@dc42 Thanks for the reply,

running this firmware resolves the issue, it now Scans as expected in the X axis and the mesh generated also looks correct.

Posts made by Superbrain8

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

no that one still persists, the mesh is scanned in the Y axis instead of the X Axis but is generated as if scanned in the X Axis

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@gloomyandy that fixed that issue, thanks.

will see how the original issue for this post is fixed too -

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@T3P3Tony installed the new firmware, homed the printer but it still fails to home the Z axis

here is a M122 after the failed home attempt=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-beta.4+2 (2025-02-18 10:06:11) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: YQ6KF-K096U-D65J0-40KMG-4G03Z-H28XK Used output buffers: 1 of 40 (22 max) === RTOS === Static ram: 94764 Dynamic ram: 97496 of which 12 recycled Never used RAM 49196, free system stack 188 words Tasks: NETWORK(1,ready,10.2%,235) LASER(5,nWait 7,0.0%,269) HEAT(3,nWait 6,0.0%,350) Move(4,nWait 6,0.0%,353) TMC(4,nWait 6,0.8%,99) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,353) MAIN(1,running,86.2%,659) IDLE(0,ready,1.8%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,269), total 100.0% Owned mutexes: === Platform === Last reset 00:00:14 ago, cause: software Last software reset at 2025-02-23 14:59, reason: HeatTaskStuck, Gcodes spinning, available RAM 49124, slot 0 Software reset code 0x0143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0000080f BFAR 0xe000ed38 SP 0x200117d8 Task Move Freestk 1018 ok Stack: 00000000 2001112c 10000000 e000e000 20000f4c 0009f255 0009fa40 61000000 20016e08 200235b8 200235b8 20023530 00053f71 00007ff0 00000001 00056d53 a5a5a5a5 200235b8 20023538 00000000 a5a5a500 418a2040 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 0.7ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 No step interrupt scheduled Driver 0: standstill, SG min 4, r/w errs 0/1, ifcnt 63, reads/writes 741/14, timeouts 0, DMA errs 0, CC errs 0 Driver 1: standstill, SG min 10, r/w errs 0/1, ifcnt 63, reads/writes 741/14, timeouts 0, DMA errs 0, CC errs 0 Driver 2: standstill, SG min 0, r/w errs 0/1, ifcnt 64, reads/writes 741/14, timeouts 0, DMA errs 0, CC errs 0 Driver 3: standstill, SG min 2, r/w errs 0/1, ifcnt 63, reads/writes 741/14, timeouts 0, DMA errs 0, CC errs 0 Driver 4: standstill, SG min 0, r/w errs 0/1, ifcnt 64, reads/writes 741/14, timeouts 0, DMA errs 0, CC errs 0 Driver 5: not present Driver 6: not present === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 11: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Driver 10: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 168, received 761, lost 0, ignored 0, errs 0, boc 0 Longest wait 2ms for reply type 6061, peak Tx sync delay 351, free buffers 26 (min 25), ts 70/69/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 5.21ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.2.1 Module reset reason: Power up, Vcc 3.42, flash size 2097152, free heap 39332 MAC address f0:08:d1:02:e5:fa IP address 192.168.178.47 Signal strength -42dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0 -

