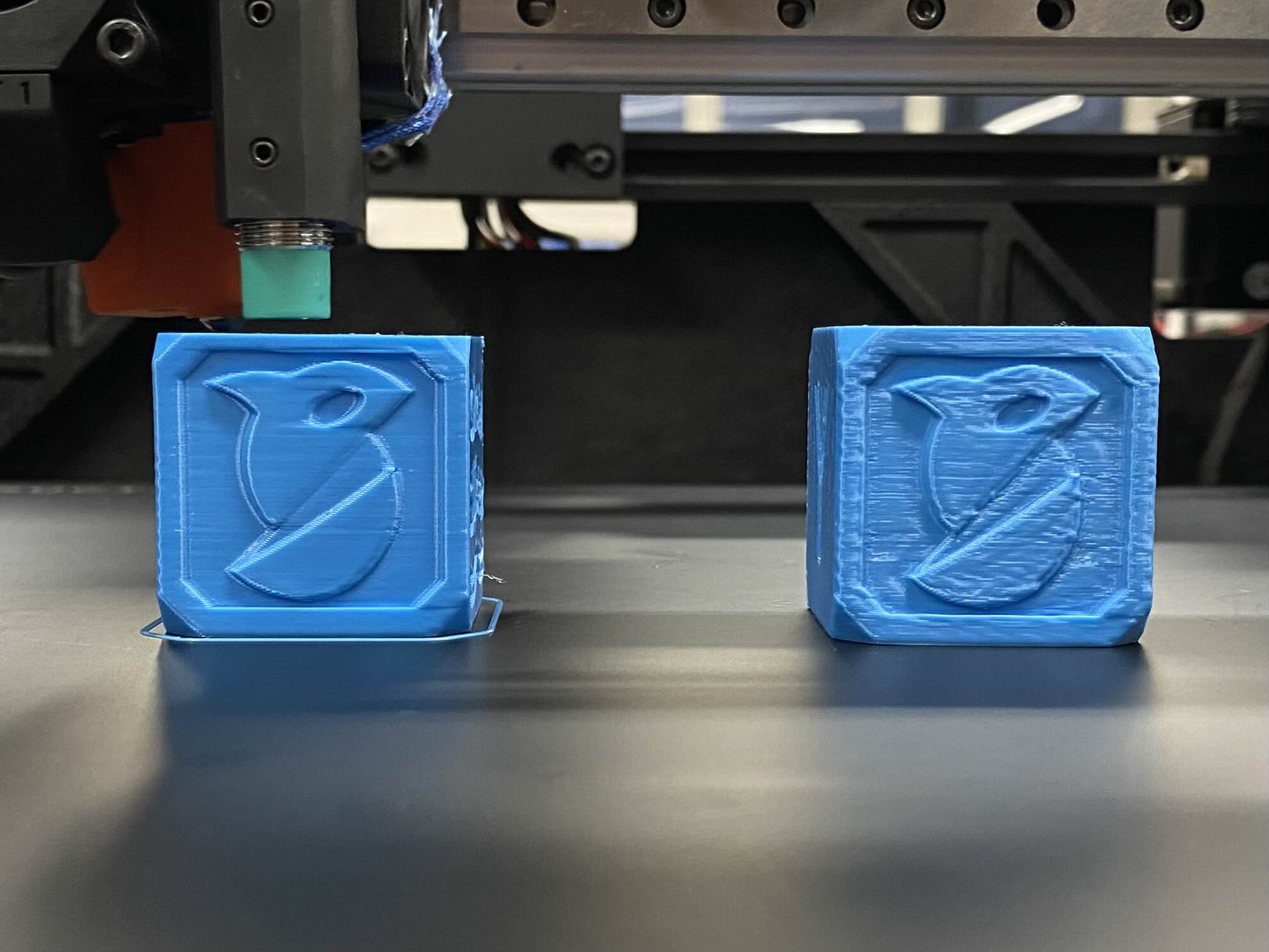

I personally use EI2 as my go to shaper of choice. and at 51hz I was able to lower my PA value from 0.0225 to 0.0085, which in-turn also sped up my overall print speeds without sacrificing any quality.

One final test I completed (no pictures sadly) is using MZV on an extremely low frequency which would normally never be used in actual machines, in hopes to overload the MSU.

The output print quality was decent, however showed massive amount of smoothing almost 10x worse than EI3 in the previous tests.

