Vertical lines vs. geared extruders

-

@hackinistrator Interesting video. I suppose we have to wait for the second video to find out why this is caused by what he says it is? I was watching with captions on and no sound, so maybe I missed some type of evidence that was presented?

Not an attack. The theory seems quite plausible, I'm just genuinely curious as to if any more info is out there or in the video that I missed.

-

@hackinistrator said in Vertical lines vs. geared extruders:

this guy is doing great analysis of this issue

https://www.youtube.com/watch?v=dL6u0UwPJOQit looks like he also thinks (like me) that this comes from direct drive dual gear extruders . i'm waiting for the next vid to see his conclusion .

Wow.

He has done an amazing amount work - interesting stuff - this shows that being obsessed can be a good thing - at least for the rest of us.

I'm currently only using Zesty Nimble v1.x remote drive extruders, with a variety of hot ends, and I am quite happy with the results.

Sometimes I get faint diagonal lines but to see them I need a flashlight has he has done.

Be interested to see if he finds the "ultimate" solution to this problem.

I'm waiting on v3 of the Nimble which is supposed to deal with the diagonal lines - only time will tell.

Frederick

-

@hackinistrator I printed the slanted recommended test print and I see the wood pattern! I also have a bondtech dual drive wheel setup.

My theory would be that it is a slight non-concentricity of the drive wheel. However, the YouTuber suggests that turning one of the wheels around so the gears don't mesh resolves the issue. This seems odd to me, because the gears on my machine are not closely meshed. There is a LOT of movement before the gear teeth touch. I would have thought this basically removed their influence from anything, unless the filament grinded or something and the wheel slipped and had to turn the other one, instead of the other one merely idling along.

I digress. I'm interested to see this next video! I wonder if grinding off the gear teeth from the bondtech wheels would help. I have never felt the gears were beneficial. I just liked having two toothed drive gears. IMO, the idler is a difficult part to source otherwise. Plain bearing? Meh. I'm just rambling.

-

@bot The follow up video is now available

-

@skrotz Yes I saw that. I agree with the conclusion that the "wood grain" pattern is being caused by the gear teeth meshing. I'm gonna grind mine off and see if it makes extrusion smoother.

-

Interesting videos. New gear design required. I had the thought of using two motors to drive in unison but that comes with it's own issues.

-

I guess I don't feel so out of date for still running a single gear titan aero like a pleeb.

-

I have tried a few of the test prints from the videos. I have been unable to get the “wood grain” pattern to show up with an LGX extruder(pleased about that).

I’m going to try a few different parameters to see if I can excite it in some way because it’s a dual drive and I would expect similar results in some form or fashion.

-

I just printed "rectangular 2 recommended.stl" using recommended settings and reported my results with photos through the survey page linked in the video description. I have a genuine Bondtech BMG suspended with a 140mm bowden on my delta and I see no such artifacts. Perhaps I got lucky with my BMG unit or maybe the bowden is long enough to compensate (though my usual retraction is under 2mm).

Perhaps this is an issue of stacking tolerances leading to problems in some setups. -

@alex-cr

the LGX is the one with the bigger diameter gears?

I suspect they made them bigger, also to have better bearings for the gears.

The usual barrel bearing and the super small main bearings might have an influence on the lack off smoothness of extrusion, too? -

@ajdtreyd

bowden wont show those problems , it is masking it .its a combination of things , bondtech style drive + short filament path .

i have V6 style heatsink that was cut in half (to shorten filament path) , after cutting the pattern or "inconsistent extrusion" became much worse . -

@hackinistrator

that would explain, why my old Prusa I3 had such terrible ringing (I thought it was ringing). The heaterblock was mounted right below the extruder and the drive gear was just a fine-pitched pinion gear.

I tried to tighten the belts, but made no difference -

I said it was a cogging issue with the spur gear teeth at the beginning of this thread, and suggested herringbone gears! However, the problem isn't the gears not meshing (the second one just becomes an idler), it's when there's too much pressure on the gears, ie the idler pressure is done up too tight, so they bind on each tooth. All straight cut gears have this issue; they are not meant to be pushed hard into each other.

It would be interesting to print the trapezoid shape while reducing the idler pressure by half a turn every 1cm of height, between maximum pressure and when the filament slips. Might show that there is an optimum pressure to avoid the issue, while still having good grip.

Ian

-

Just printed the 'rectangular 2' with a Bondtech BMG (BMG-M w/Mosquito, to be precise) - its very, very faint, but the wood pattern is there.

