First, apologies for the lack of updates. I started doing testing today, and have reached out to various content creators hoping for some assistance with this side of things. Time to do testing has just not been on my side.

Today I did some very simple vase mode prints to check two things:

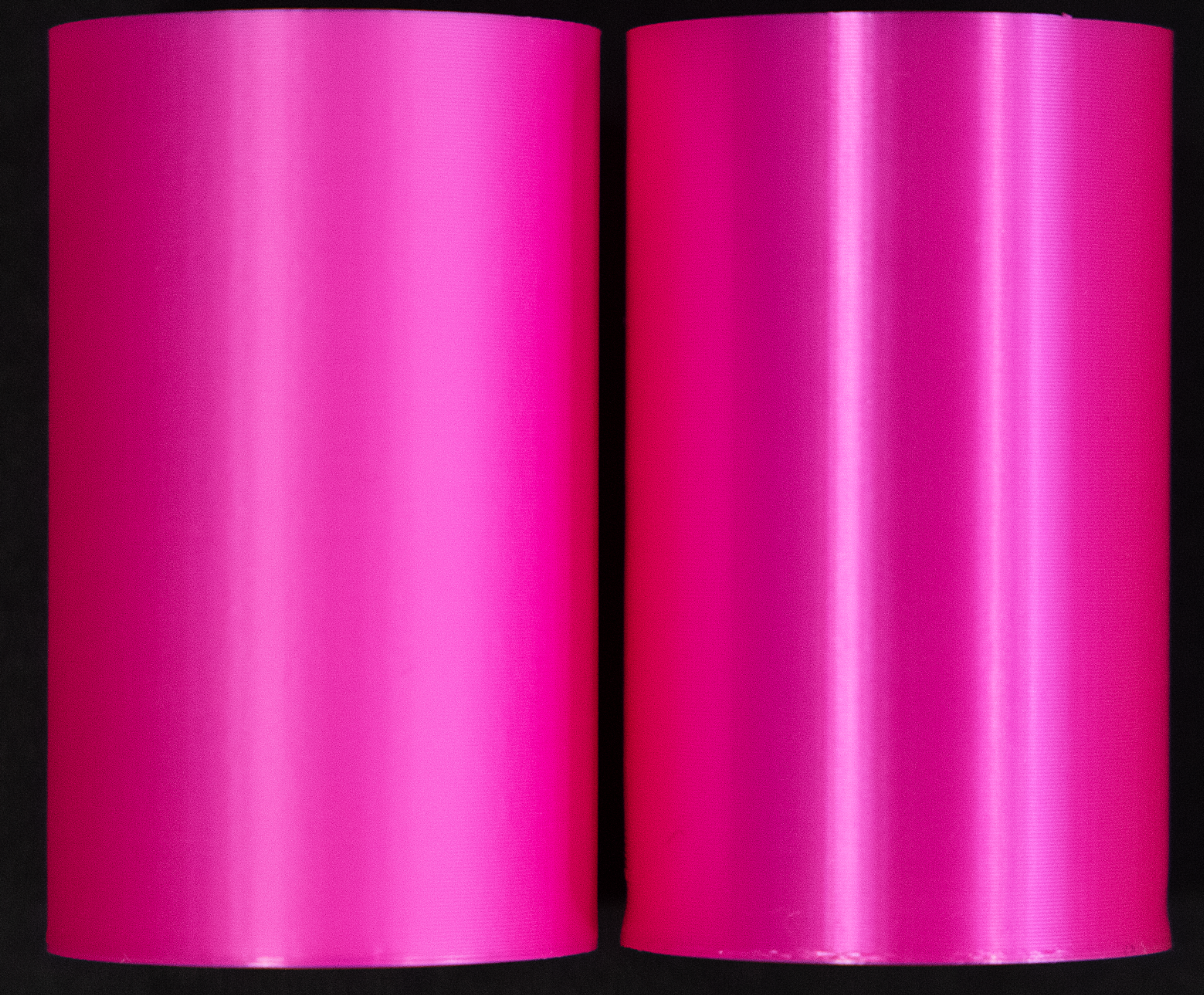

- potential change in surface finish

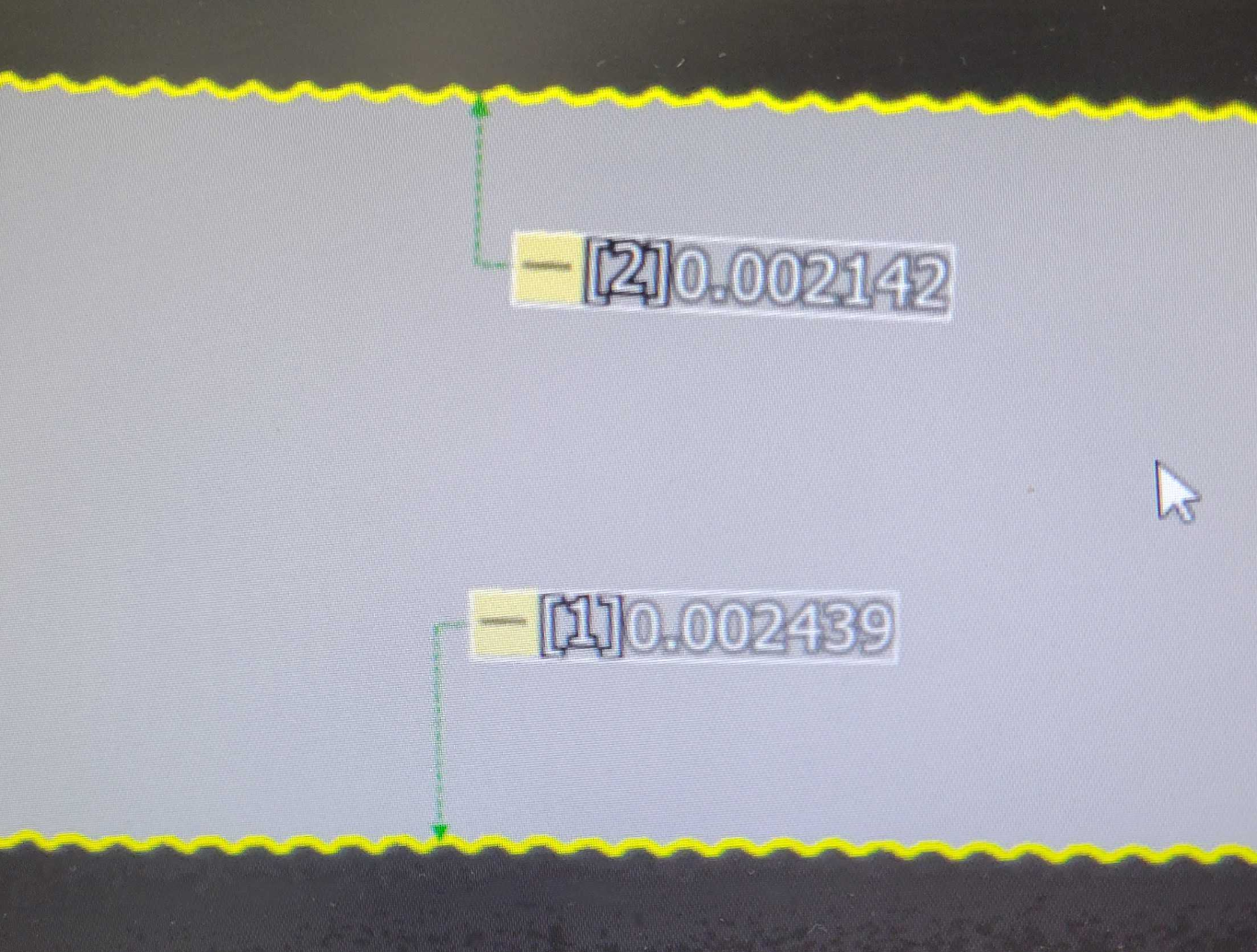

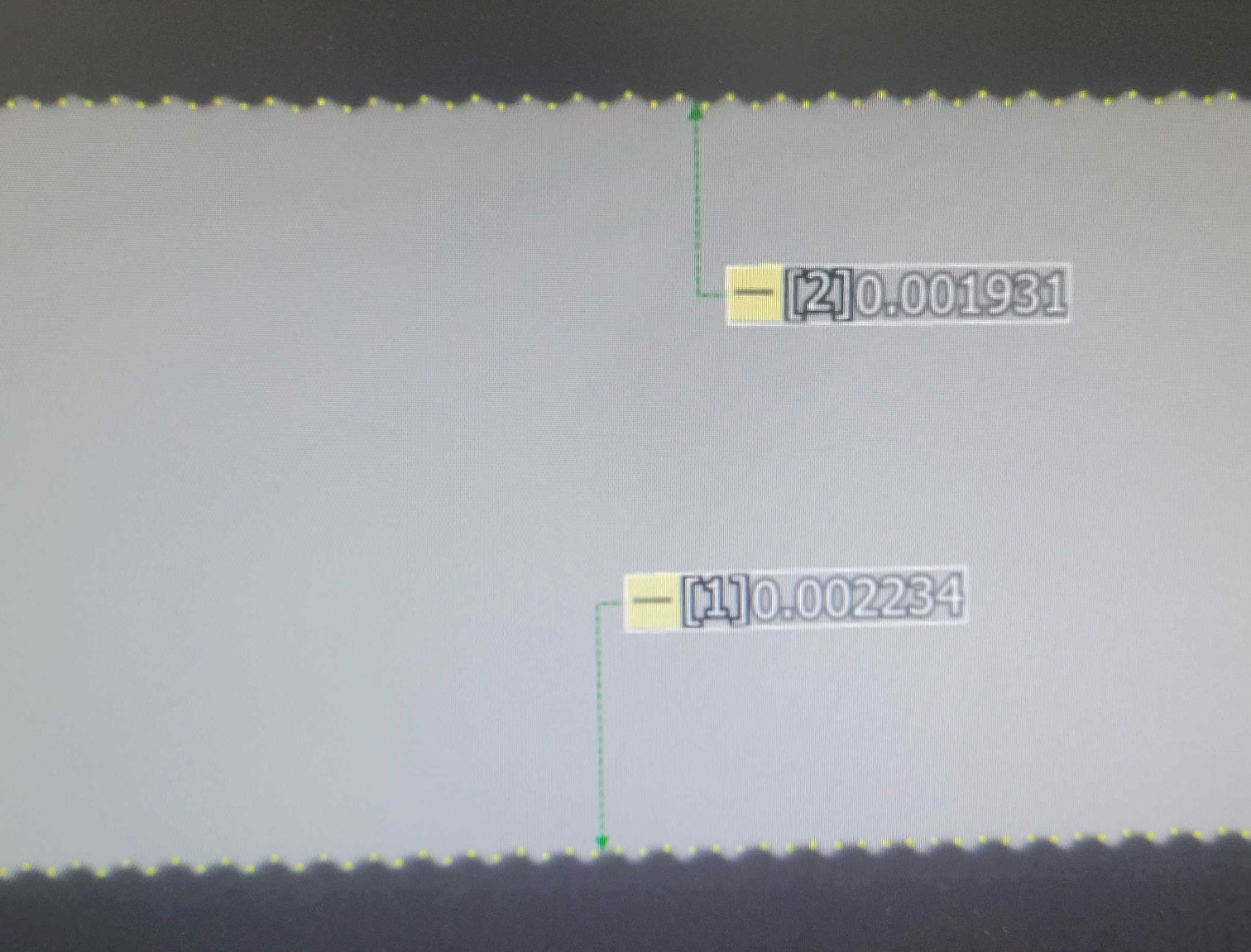

