OK, so after 4+ years (  ), I donated the printer to a friend and came back to this issue. I will leave the fix here, if others hit it .

), I donated the printer to a friend and came back to this issue. I will leave the fix here, if others hit it .

Disconnecting the thermistors had no effect. The indicated temp was still around 66 degrees now (yes, it degraded over time).

Compared bed, E0 and E1. Measured resistors, voltages. Short circuiting indicated 2000C, as expected. E1 was different from bed and E0 in measured values (3.3 V compared to 3.1V on the others the measuring pin).

Long story short, replaced C19 (the bad guy, or C18 looking at the picture. The one that filters the E0 sensor signal) with C65 (donor) and everything works as in the first day.

Best posts made by sigxcpu

-

RE: Thermistors measure too highposted in Duet Hardware and wiring

-

RE: Duet Maestro Freefallposted in Firmware wishlist

Or you can wait to get old. My printer is almost quiet, I just need few more years

-

Filament loading with stall detectionposted in Example setups and prints

Based on @dc42 idea here: https://duet3d.dozuki.com/Wiki/Stall_detection_and_sensorless_homing#Section_Using_extruder_stall_detection_during_filament_loading

I did the following filament loading macro that works for me:

M302 P1 ; enable cold extrusion M201 E1000 ; reduce extruder acceleration M915 P3 S10 F0 R0 ; set stall detection threshold M913 E100 ; set extruder motor to reduced % current M83 ; relative extrusion G1 S1 E800 F3600 ; move fast 500mm of filament M913 E100 ; set extruder motor to full current M302 P0 ; disable cold extrusion G1 E50 F300 ; extrude slowly 50mm of filament M98 Pset_accel.g ; restore acceleration valuesset_accel.gis used to set working accelerations for all axes after sensorless homing of X and Y. It has the following content:M201 X2000 Y2000 Z100 E9000 ; Accelerations (mm/s^2) -

RE: Dedicated Multicolor LED Plugposted in Hardware wishlist

… play Doom on PanelDue while printing?

-

RE: Infill Too Fast? Over Extrusion on Short Vectorsposted in Tuning and tweaking

Post some pics, but I bet there is also some over-extrusion going, which adds to the pressure build-up (btw, did you try pressure advance?).

Some time ago, I've attended a machining exhibition and noticed something at Stratasys stand: in all their demo prints you can clearly see the infill lines in top/bottom. They are not squashed trying to generate a smooth top layer. Then is when I've realised that I was overextruding all the time, trying to get rid of that small spacing between the tops of the oval beads of the infill.

Since then, I've adjusted my extrusion factor to always see the top spacing, but they still touch in the middle and the quality of my prints improved a lot.

-

RE: DWC feature request: discrete speeds on the speed barposted in Duet Web Control wishlist

+/- buttons would be very helpful for mobile devices. I don't know about others, but that slider on Safari on IOS is painful. Sometimes it simply jumps at one end and 150% extrusion is not nice for sure.

-

RE: can't melt abs, or use "reply"posted in General Discussion

Your thermistor, the wires or the way it is mounted are bad. Never had any temperature issues even with the cheap thermistors.

Can you post a picture of your hotend?

At 600F (315C) many things will go bad, so try to avoid that.

-

RE: Help with Steps per mm Calculationposted in Tuning and tweaking

@snowcrash said in Help with Steps per mm Calculation:

Thanks for everyone who replied!

That's a really interesting discussion and I think it illustrates perfectly why it tends to get my brain twisted up with all the terms, partly because...

@aidar said in Help with Steps per mm Calculation:

@dougal1957 Got it. But i am sure by 25mm and 12 mm OP means lead then, not pitch.

Actually, I did mean 'pitch' rather than 'lead' - and I'm not going by what I know here (as I know close to nothing on this), but by the documentation.

Check out the link I provided to the products' page on Igus and see what it says there, or if you prefer, here's a snapshot of the 2 relevant rows in the listing:

Actually that is "lead". I find it amazing that Igus confuses "lead" and "pitch".

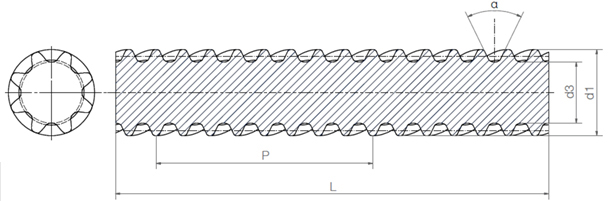

Check their drawing before the table:

https://www.igus.com/contentData/wpck/images/global/1_1/dst_spindeln_zg.jpgThat

Pis clearly "lead", not "pitch". The pitch is the axial distance between adjacent threads. They measure the "pitch" as distance between the ridges of the same thread, which actually is the "lead" - axial advance after you turn the screw 360 degrees (1 turn). -

RE: Meanwell Power Supply AC Ground and V- Connectionposted in General Discussion

Are you talking about that capacitor connection?

-

RE: Meanwell Power Supply AC Ground and V- Connectionposted in General Discussion

Yes. That is a capacitor. Maybe some noise supression thing. That is not a direct connection to ground.

-

RE: Crimping Toolposted in General Discussion

I have this and it is amazing. Re-did all my previously connectors made with pliers.

-

RE: Duet 3 demo at TCTposted in General Discussion

@phaedrux said in Duet 3 demo at TCT:

Currently the DWC runs on the same CPU on the Duet that also handles everything else the printer has to control. It used to run on the even slower wifi chip.

Duet 2 = 120MHz 32-bit, ESP8266 = 160 MHz 32-bit.

I think moving the web task to the main Duet 2 chip was because there is no ESP8266 in Duet 2 Ethernet.

And in terms of performance, that is a mistake, because the main chip has realtime tasks to do while ESP8266 is mostly idle now.