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

Homed 3 times and ran M122 after each unsuccessful home

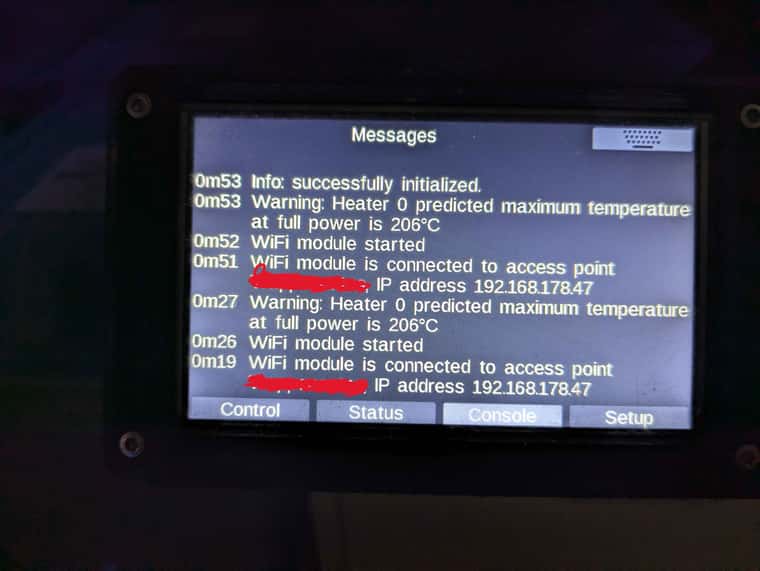

=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-beta.4 (2025-02-11 09:50:58) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: YQ6KF-K096U-D65J0-40KMG-4G03Z-H28XK Used output buffers: 1 of 40 (24 max) === RTOS === Static ram: 94732 Dynamic ram: 97496 of which 12 recycled Never used RAM 49228, free system stack 196 words Tasks: NETWORK(1,ready,14.4%,207) LASER(5,nWait 7,0.0%,269) HEAT(3,nWait 6,0.0%,350) Move(4,nWait 6,0.0%,353) TMC(4,nWait 6,0.8%,99) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,348) MAIN(1,running,83.3%,659) IDLE(0,ready,0.5%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,261), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:00:58 ago, cause: software Last software reset at 2025-02-22 17:15, reason: HeatTaskStuck, Gcodes spinning, available RAM 48832, slot 2 Software reset code 0x0143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0000080f BFAR 0xe000ed38 SP 0x200117d8 Task Move Freestk 1018 ok Stack: 00000000 2001112c 10000000 e000e000 20000f4c 0009f1c5 0009f9b0 61000000 20016de8 20023598 20023598 20023510 00053fd1 00006a74 00000001 00056db3 a5a5a5a5 20023598 20023518 00000000 a5a5a500 4186a760 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 0.7ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 No step interrupt scheduled Driver 0: standstill, SG min 90, r/w errs 0/1, ifcnt 31, reads/writes 3046/14, timeouts 0, DMA errs 0, CC errs 0 Driver 1: standstill, SG min 48, r/w errs 0/1, ifcnt 31, reads/writes 3046/14, timeouts 0, DMA errs 0, CC errs 0 Driver 2: standstill, SG min 2, r/w errs 0/1, ifcnt 31, reads/writes 3045/14, timeouts 0, DMA errs 0, CC errs 0 Driver 3: standstill, SG min 78, r/w errs 0/1, ifcnt 31, reads/writes 3045/14, timeouts 0, DMA errs 0, CC errs 0 Driver 4: standstill, SG min 2, r/w errs 0/1, ifcnt 31, reads/writes 3046/14, timeouts 0, DMA errs 0, CC errs 0 Driver 5: not present Driver 6: not present === DDARing 0 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000803, drives owned 0x00000803 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 11: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Driver 10: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 550, received 2913, lost 0, ignored 0, errs 0, boc 0 Longest wait 3ms for reply type 6061, peak Tx sync delay 186, free buffers 26 (min 25), ts 277/276/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 6.32ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.2.1 Module reset reason: Power up, Vcc 3.41, flash size 2097152, free heap 39348 MAC address f0:08:d1:02:e5:fa IP address 192.168.178.47 Signal strength -39dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-beta.4 (2025-02-11 09:50:58) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: YQ6KF-K096U-D65J0-40KMG-4G03Z-H28XK Used output buffers: 1 of 40 (21 max) === RTOS === Static ram: 94732 Dynamic ram: 97508 of which 0 recycled Never used RAM 49228, free system stack 192 words Tasks: NETWORK(1,ready,11.5%,205) LASER(5,nWait 7,0.0%,269) HEAT(3,nWait 6,0.0%,356) Move(4,nWait 6,0.0%,353) TMC(4,nWait 6,0.8%,103) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,352) MAIN(1,running,85.2%,659) IDLE(0,ready,1.5%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,261), total 100.0% Owned mutexes: === Platform === Last reset 00:00:18 ago, cause: software Last software reset at 2025-02-22 17:17, reason: HeatTaskStuck, Gcodes spinning, available RAM 49012, slot 0 Software reset code 0x0143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0000080f BFAR 0xe000ed38 SP 0x200117d8 Task Move Freestk 1018 ok Stack: 00000000 2001112c 10000000 e000e000 20000f4c 0009f1c5 0009f9b0 61000000 20016de8 20023598 20023598 20023510 00053fd1 0001491c 00000001 00056db3 a5a5a5a5 20023598 20023518 00000000 a5a5a500 418357f0 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 0.7ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 