Duet3D announces new tool board at FormNext

-

@edsped I've found even for one tool head, I'd trade the cost for the convenience of not having to run 19 conductors for each tool.

- heater: 2

- thermistor: 2

- fan: 3

- fan: 4

- stepper: 4

- filament sensor/(un)load trigger button: 4

-

Anybody have any idea why the motor on the roto is only rated for 50C? Looking at the 36mm LDO pancake stepper, it is rated at 180C. Not sure how accurate that is, but it is a gulf between the roto and the LDO, and they look like the same motor.

-

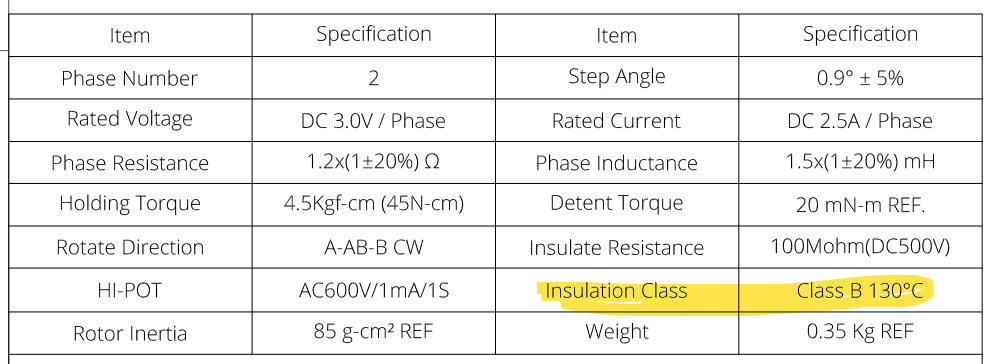

@Surgikill Most stepper motors used by 3D printing enthusiasts are built using 'Class B' insulation for the motor windings. For 'Class B', the max allowable winding insulation temperature is 130°C, which often yields a max motor ambient temperature of 40-50°C (not stepper casement temperature).

http://www.drivesandautomation.co.uk/useful-information/nema-insulation-classes/

Example motor with specs on insulation, thermal rise, etc

https://catalog.orientalmotor.com/item/2-phase-bipolar-stepper-motors/42mm-pkp-series-2-phase-bipolar-stepper-motors/pkp244d08a2Most of us skirt by this 'max temperature' limitation by running steppers at 85% or so of the rated current, that gives some margin for an elevated ambient temperature. Running with an ambient temperature higher than the spec'd motor ambient could result in reduce service life for the motor. Ends up most of us ignore what 'Class B' insulation means, or simply don't know (I have been ignoring it, been running ambients in the 60-70°C on my motors

)

)Without looking at a datasheet... the roto motor likely has 'Class B' insulation.

Speaking of datasheets, a lot of steppers used in printers seen here don't go into the detail manufacturer's like Oriental Motor use on their datasheets (example snippet from a popular stepper seen here):

If you read the specs above, and don't further research what 'Class B' means, you might assume the motor running at 130°C is fine... and by running at 130°C, one might think thats the easily observable casement temperature (they do get hot!).

With extruder motors, its often recommended to run them at a significantly reduced current (at least when they were using smaller NEMA17 motors) for two reasons:

- The torque at full current was much greater than what was needed for extrusion force

- The casement thermal rise at full (or 85%) current could soften the filament, depending on how the filament drive was connected to the stepper)

Its possible that, while the roto motor uses 'Class B' insulation, it doesn't need to run at rated current, meaning theres higher margin for ambient temperature (maybe, a good amount of conjecture on my part of the requirements of the roto motor

)

)As far as that LDO pancake stepper, LDO has been making a series of high temperature motors for the enthusiast community using higher rated winding insulation.

-

@sebkritikel Awesome, thanks for the info. The LDO pancake does use class H insulation from the datasheet. What I am wondering is if the E3D motor could be replaced with the LDO to raise the ambient operating temp of the system to >40C. The Roto motor seems to be different from the LDO (Max current of 0.6A vs 1.0). It appears the spur gear on the stepper may be different.

-

@dc42 Is the Roto toolboard going to be compatible with the existing tool distribution board? Will there be an updated distro board with the new connector? Is there the possibility for an updated 1LC with the new connector?

