@dc42 Yes, I am doing that now. However, I want the prompt to contain options that are dynamically created based on the content of "0:/filaments". I don't want to update the prompt every time I add a filament, or modify the name of a filament. Just like how DWC creates the prompt when pressing the 'Load Filament' button.

Posts made by Surgikill

-

RE: Triggering 'Load Filament' prompt with a macroposted in General Discussion

-

RE: Triggering 'Load Filament' prompt with a macroposted in General Discussion

@chrishamm So I'm guessing there is no way I can implement a M291 prompt that pulls variables based on filepaths inside a folder?

-

Filament change logic is not making sense.posted in General Discussion

Hey all,

I'm trying to figure out an issue I am having with filament changes. I'm not sure if this is a new issue, or if I just never noticed this before.

The way I have my duet configured is to use filaments stored on the machine.

I have a load.g, unload.g, and config.g for each filament.

Now, the problems arise when trying to load/unload filament from DWC.

First, if I select the filament from DWC and click 'unload', it heats the bed and waits for the bed to reach temperature first. Is this intended? This is even before it executes M702. This seems counterintuitive. Is this being influenced by tool change macros? When I run T0, it puts the bed into standby mode. However, my toolchange macros don't call for that to happen.

Also, when loading filament, it does not load the selected filament parameters before loading.

For example, if I have PLA loaded, with an active temp of 230, it will unload the PLA, keep the active temp of 230, then when it goes to load PETG it will keep the active temp of 230, even when running M703. I am assuming that this is because the PETG is not 'loaded' yet according to the system. Only AFTER all the macros are done, does running M703 update the temps.

Can anybody explain the logic here and help me figure out a way to get this to work, without needing to manually set temps in a load macro?

Here is load.g

M98 P"0:/macros/Filament/universal_load.g"and here is the 'universal_load.g' macro

M703 M291 R{"Loading " ^ move.extruders[state.currentTool].filament} P"Please insert filament and press OK" S3 M302 P1 ;allow cold extrusion G1 E10 F200 ; Feed 30mm of filament at 200mm/min M302 P0 ;disallow cold extrusion M568 A2 echo "set tool heater to active" M98 P"0:/sys/pause_position.g" var TargetTemp = tools[state.currentTool].active[0] ;set TargetTemp to current tool active temp var thisHeater = tools[state.currentTool].heaters[0] while (heat.heaters[tools[state.currentTool].heaters[0]].current < var.TargetTemp) M291 R"Waiting for temperature to be reached." P{"Current: " ^ heat.heaters[var.thisHeater].current ^ " | Target: " ^ var.TargetTemp} S0 T2 G4 S2 M83 ; Extruder to relative mode G1 E60 F200 ; Feed 60mm of filament at 200mm/min G4 P10 ; Wait 10ms while iterations >= 0 M291 P"Is color correct?" R"Color Change" S4 K{"Yes","No"} if (input == 0) break if (input == 1) G1 E40 F200 ; Feed 40mm of filament at 200mm/min G4 P10 ; Wait 10ms G1 E-1 F1800 ; Retract 1mm of filament at 1800mm/min M400 ; Wait for moves to complete M568 A0 ; Turn tool offunload.g

M98 P"0:/macros/Filament/universal_unload.g"and 'universal_unload.g' macro

;; Universal unload.g - direct all other filament unoad.g instances to this file ;; ;M929 P"0:/macros/filament/unloadeventlog.txt" S3 echo "entering 0:/macros/filament/universal_unload.g" M703 if state.currentTool==-1 M291 R"No Tool" P"No tool selected. Press OK to unload tool 0" S2 T0 P0 if (move.extruders[state.currentTool].filament == "") M291 R"Error" P"No filament loaded. Unload aborted" S2 T2 M99 M98 P"0:/sys/pause_position.g" var TargetTemp = tools[state.currentTool].active[state.currentTool] M568 A2; Heat current tool to active temp G4 S3 var thisHeater = tools[state.currentTool].heaters[0] ;show progress of heating from lower temp while (heat.heaters[tools[state.currentTool].heaters[0]].current < var.TargetTemp) M291 R"Waiting for temperature to be reached." P{"Current: " ^ heat.heaters[var.thisHeater].current ^ " | Target: " ^ var.TargetTemp} S0 T2 G4 S1 M291 R{"Unloading " ^ move.extruders[state.currentTool].filament} P"Retracting..." S0 T5 M98 P"0:/macros/Filament/unload_moves.g" M568 P{state.currentTool} A0 ; Turn current tool offtpost0.g

; tpost0.g ; called after tool 0 has been selected ; ; generated by RepRapFirmware Configuration Tool v3.3.15 on Mon Dec 26 2022 22:40:57 GMT-0500 (Eastern Standard Time) ; Wait for set temperatures to be reached M703 M116 P0 -

RE: Triggering 'Load Filament' prompt with a macroposted in General Discussion

@droftarts If I trigger it using a filament error event, then it's just going to go into the 'filament-error.g' macro, and I end up in the same boat of not being able to get the dialog to pop up on screen with a physical input. It seems like the only way to trigger this dialog is with the button on DWC.

