How many tools?

-

@engikeneer said in How many tools?:

The hardest part of setting up my toolboards was having to solder sleeve tiny ZH pigtails onto the CAN lines

I find it easy using white solder sleeves like these https://www.amazon.co.uk/Connectors-Soldering-Connector-Waterproof-Electrical/dp/B0DK18MJHG with a hot air gun. I generally poke one of the wires in the correct distance, then heat just the glue ring of the sleeve around that wire to capture it. Then do the same with the other wire. Then heat the solder part in the middle.

However, I've had a few instances of pre-made ZH connectors with wire tails having bad crimps; so that is another reason to use something different. The XT30 2+2 connectors are great if both ends are pre-made, but a pain to solder otherwise.

-

@dc42 yeah thats exactly what I did (was following your blog post actually which was helpful!)

After doing 64 of them, making sure each of the pairs were soldered at the same length, with a reasonable twist left and didn't bunch up in an awkward place in the tool support, I got pretty good, but had burnt my fingers more times than i can count. At a typical labour rate, those cables would have cost more that all the Duet boards on the printer with how long I spent on them!

Having said that, the printer is much neater and better setup with the CAN boards. Being able to pull a complete tool off the printer by only pulling out 2 plugs and a couple of screws has been very handy at times. I certainly wouldn't go back to non-CAN in the future, but I would spend a fair amount of time (and money) to try and avoid the solder sleeves if it was building a new printer again. -

@Notepad said in How many tools?:

XT30

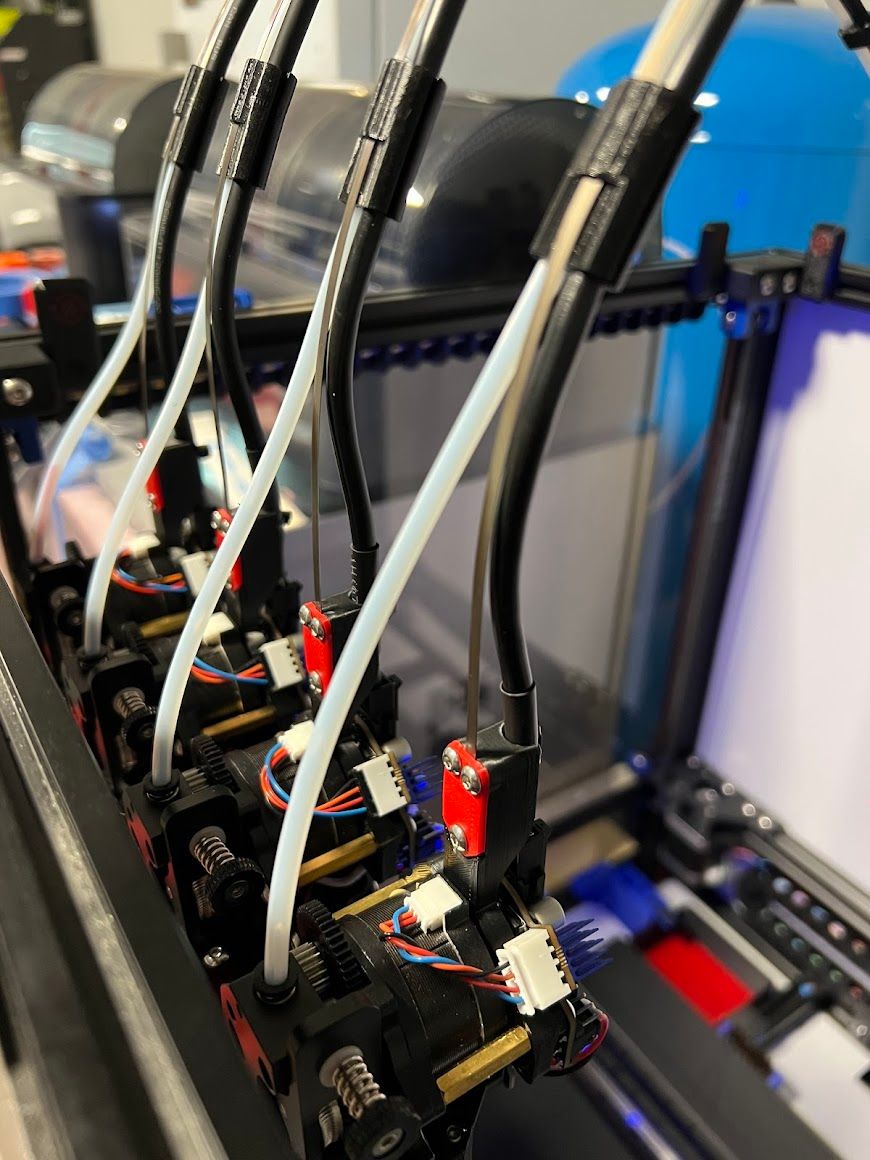

Just embarking on a toolc hanging setup on my Voron 2.4r2. Going with Stealthchanger. Most of the folks fully engaged in this endeavor are at minimum of 4 toolheads, and many have 5 or 6 - currently watching a V2.4 350mm build with 6 ANTHEAD toolhead possibly seven.