No step interrupt scheduled Driver 0: standstill, SG min 92, r/w errs 0/1, ifcnt 48, reads/writes 933/14, timeouts 0, DMA errs 0, CC errs 0 Driver 1: standstill, SG min 48, r/w errs 0/1, ifcnt 48, reads/writes 933/14, timeouts 0, DMA errs 0, CC errs 0 Driver 2: standstill, SG min 0, r/w errs 0/1, ifcnt 48, reads/writes 932/14, timeouts 0, DMA errs 0, CC errs 0 Driver 3: standstill, SG min 78, r/w errs 0/1, ifcnt 48, reads/writes 932/14, timeouts 0, DMA errs 0, CC errs 0 Driver 4: standstill, SG min 0, r/w errs 0/1, ifcnt 48, reads/writes 933/14, timeouts 0, DMA errs 0, CC errs 0 Driver 5: not present Driver 6: not present === DDARing 0 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000803, drives owned 0x00000803 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 11: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Driver 10: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 199, received 943, lost 0, ignored 0, errs 0, boc 0 Longest wait 3ms for reply type 6061, peak Tx sync delay 6, free buffers 26 (min 25), ts 87/86/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 5.20ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.2.1 Module reset reason: Power up, Vcc 3.42, flash size 2097152, free heap 35904 MAC address f0:08:d1:02:e5:fa IP address 192.168.178.47 Signal strength -41dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-beta.4 (2025-02-11 09:50:58) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: YQ6KF-K096U-D65J0-40KMG-4G03Z-H28XK Used output buffers: 2 of 40 (22 max) === RTOS === Static ram: 94732 Dynamic ram: 97508 of which 0 recycled Never used RAM 49228, free system stack 194 words Tasks: NETWORK(2,nWait 7,11.7%,225) LASER(5,nWait 7,0.0%,269) HEAT(3,nWait 6,0.0%,371) Move(4,nWait 6,0.0%,353) TMC(4,delaying,0.8%,99) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,353) MAIN(1,running,85.2%,659) IDLE(0,ready,1.3%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,255), total 100.0% Owned mutexes: WiFi(NETWORK) === Platform === Last reset 00:00:19 ago, cause: software Last software reset at 2025-02-22 17:17, reason: HeatTaskStuck, Gcodes spinning, available RAM 49012, slot 1 Software reset code 0x0143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0000080f BFAR 0xe000ed38 SP 0x200117d8 Task Move Freestk 1018 ok Stack: 00000000 2001112c 10000000 e000e000 20000f4c 0009f1c5 0009f9b0 61000000 20016de8 20023598 20023598 20023510 00053fd1 00009760 00000001 00056db3 a5a5a5a5 20023598 20023518 00000000 a5a5a500 41836d80 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 0.7ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 No step interrupt scheduled Driver 0: standstill, SG min 92, r/w errs 0/1, ifcnt 65, reads/writes 1016/14, timeouts 0, DMA errs 0, CC errs 0 Driver 1: standstill, SG min 46, r/w errs 0/1, ifcnt 65, reads/writes 1015/14, timeouts 0, DMA errs 0, CC errs 0 Driver 2: standstill, SG min 0, r/w errs 0/1, ifcnt 65, reads/writes 1015/14, timeouts 0, DMA errs 0, CC errs 0 Driver 3: standstill, SG min 78, r/w errs 0/1, ifcnt 65, reads/writes 1015/14, timeouts 0, DMA errs 0, CC errs 0 Driver 4: standstill, SG min 0, r/w errs 0/1, ifcnt 65, reads/writes 1016/14, timeouts 0, DMA errs 0, CC errs 0 Driver 5: not present Driver 6: not present === DDARing 0 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000803, drives owned 0x00000803 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 11: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Driver 10: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 213, received 1029, lost 0, ignored 0, errs 0, boc 0 Longest wait 2ms for reply type 6061, peak Tx sync delay 3, free buffers 26 (min 25), ts 94/93/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 5.17ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.2.1 Module reset reason: Power up, Vcc 3.42, flash size 2097152, free heap 35908 MAC address f0:08:d1:02:e5:fa IP address 192.168.178.47 Signal strength -41dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0and here the Picture of the panel due Console