- ability to take objective measurements of layer width

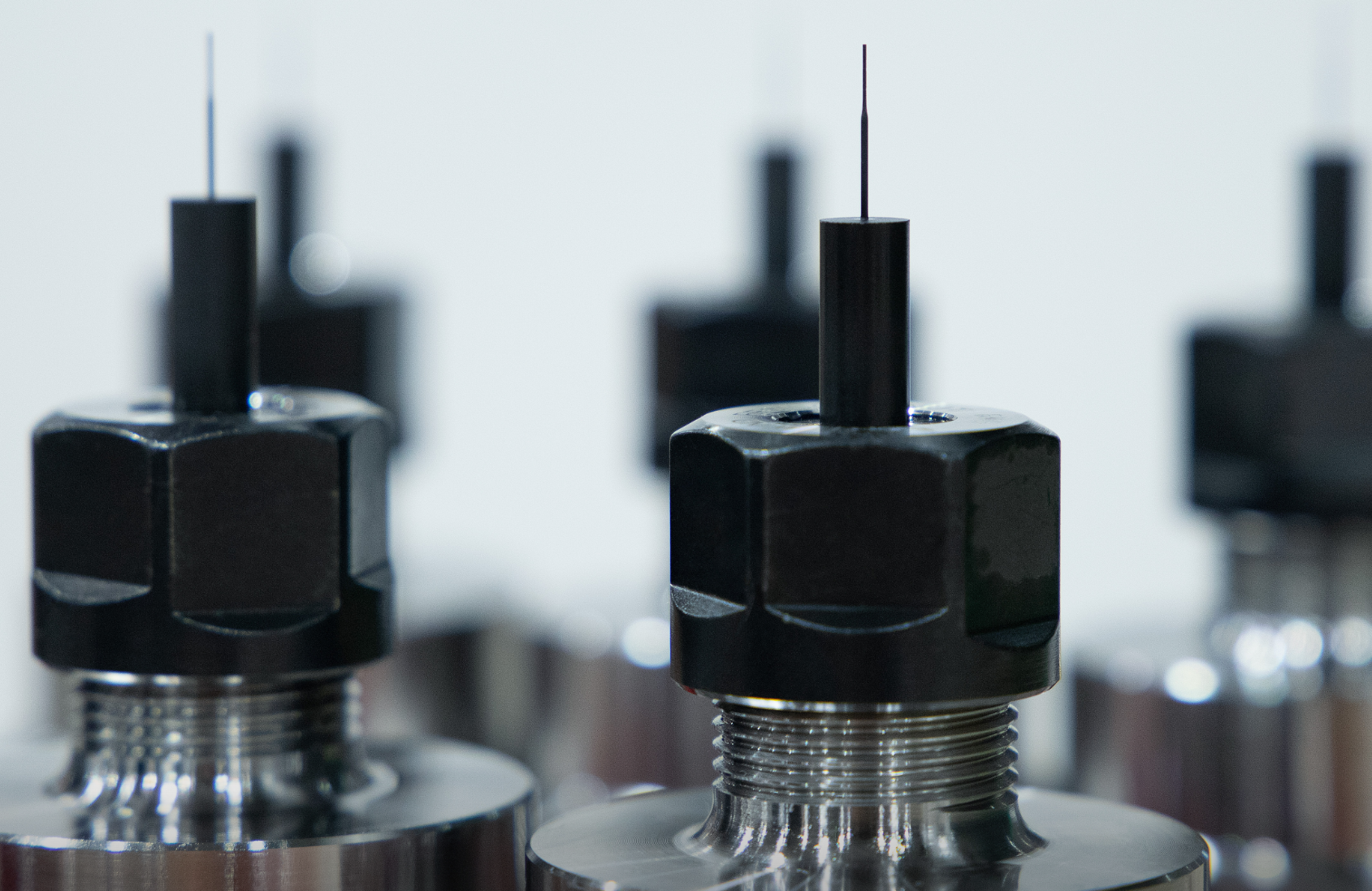

The prints were done on an E3D toolchanger, using a Hemera extruder and Copper V6 block. Both prints were done with the exact same hardware, only the nozzle being different. I used a hardened steel E3D V6 nozzle as the control. The material was the same spool of Prusament PLA, fed closed loop from a material dryer.