-

@curieos you can use the Roto tool board with the existing tool distribution board (TDB) like this:

If the cable length from the TDB to the TOOL1RR is no more than 1m:

- Connect the Roto CAN wires to just two of the pins on the 4-pin connector on the TDB

- Install the bypass jumpers for that port on the TDB

If it's more than 1m:

- Don't install the bypass jumpers for that port on the TDB

- Run 2 twisted pairs from the 4-pin connector on the TDB to a junction point no more than 1m from the TOOL1RR, then use the TOOL1RR cable to connect the ROOL1RR to that junction.

In time we are likely to produce a new TDB with more connection options.

-

@Surgikill the trouble with letting the motor get hotter is that it will result in the gearbox temperatures being exceeded - not a simple change to make, or I’m sure they’d have done it. 180C windings are also more expensive, and of no benefit to 95% of users.

Maybe a HT version in the future, with 180C windings and an uprated gearbox… but then the fan’s the limit. So water cooling? And round and round you go, building a product for an increasingly small customer set.

-

@elmoret said in Duet3D announces new tool board at FormNext:

@Surgikill the trouble with letting the motor get hotter is that it will result in the gearbox temperatures being exceeded - not a simple change to make, or I’m sure they’d have done it. 180C windings are also more expensive, and of no benefit to 95% of users.

Maybe a HT version in the future, with 180C windings and an uprated gearbox… but then the fan’s the limit. So water cooling? And round and round you go, building a product for an increasingly small customer set.

And as you said above, the temperature limit could be based on printing PLA without jamming. That might be down to the efficiency of the heat break. If so, then when you get up to circa 80 Deg ambient, other filaments might start to jam too. From what I've been told, most electronic components will have a shorter life when subjected to higher temperatures so it may be the case that users might have accept a much shorter service life and replace the boards every year or so. All in all, it might just be better to enclose the print head from the heat break upwards in some sort of box and pump cool ambient air into it. A bit of a pain to do but it might work out cheaper in the long run.

-

@deckingman from the video interview they did they said that this heatsink is the most efficient heatsink they have ever designed, but that doesn't mean it can wick away more heat.

I'm hoping that the limit is pla printing, but I kind of doubt it. I might be able to get away with 40c chamber temp, but would much rather run at 65. Guess I will just have to use the hemera xs.

-

@Surgikill I spoke to E3D about this today. The limitation on the 40 degrees is the motor, nothing else. They will releasing a more capable motor in the new year

-

@jay_s_uk Awesome. Thanks for the heads up. I submitted a support request but haven't heard anything back.