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

homing the machine causes it to get stuck when attempting to home the Z axis it times out and the wifi module seems to reset, that is atleast what i can see on the panel due that reconnects to the Wifi on timeout

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

the heattaskstuck error where from updating the firmware.

the software reset where from the homing yea.

rolling back to 3.5.4 keeps the homing in working condition -

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@T3P3Tony here is my homeall file

M400 ; Home X, Y, U simultaneously G91 ; Trinamic tuning G1 H2 X0.00625 ; 1 microstep movement to energize steppers G4 P150 ; pause for 150ms G1 H2 Y0.00625 ; 1 microstep movement to energize steppers G4 P150 ; pause for 150ms G1 H2 U-0.00625 ; 1 microstep movement to energize steppers G4 P150 ; pause for 150ms G1 H2 Z0.0000625 ; 1 microstep movement to energize steppers G4 P150 ; pause for 150ms G1 H2 Z20 F2000 ; raise head 10mm to keep it clear of the bed G1 H1 X-99999 Y-99999 U99999 F6000 ; coarse home X, Y and U G1 H2 X4 Y4 U-4 F600 ; move 4mm away from the homing switches G1 H1 X-10 Y-10 U10 ; fine home X, Y and U G1 H1 Z-99999 F6000 ; coarse home Z G1 H2 Z4 F6000 ; move 4mm away from the homing switches G1 H1 Z-10 F600 G90 G1 Z10 F6000 T0 ; Make sure T0 is selected -> ABL Probe ; Now home Z using the Z probe G1 X{155 - sensors.probes[0].offsets[0]} Y{155+sensors.probes[0].offsets[1]} F10000 ; Move to the center of the bed G30 ; probe the bed and set Z height G1 Z10 F3000 ; make sure to clear the bed G1 X{move.axes[0].min+1} F10000 ; Move Toolhead to parking Positionthe issue is not present on 3.5.3

the printer has 2 endstops mounted on Z low to level the gantry when homing

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@T3P3Tony 3.6beta4 still causes the same issue ive had with beta 2.

the Z axis no longer homes and resets the Wifi moduleM122 did not show anything suspicous

=== Diagnostics === RepRapFirmware for Duet 3 Mini 5+ version 3.6.0-beta.4 (2025-02-11 09:50:58) running on Duet 3 Mini5plus WiFi (standalone mode) Board ID: YQ6KF-K096U-D65J0-40KMG-4G03Z-H28XK Used output buffers: 1 of 40 (22 max) === RTOS === Static ram: 94732 Dynamic ram: 97508 of which 0 recycled Never used RAM 49228, free system stack 194 words Tasks: NETWORK(1,nWait 7,14.6%,231) LASER(5,nWait 7,0.0%,269) HEAT(3,nWait 6,0.0%,350) Move(4,nWait 6,0.0%,353) TMC(4,nWait 6,0.8%,99) CanReceiv(6,nWait 1,0.1%,794) CanSender(5,nWait 7,0.0%,336) CanClock(7,delaying,0.0%,348) MAIN(1,running,83.3%,659) IDLE(0,ready,0.3%,29) USBD(3,blocked,0.0%,147) AIN(4,delaying,0.8%,261), total 100.0% Owned mutexes: === Platform === Last reset 00:01:20 ago, cause: software Last software reset at 2025-02-22 15:35, reason: HeatTaskStuck, Gcodes spinning, available RAM 48832, slot 0 Software reset code 0x0143 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0000080f BFAR 0xe000ed38 SP 0x200117d8 Task Move Freestk 1018 ok Stack: 00000000 2001112c 10000000 e000e000 20000f4c 0009f1c5 0009f9b0 61000000 20016de8 20023598 20023598 20023510 00053fd1 00007d02 00000001 00056db3 a5a5a5a5 20023598 20023518 00000000 a5a5a500 41857010 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 a5a5a5a5 === Storage === Free file entries: 20 SD card 0 detected, interface speed: 22.5MBytes/sec SD card longest read time 0.7ms, write time 0.0ms, max retries 0 === Move === Segments created 0, maxWait 0ms, bed comp in use: none, height map offset 0.000, hiccups added 0/0 (0.00/0.00ms), max steps late 0, ebfmin 0.00, ebfmax 0.00 Pos req/act/dcf: 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 0.00/0/0.00 No step interrupt scheduled Driver 0: standstill, SG min 92, r/w errs 0/1, ifcnt 78, reads/writes 4232/14, timeouts 0, DMA errs 0, CC errs 0 Driver 1: standstill, SG min 48, r/w errs 0/1, ifcnt 78, reads/writes 4232/14, timeouts 0, DMA errs 0, CC errs 0 Driver 2: standstill, SG min 0, r/w errs 0/1, ifcnt 78, reads/writes 4231/14, timeouts 0, DMA errs 0, CC errs 0 Driver 3: standstill, SG min 78, r/w errs 0/1, ifcnt 78, reads/writes 4231/14, timeouts 0, DMA errs 0, CC errs 0 Driver 4: standstill, SG min 0, r/w errs 0/1, ifcnt 78, reads/writes 4232/14, timeouts 0, DMA errs 0, CC errs 0 Driver 5: not present Driver 6: not present === DDARing 0 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000803, drives owned 0x00000803 Code queue is empty === DDARing 1 === Scheduled moves 0, completed 0, LaErrors 0, Underruns [0, 0, 0] Segments left 0, axes/extruders owned 0x00000000, drives owned 0x00000000 Code queue is empty === Heat === Bed heaters 0 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0 Heater 1 is on, I-accum = 0.0 === GCodes === Movement locks held by null, null HTTP is idle in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 File2 is idle in state(s) 0 Queue2 is idle in state(s) 0 === Filament sensors === Driver 11: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 Driver 10: no data received, errs: frame 0 parity 0 ovrun 0 pol 0 ovdue 0 === CAN === Messages queued 747, received 4004, lost 0, ignored 0, errs 0, boc 0 Longest wait 3ms for reply type 6061, peak Tx sync delay 182, free buffers 26 (min 25), ts 384/383/0 Tx timeouts 0,0,0,0,0,0 === Network === Slowest loop: 5.20ms; fastest: 0.00ms Responder states: MQTT(0) HTTP(0) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0) HTTP sessions: 1 of 8 === WiFi === Interface state: active Module is connected to access point Failed messages: pending 0, notrdy 0, noresp 0 Firmware version 2.2.1 Module reset reason: Power up, Vcc 3.11, flash size 2097152, free heap 39352 MAC address f0:08:d1:02:e5:fa IP address 192.168.178.47 Signal strength -37dBm, channel 6, mode 802.11n, reconnections 0 Clock register 00002002 Socket states: 0 0 0 0 0 0 0 0havent changed anything on the config from the initial post