@chrishamm I know I can do it with M291, but that seems pretty clunky, unless there is a way I can extract the filaments by filepath in a subdirectory. I'm not sure of a way to do this.

-

Triggering 'Load Filament' prompt with a macroposted in General Discussion

Hello all,

I am setting up triggers so that I can load/unload filament with physical buttons/filament sensors on my machine. I would like to have it so one of these triggers activates the 'Load Filament' prompt. I have not been able to find anywhere in the documentation if this is possible. Is it only something within DWC?

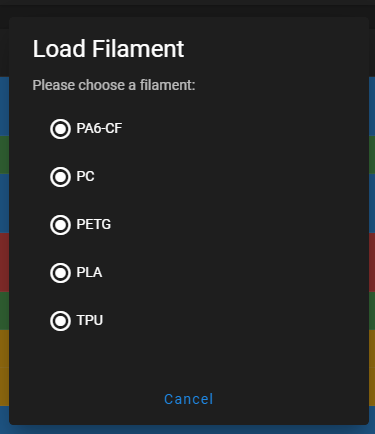

Picture of the prompt I am talking about:

Can anybody help me with this? I know I could create a message with M291, and then select the filaments from there, but that seems to be a very roundabout way of doing it, and I need to make sure that the filaments in the dialog stay synced with the filaments in my filaments directory.

Thank you

-

M581 R-1 behaviorposted in General Discussion

Hi all,

I'm setting up triggers on my duet machine. I have an issue where a trigger may be tripped multiple times, like when inserting filament. This causes messages to be stacked, which is a pain. I am assuming that the way to fix this is to temporarily disable the trigger with the R-1 parameter in M581. The documentation says that "R-1 temporarily disables the trigger". What determines when the trigger is re-enabled? Do I have to recreate the trigger with M581?

Thank you

-

RE: Connecting BTT SFS V2.0 to Duet Toolboard 1LCposted in Duet Hardware and wiring

@droftarts So I got it all set up with triggers and it's working wonderfully. However, I would like to change the way it handles filament loading. Currently, when I put filament into the sensor, it runs my filament load macro. Is there a way I can get it to prompt me which type of filament is loaded, like on the web ui when I select the filament load? I'm not sure how to make that happen.

-

RE: Connecting BTT SFS V2.0 to Duet Toolboard 1LCposted in Duet Hardware and wiring

@droftarts Fantastic. That's exactly what I was thinking of, but I'm not familiar with triggers. I have the pulse sensor already hooked up, and I'm going to tune it now. I will look into the triggers/events afterwards. Thank you.

-

Connecting BTT SFS V2.0 to Duet Toolboard 1LCposted in Duet Hardware and wiring

Hey all,

I just picked up some BTT Smart Filament Sensors V2.0. These sensors have a microswitch for filament detection, and a pulse generating sensor. I want to connect this to a Toolboard 1LC. I'm assuming I can use IO 0, and connect the pulse generating sensor to one of the pins, and then microswitch to the other pin. My question is, how do I setup the firmware to utilize both sensors? I would like to have it so the filament detection switch will run the filament load macro. Has anybody done this before? Can somebody point me in the right direction?

Thank you

-

Best toolhead extruder for flexibles?posted in General Discussion

Hi all,

I'm still working on the design of my toolchanger. One of my big issues has been finding a good extruder for the system. I was planning on going with the smart orbiter V3.0, but now I am having second thoughts. My initial thought was to go with the hemera xs, but the price point of the hemera xs and revo nozzles is too high, considering I will need to be making multiple toolheads. I was also considering the biqu toolhead, but I'm not sure on quality.

The main issue is that these must print flexibles. This is why I have been looking at hotend/extruder integrated combos pretty much exclusively.

Can anybody give me any input here? Currently I print with 2 hemeras, and they handle flexibles wonderfully.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@Surgikill said in Duet3D announces new tool board at FormNext:

@Exerqtor I'm still waiting on more tests. My money is on the stealthchop issue. Apparently around 300rpm is where the problem arises. I'll do some quick math to see if that is around the 8mm/s where he was experiencing drop off.

At 300rpm on the motor, the hobbed gear would need to be around 18mm in order to achieve 8mm/s. At 10mm/s it would need to be around 23mm. I'm not sure on the actual size, but I would bet all my money it's less than 18mm, so that motor was going well in excess of 300rpm. Definitely needs more testing.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@Exerqtor I'm still waiting on more tests. My money is on the stealthchop issue. Apparently around 300rpm is where the problem arises. I'll do some quick math to see if that is around the 8mm/s where he was experiencing drop off.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@jay_s_uk said in Duet3D announces new tool board at FormNext:

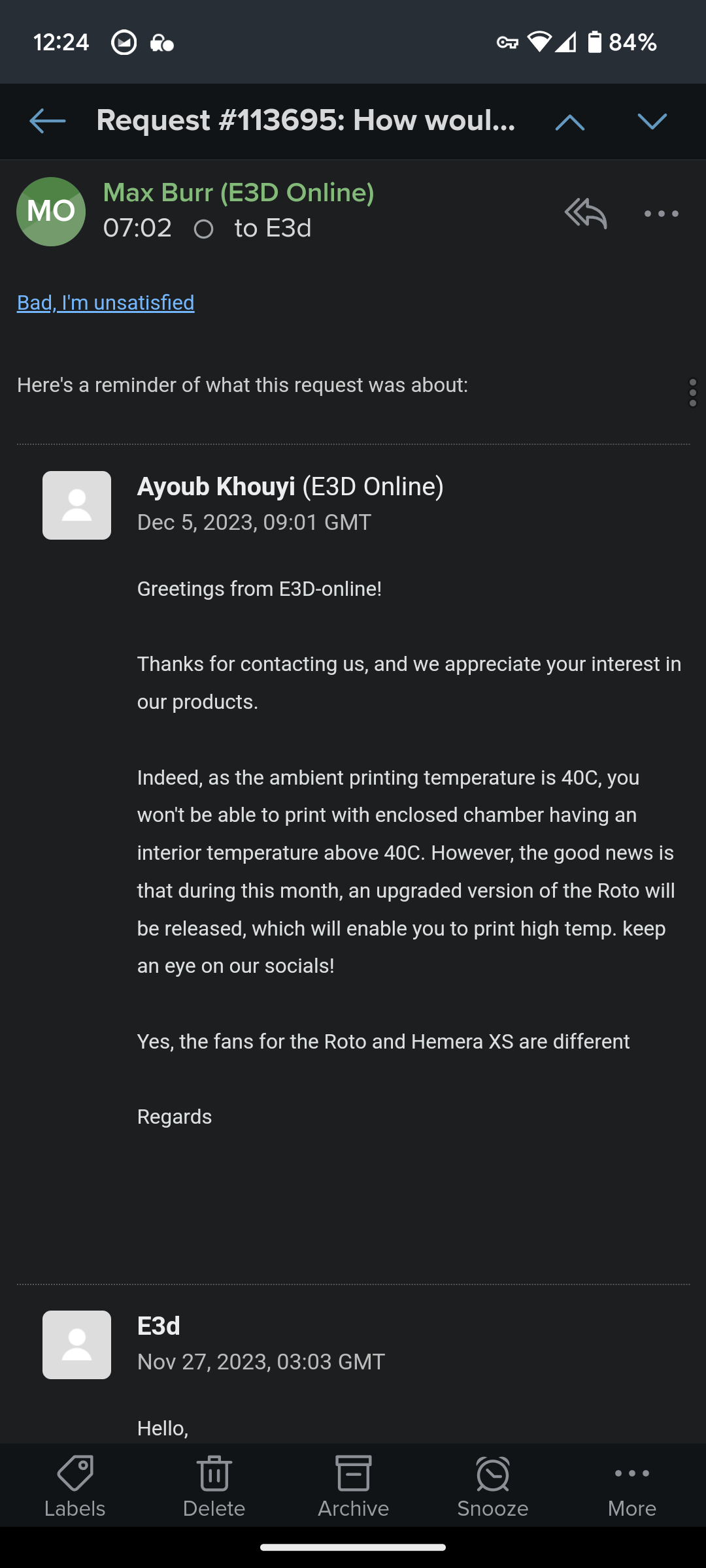

@Surgikill I spoke to E3D about this today. The limitation on the 40 degrees is the motor, nothing else. They will releasing a more capable motor in the new year

Just to corroborate this, I received this response from e3d today. Hopefully the ht version does release this month.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@jay_s_uk Awesome. Thanks for the heads up. I submitted a support request but haven't heard anything back.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@deckingman from the video interview they did they said that this heatsink is the most efficient heatsink they have ever designed, but that doesn't mean it can wick away more heat.

I'm hoping that the limit is pla printing, but I kind of doubt it. I might be able to get away with 40c chamber temp, but would much rather run at 65. Guess I will just have to use the hemera xs.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@sebkritikel Awesome, thanks for the info. The LDO pancake does use class H insulation from the datasheet. What I am wondering is if the E3D motor could be replaced with the LDO to raise the ambient operating temp of the system to >40C. The Roto motor seems to be different from the LDO (Max current of 0.6A vs 1.0). It appears the spur gear on the stepper may be different.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

Anybody have any idea why the motor on the roto is only rated for 50C? Looking at the 36mm LDO pancake stepper, it is rated at 180C. Not sure how accurate that is, but it is a gulf between the roto and the LDO, and they look like the same motor.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@elmoret if that's the case then it's a different story, but if the motor is only rated to 50c then I don't see it going over that, which is still pretty low.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

@jay_s_uk yes, that is where I got the info. I know in the interview they said this heatssink is the most efficienct they have ever designed, going as far to say they printed pla at 40c ambient temp. I'm not sure if this is why it's rated at 40c, or if it's the plastic planetary gears.

-

RE: Duet3D announces new tool board at FormNextposted in General Discussion

Eh, I just found some basic documentation and max ambient printing temp is 40C. Think I'm going to have to pass on this extruder.