-

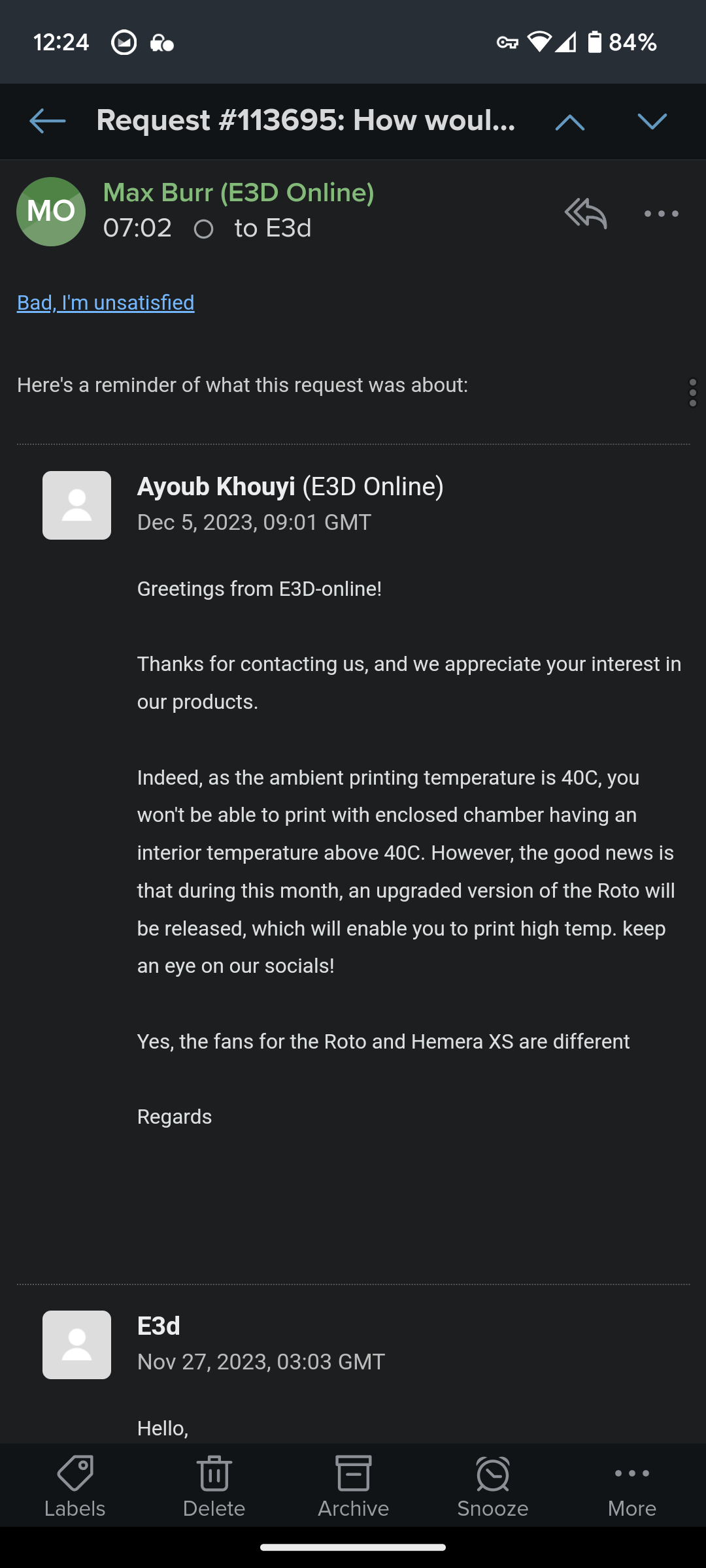

@jay_s_uk said in Duet3D announces new tool board at FormNext:

@Surgikill I spoke to E3D about this today. The limitation on the 40 degrees is the motor, nothing else. They will releasing a more capable motor in the new year

Just to corroborate this, I received this response from e3d today. Hopefully the ht version does release this month.

-

This make you wonder why they (E3D) released a product only to advise they are going to update it a few weeks later, i wonder if early adopters with get an upgrade ?

-

@Mr-Crispin said in Duet3D announces new tool board at FormNext:

This make you wonder why they (E3D) released a product only to advise they are going to update it a few weeks later, i wonder if early adopters with get an upgrade ?

I think you/we/many are overthinking what most/many use their 3D printers for. Most people using their 3D printer for hobby stuff without an enclosure will probably newer have an issue with a 40C rated DD extruder, since they're probably pushing PLA or PET with it anyways.

And those of us with enclosued printers pushing ABS, ASA etc. will just have to wait. A larger "issue/challenge" is the torque/accelerantion dropoff the Roto apparently has (based on Thomas Sanladerer's video).

-

Also lets not forget about E3D's design methodology of under promise over deliver.

The reason for the 40C recommended limit is going to be a worst case scenario style of limit. where you are running the extruder at max power, on a high flow hot end, on the largest nozzle, in higher than ambient temperatures, with a low temp filament.

-

@Exerqtor said in Duet3D announces new tool board at FormNext:

And those of us with enclosued printers pushing ABS, ASA etc. will just have to wait. A larger "issue/challenge" is the torque/accelerantion dropoff the Roto apparently has (based on Thomas Sanladerer's video).

There is speculation in the comments (which Tom hadn't denied when I looked yesterday) that the dropoff at high extrusion rates was caused at least in part by running the extruder in stealthChop mode.

-

@Exerqtor I'm still waiting on more tests. My money is on the stealthchop issue. Apparently around 300rpm is where the problem arises. I'll do some quick math to see if that is around the 8mm/s where he was experiencing drop off.

-

@dc42 I cant say for certain as I have only tested the preproduction version. But I definitely didn't get the same values as Tom

-

@Surgikill said in Duet3D announces new tool board at FormNext:

@Exerqtor I'm still waiting on more tests. My money is on the stealthchop issue. Apparently around 300rpm is where the problem arises. I'll do some quick math to see if that is around the 8mm/s where he was experiencing drop off.

At 300rpm on the motor, the hobbed gear would need to be around 18mm in order to achieve 8mm/s. At 10mm/s it would need to be around 23mm. I'm not sure on the actual size, but I would bet all my money it's less than 18mm, so that motor was going well in excess of 300rpm. Definitely needs more testing.

-

Is there any access to the printed mount parts for the Z sensor? I've seen the spacer for the tb but nothing else.