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@droftarts is there any update on this?

-

RE: What useful things have you printed on a 3D printer?posted in General Discussion

on my workplace i use FDM Printed parts quite frequently for Workholding Jigs.

either on a CMM or on a Mill to get oddly shaped SLM Printed parts to behave.Printed stuff like a Door Dampener out of 60A TPU to prevent a door to slam shut during the summer months when i have a window open

also for a family member a guideblock for a Circular saw because of poor Manufacturing tolerances the included one had way to much play -

RE: start.g with temperature and print ranges, etc?posted in Gcode meta commands

start.g runs before the slicer gcode.

running a seperate macro at the start of the print called from the slicer and passing in the values is common -

RE: MB6HC 3.5.4 SBC: Show CAN Bus disconnect shorter 2 seconds?posted in Duet Hardware and wiring

the JST ZH connector on the 1LC is a bit finicky.

can recommend to hotglue it in place if you found a position where its happy, also add a strain relief to the CAN cable close to the connector.had similar issues with it in the past, the hotglue fixed it

-

RE: OK, not exactly wiring, but where can I buy wires in US??posted in Duet Hardware and wiring

for cables Igus.com is not bad. its a industry known manufacturer for motion system components. they make quite affordable cables too.

for cimping connectors mouser, digikey, farnell are common places to buy them from.

something to be aware of that a lot of cheap chinese clones have poor tolerances and potentially wont manage the current they are rated for.for your stepper thing, look into Class H stepper they tend to have the wires hardwired to the stepper and take the connector out of the equation.

-

RE: hierarchy of control over gcodes, machine vs filament vs slicerposted in Tuning and tweaking

personally i like to keep as much configurations on the printer itself, has a few benefits in case you loose your slicer configs from a fresh OS install or similar.

also if you run more than one printer with the same build volume you could run sliced gcode for one machine on other machines if you keep the settings on the machine itself.The filament manager is only used if you configure the filaments in there and load them to the tool, personally i use it for PID models (working with materials that have vastly different printing temperatures benefit a bit from a model tuned for the target temperatures) also feedforward is set there for me.

running most settings on the Printer itself also allows you to switch slicers on the fly, sometimes one slicer struggles while a other one does it fine.

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

updating to 3.6.0 kinda borked the entire machine, have to dig into that first.

cant home after the updateHoming resets the wifi module?

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

Updating to 3.5.4 did not Fixed the issue, will try 3.6.0-Beta 2 next

-

RE: Issue with SZP on Secondary Idex Toolheadposted in Duet Hardware and wiring

@droftarts will try to update to 3.6

dont think this will fix the issue you have there, the entire mesh is quite likely applied at the roated state making it not really usefull.

also yea im patient its holiday season so what is a week or two

-

RE: IDEX Extruder Mix Upposted in General Discussion

you have the 2nd tool offset configured in the X axis not U axis. also the mapping for the Axis is missing, you have to map the X axis to be the U axis in line 117

like this (taken from the docs)

M563 P1 D1 H2 X3 F2 ; tool 1 uses extruder 1 and heater 2 and maps X to U, use fan 2 as the print cooling fan G10 P1 Y0 U0 Z0 S0 R0 ; set tool 1 offsets and temperaturesX3 means that X is mapped to the #3 Axis