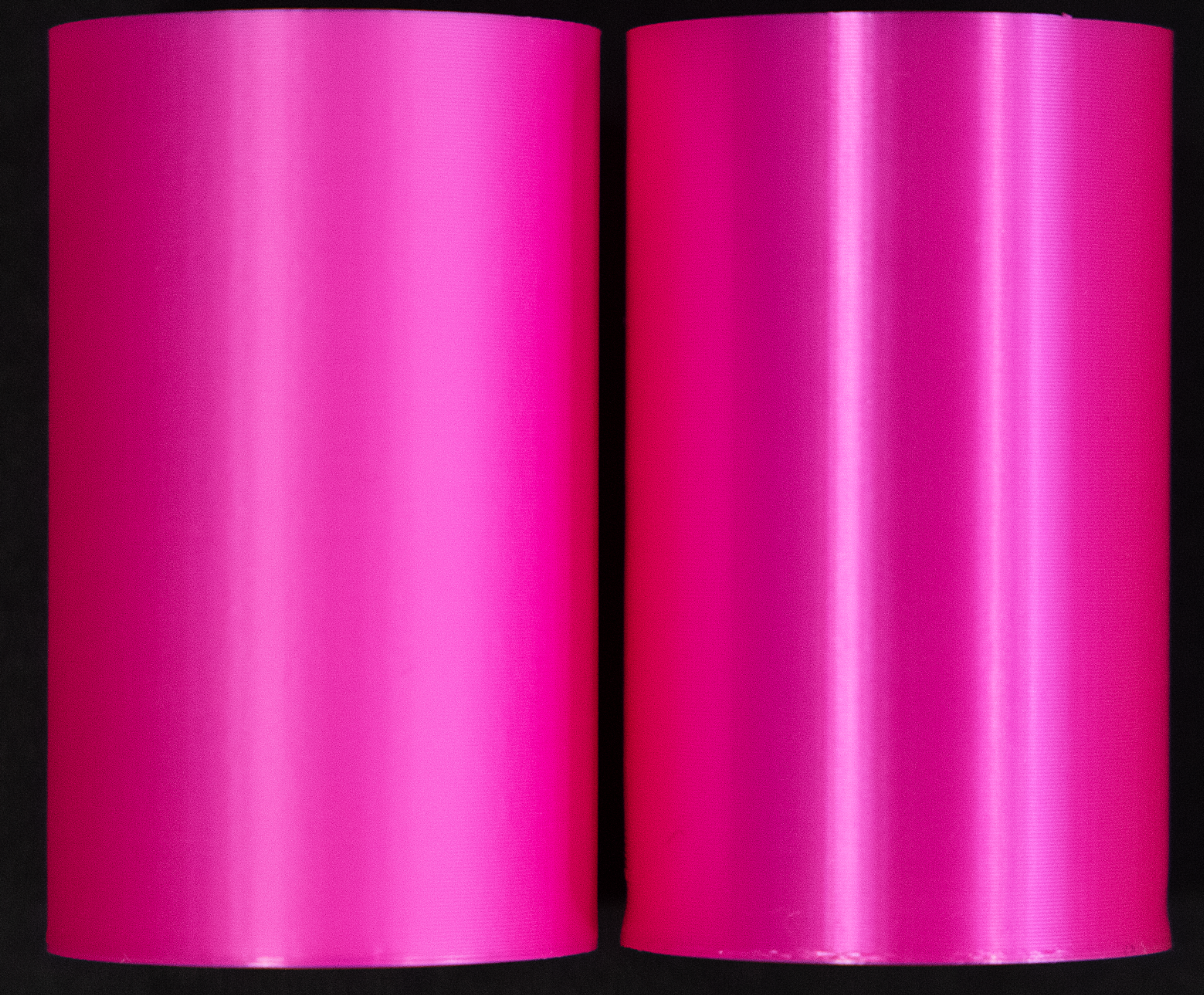

First impression: the ADV nozzle produces a significantly more matte finish. Though "improvement" is completely subjective, it objectively hides layer lines more than the gloss, especially in person. The photo posted was spliced together as both parts were taken under identical lighting conditions.

