I know this is an old thread, but thought I'd drop my experiences in here.

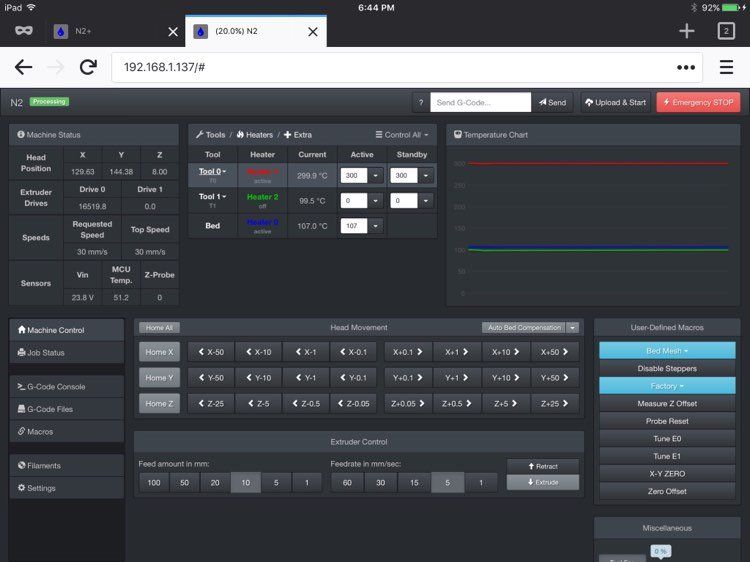

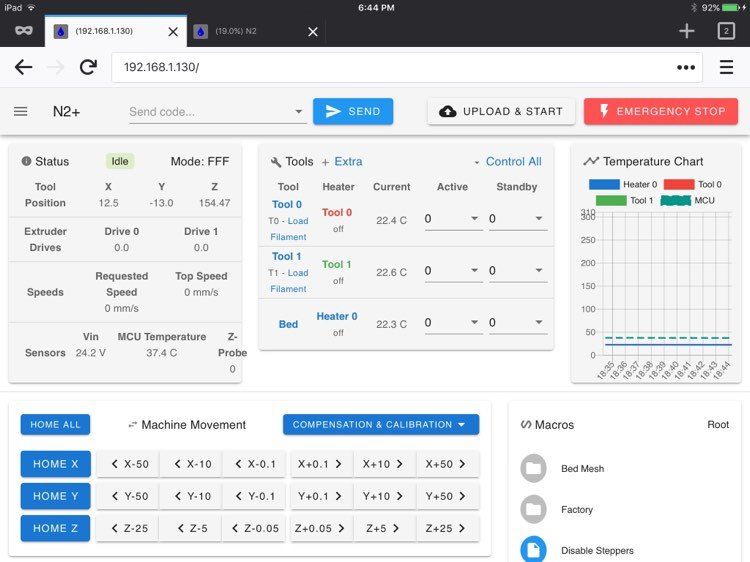

I converted a Raise3D N2 and N2+ to Duet2 Wifi. I used a PT100 board for the bed heater, and the Raise printers use type K thermocouples in the print head.