This leads me to the conclusion that the input shaper should only be used on frequencies above 40hz, and the lower the frequency you go, the simpler the input shaper should be used. I.E dont use EI3 over MZV at 30Hz.

Duet 2 3.6.a2+3 16xmicro 10kA 14J MZV 20hz.txt

I am starting to run out of things to test on my dedicated test machine, so I have selected a handful(8) of print farm machines which i have deployed 3.6.A2+3 on to. So far the output has been a marked improvement in print quality. No known errors or issues has appeared yet.

Any advice on specific areas I should focus my testing onto would be much appreciated. if not my next batch will be all the input shaper types at very low and very high frequencies.

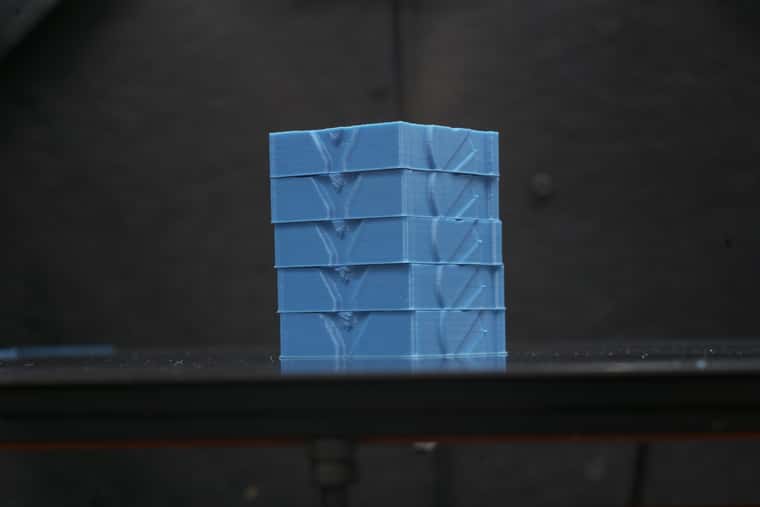

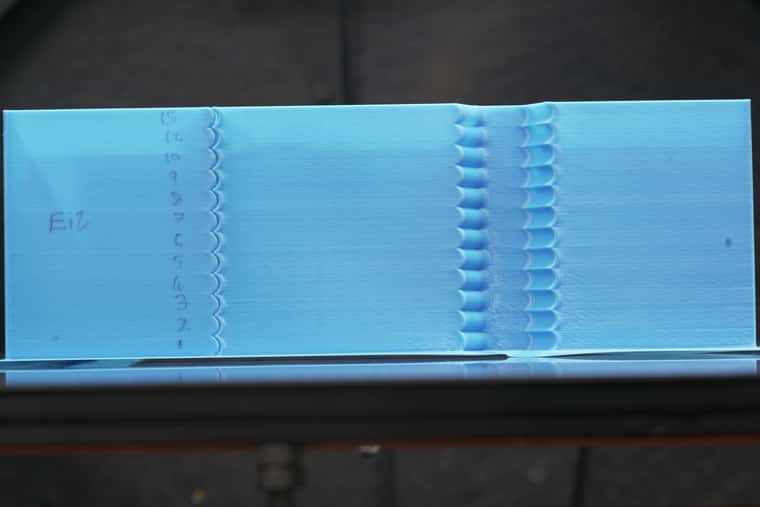

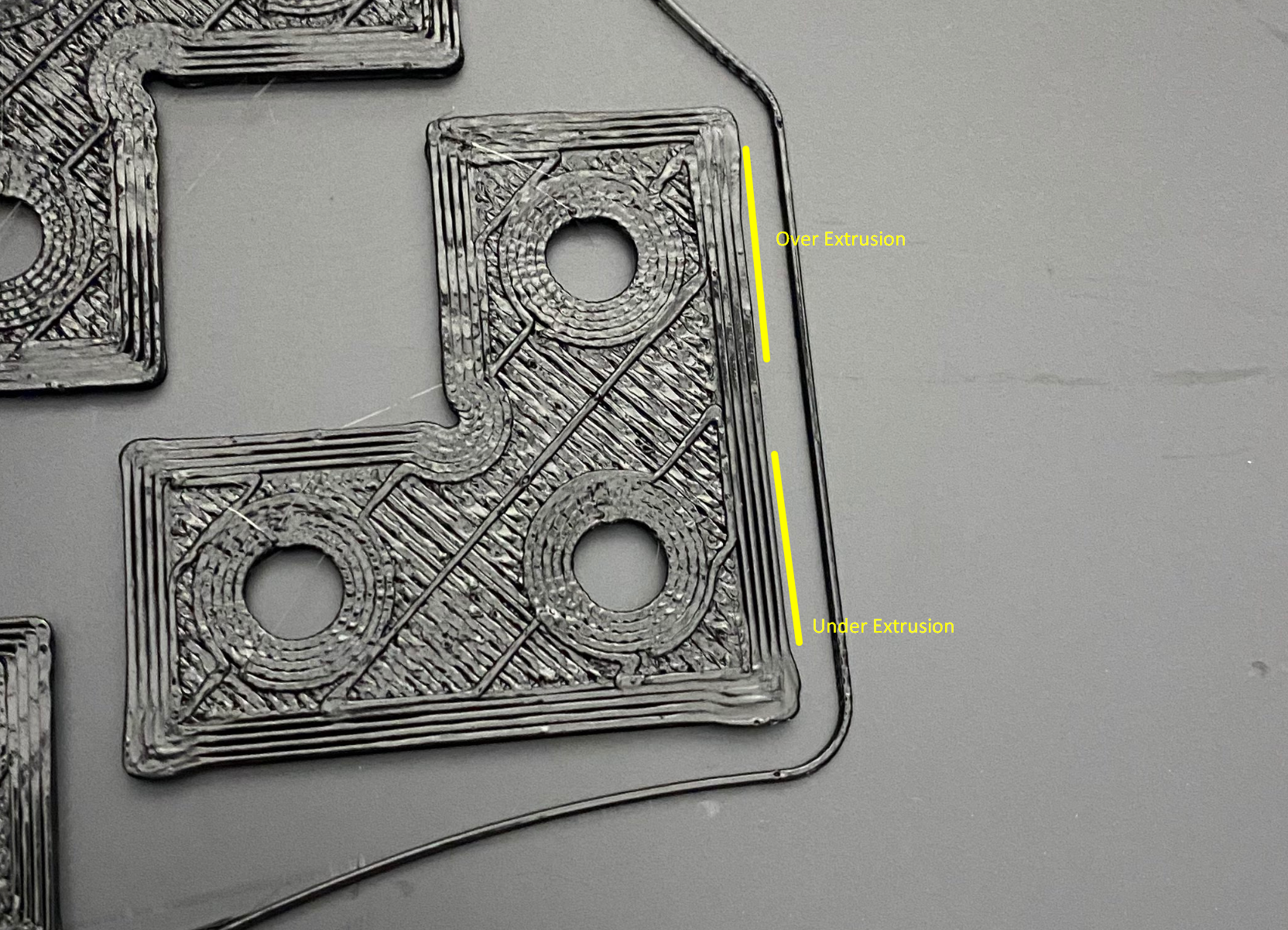

Pictured is PA0.035

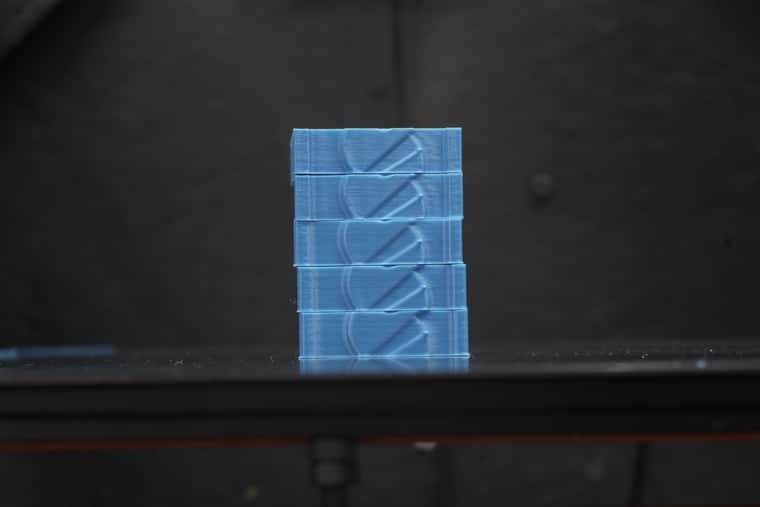

Pictured is PA0.035