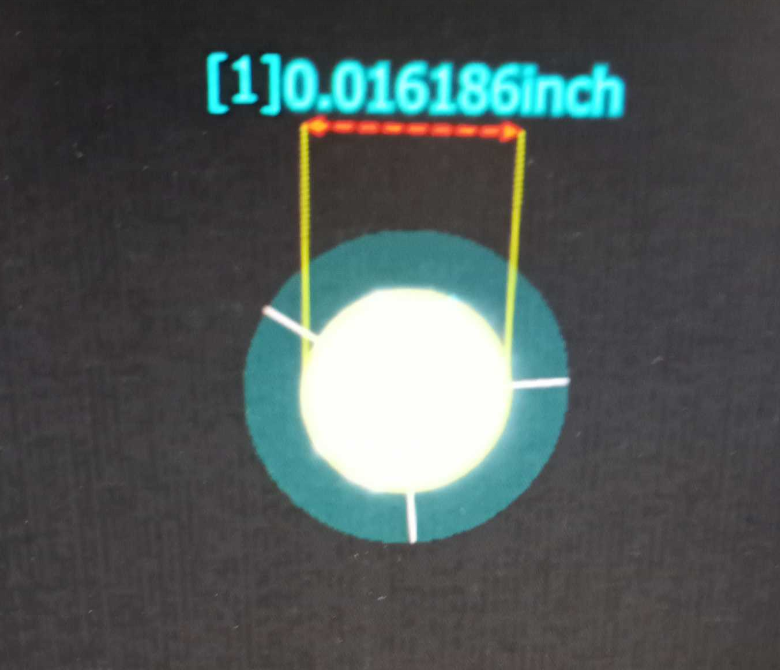

The next step is to use our IM to take measurements of wall thickness and layer width, to determine if there is any significant difference in extrusion consistency (visually, I'm not expecting much difference).

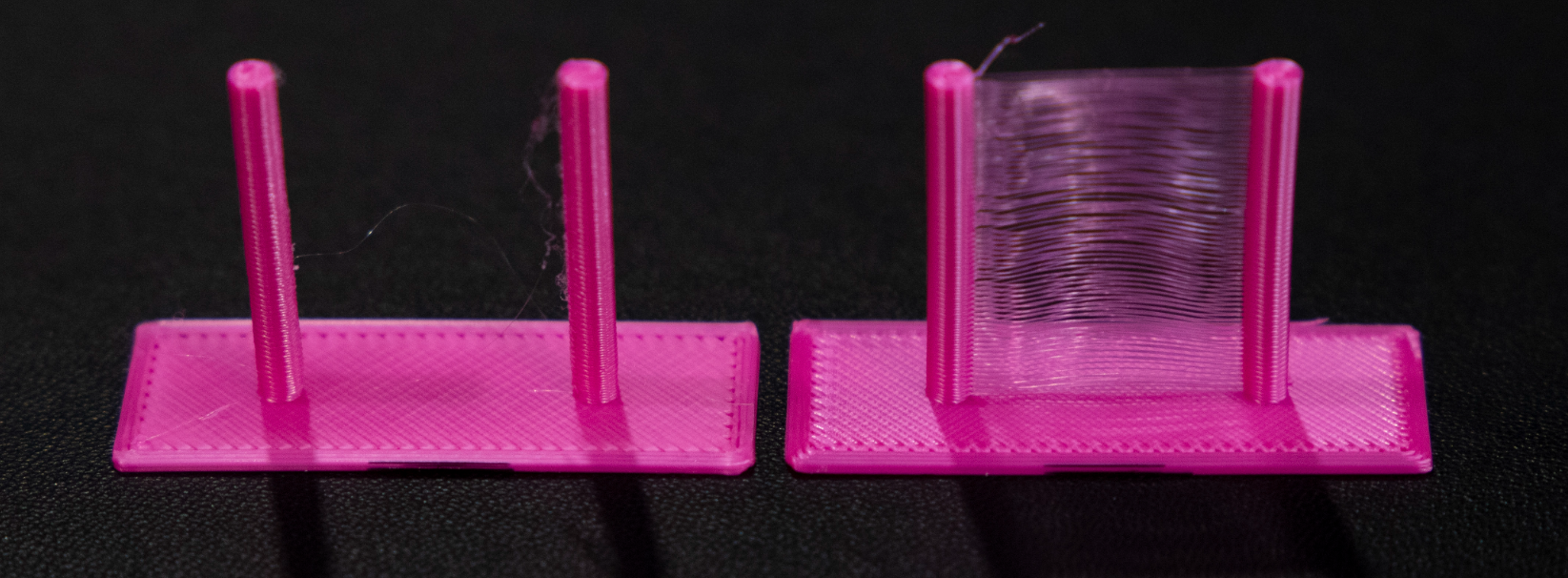

Anecdotally, the ADV nozzle oozes considerably less than the V6. The next steps will be various retraction prints, sans retraction, to evaluate stringing/oozing.

Finally, I had some mushrooming at the bottom of the V6 print. This is obviously not a fault of the nozzle.

I'm not expecting too much enthusiasm over the initial results, but I'm happy so far and am very excited to get to the retraction tests. My first reaction is that will be the area most improved.

ADV left, E3D right

I will leave this post up out of shame.

I will leave this post up out of shame.