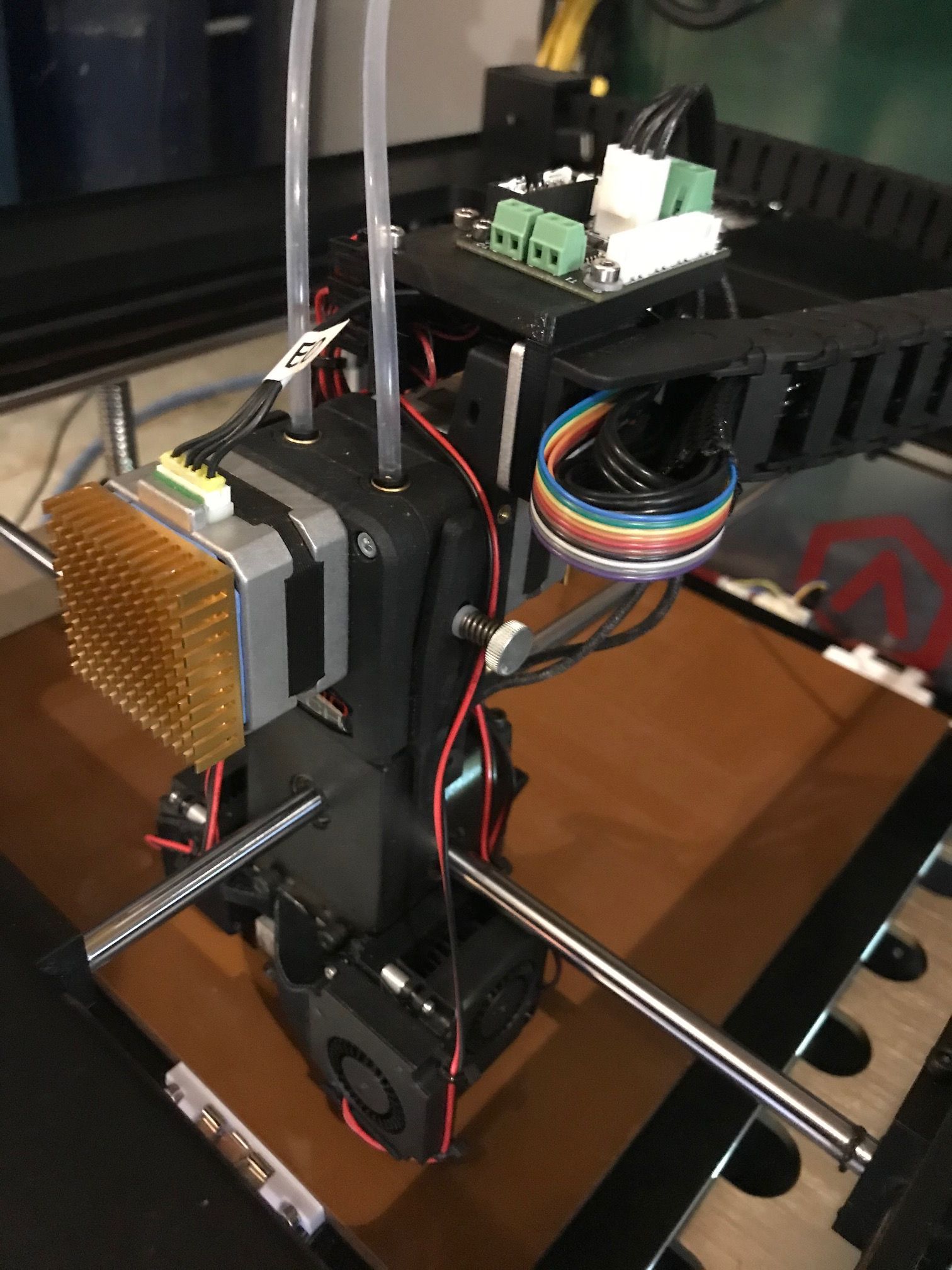

I did not know there was an issue mounting the thermocouple board remote. I used 26ga ribbon cable and 10 pin ribbon cable connectors to make an extension cord. The PT100 board is on the Duet board. I mounted the thermocouple board up on the print head.

On the smaller N2 the ribbon cable is roughly 1.5M long. It's been running fine since June. At one point I had an issue with a thermocouple reporting 2000 degrees - I replaced the thermocouple and the error went away. The thermocouple did not appear to be bad when it was off the machine.

The larger N2+ has almost 2M of ribbon cable to the thermocouple board. I had persistent issues on that machine with the thermocouples faulting on power up and reporting 2000 degrees. I swapped some thermocouples around and got it so E0 was reporting OK, but not E1. Poking around the forum at that point was when I learned I had done everything wrong.