Seems 4 would be a minimum, 6 seems like a sweet spot. BLUE stuff isnt mine

Rookie red stuff is ...

Rookie red stuff is ...

-

minimum of four tools for tool changer just seems to be an evolutionary inevitability to me. For two tools, IDEX is much easier to build and use (and you can make tool changes in less than two seconds with careful tuning). For three toolheads, its just not worth the added complexity and cost of machine space so four is the viable minimum and six/seven the viable maximum without enlarging the machine just to get more docking area ...

(yes, you can get a PrusaXL with one or two tools, but thats a business consideration).

-

@T3P3Tony USB connectors would be nice option for CAN and Power transfer.

-

@Aurimas IMO USB connectors are a terrible choice because someone will plug the wrong wires with rhe right connector in and then things will go splooey.

Also USB connections arent specced for motion, so having them on a toolboard invites them getting loose over time.

-

@oliof pretty much all others use them. I use them with my custom setup too and it works great.

-

@Aurimas whats wrong with the XT30 2+2 connect thats been adopted widely by the hobbyist market? AFAIK USB connectors are limited to 5A. No good for high powered tools etc

-

@Aurimas

No no USB is a horrible choice. The connectors are far to big and have my downsides for our usecase. And you need to use other wires anyway, the USB cables do not last long in chains.

Everything is better than this USB connectors. -

@jay_s_uk The XT30 2+x are nice, but that is the idea to get CAN out of the board than? A other connector? Solder pats?

-

@T3P3Tony I akes a while ago for a toolboard with more than one stepper connector too. That would help a lot when you build things like Enraged Rabbit or if you want to power a gantry with a can board.

To be honest: I would love to see more smaller and specialized tool boards.

Why not having a toolbaord which is specialized for a chamber heater? Just some outputs for SSRs and some temp sensors plus a servo?

Why not a board with 2 or 4 stepper drivers and 4-6 I/Os for endstops? (For gantries in a corexy)Or an toolboard just to control RGB Leds. And why not one like a daughter board which you can be stacked on the toolboard for the head?

And what is about a can multiplexer board? It would be nice to have more than 1 can bus in the system to make it more flexible. The stup setup is not ideal, you hit the 1m limit very easy.

I think that it is easy to come to more idea for boards which are dedicated to a very special usecase.

Cheers, Chriss

-

@Chriss said in How many tools?:

@jay_s_uk The XT30 2+x are nice, but that is the idea to get CAN out of the board than? A other connector? Solder pats?

The EXT30 2+2 are used as stubs normally.

-

@Chriss regardless how long they last - they are cheap, neat and super easy to replace.

Instead of running bunch of cables and having no quick disconnect option one cable is simpler.

Connectors big? Not sure where you got that -

@Aurimas When was the last time you replaced a USB-C connector on a pcb? I guess not once, you would not call it super easy to replace if you did it.

Have you ever compared a USB-C connector with a XT30 2x2? They are far bigger. And have you ever seen a plug where you can solder the wires in? Or crimp them? Many users use cables which are certified for drag chains, one of the USB cables I found are.

Do do you plan to consume 10A over a USB connector?

How to you build cables with custom length?And almost every USB-C connector to solder on a PCB has a higher price tag than a XT30 2x2 connector. Every XT30 2x2 plug has a lower price than a USB-C cable. What are you talking about?

And how do you explain the weakness at the soldering point when you solder drag chain compatible wires at the cable coming out of the USB-Connector?

Cheers, Chriss

-

For me 8 tools is probably the maximum that would be practical in terms of space/cost - so I'm quite happy with 4 tools on distribution boards that can be chained together, or a single new board with 8 connectors.

Ideally as you mentioned with something bigger than the existing 1.25mm FD connectors.

For the tool boards themselves, a smaller footprint would be nice.

Perhaps having the connectors vertical would save some space.

Plus at least one additional part cooling fan connector, and the option to add a second stepper driver would be perfect.

-

@Chriss well guess again - I have done fair few of them. no need to be patronising because some other people might have done a lot more than you.

-

@Aurimas Cool, so we agree that not everybody can solder 0,25mm² on a usb connector, the connector can not handle more than 5A and it is a very big chunk of metal/plastic.

And nobody came out with any benefit the connector comes with, using per-configured cables from a reseller is nothing I can see on the positive site at all.