Ugggh, so this is weird. I updated the firmware thinking it could have been a firmware issue (long shot, I know).

M997 B20

After waiting many miinutes with no response, I power cycled.

'

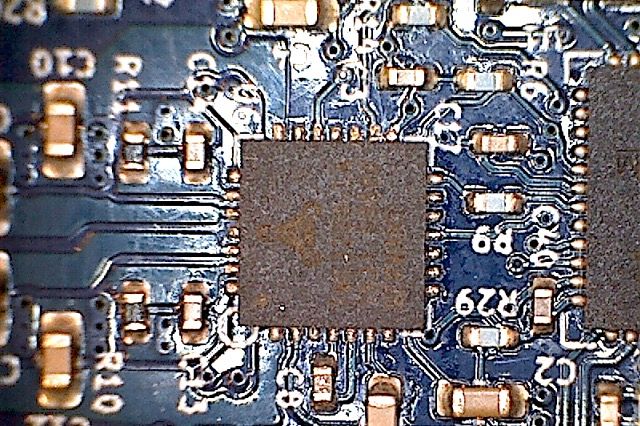

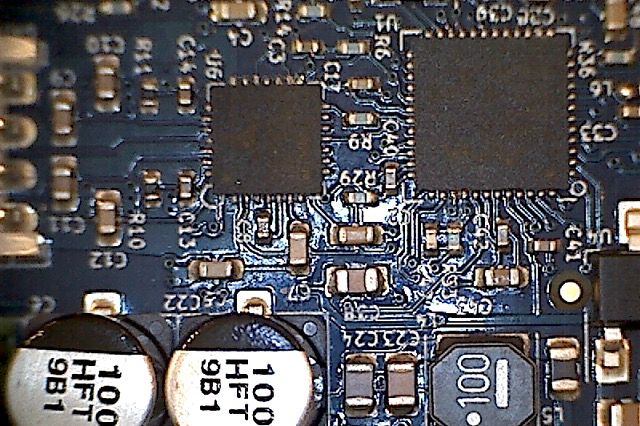

Now the Duet3 isn't communicating with my Toolboard - tons of CAN response timeouts. No slow red flash, just the solid blue and solid red leds. The heater and fan turned on (I see the warning about that in the docs), so i removed all connections to the board except CAN and power and stepper.

I tried a double button power on to reset.

M115 B121 (or 10 or 20, the address i previously programmed) also error.

M409 K"boards" yields this:

{"key":"boards","flags":"","result":[{"canAddress":0,"firmwareDate":"2020-03-16b1","firmwareFileName":"Duet3Firmware_MB6HC.bin","firmwareName":"RepRapFirmware for Duet 3 MB6HC","firmwareVersion":"3.01-RC4","iapFileNameSBC":"Duet3_SBCiap_MB6HC.bin","iapFileNameSD":"Duet3_SDiap_MB6HC.bin","mcuTemp":{"current":29.4,"max":29.5,"min":18.3},"name":"Duet 3 MB6HC","shortName":"MB6HC","supports12864":false,"v12":{"current":12.2,"max":12.3,"min":12.2},"vIn":{"current":23.9,"max":24.0,"min":23.9}}]}

Seems the bootloader got corrupted.

Is there a bossa solution to reprogram the bootloader on a Toolboard?