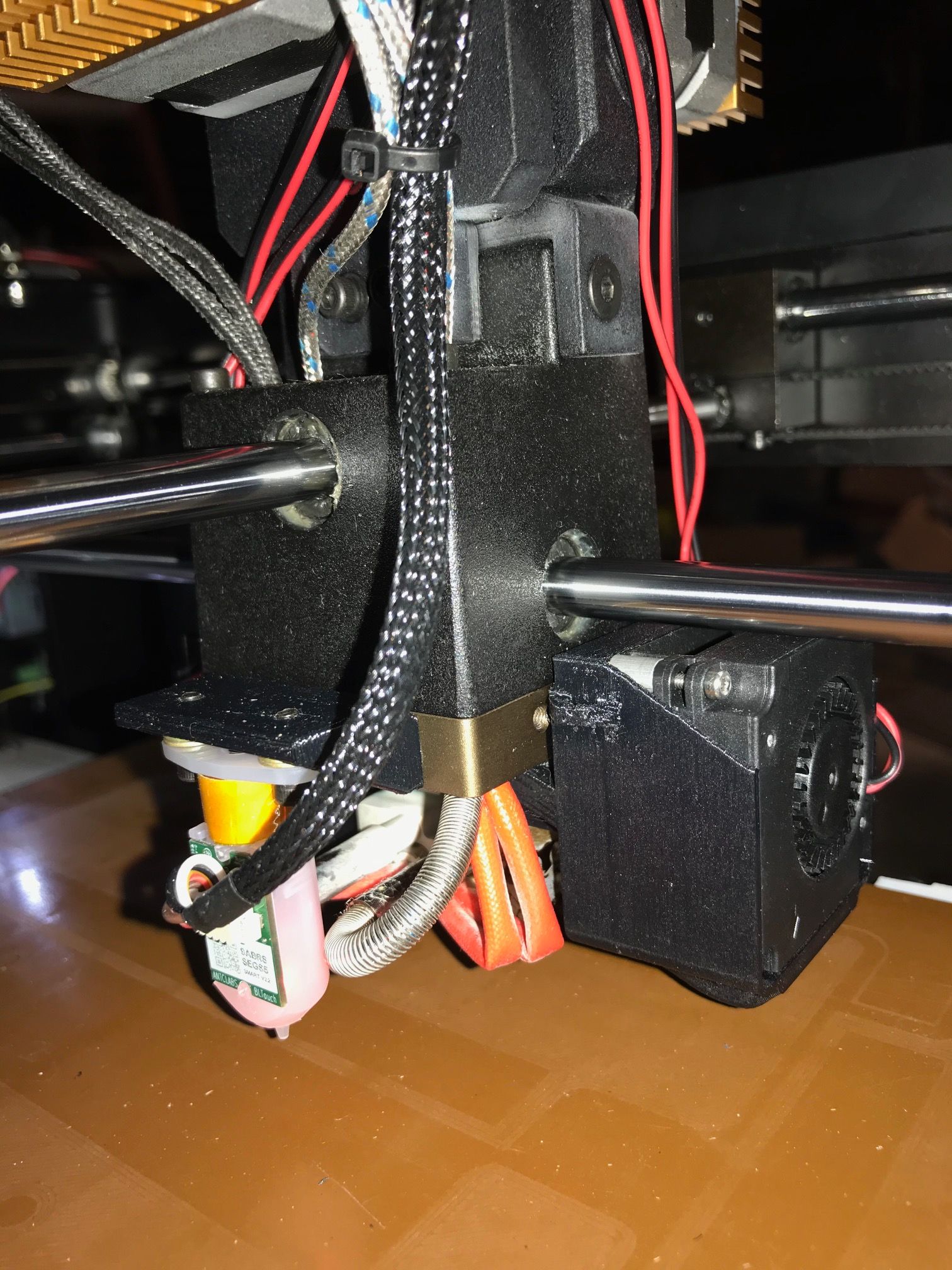

On the N2+ I moved the thermocouple board down to the control board and ran shielded, twisted, type K thermocouple wire up to the print head. That did not resolve the startup fault problems - but the machine was working and I had work to do.

I purchased more thermocouple wire so I could rewire the N2 if it started giving trouble. I haven't had the need.

After 6 months or so of heavy use, the N2+ started getting temperature spikes on E0 and faulting. I tried a different thermocouple, but that did not resolve the spikes. The thermocouple extension wire is foil shielded, so it may be that the foil split in the flex to the print head. Just speculation.

Since the smaller N2 has worked great for 9 months or so, I decided to try reverting the N2+ to the ribbon cable extension, knowing that it's not supposed to work.

When I got the ribbon cable re-routed and powered up the printer last night, the thermocouple that had been faulting reported 2000 degrees. I replaced it and that seemed to make things happy.

I've now been printing straight for about 24 hours and haven't seen a temperature spike.

I don't know enough about this sort of thing to make any claim about right or wrong, but it's working for me. I know I might just be lucky. (I don't usually consider myself lucky)