FWIW the most consistent outer wall (smoothest) prints I've personally seen come from the Stratasys 1200 series printers with the closed loop Maxon DC motors (excluding all other wall artifacts).

-

@droftarts said in Vertical lines vs. geared extruders:

I said it was a cogging issue with the spur gear teeth at the beginning of this thread, and suggested herringbone gears!

I thought that sounded familiar.

-

Hmmm. One of the reasons I switched to the BMG from stock was because my prints exhibited the woodgrain pattern. The BMG ended that. The stock extruder was a single gear drive. Before I moved the BMG to a flying extruder mount it used the stock mount at the end of a 750mm bowden tube.

-

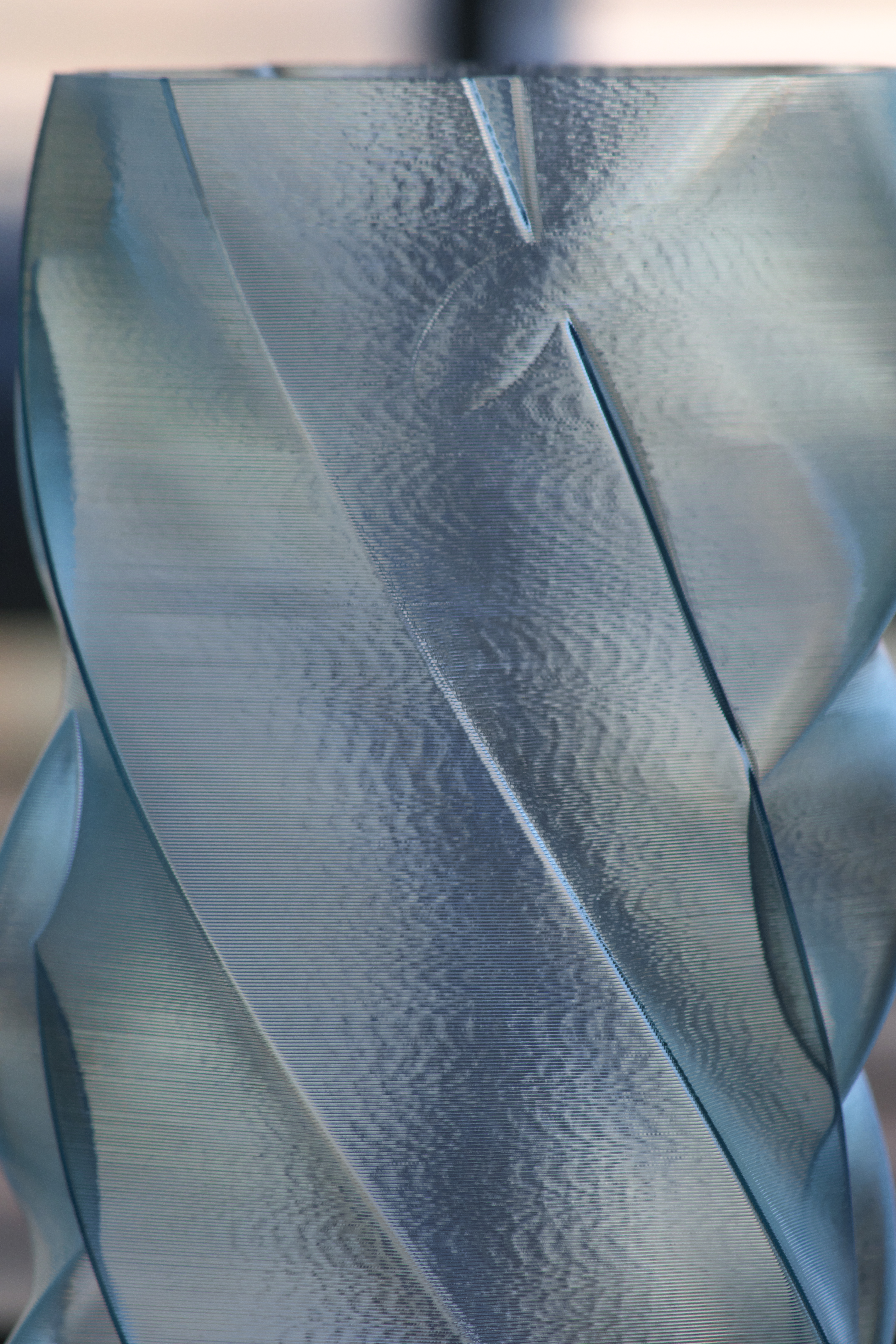

Here's a single walled vase, PETG, 1.2mm line width, 0.6mm layers, Bondtech BMG extruder:

-

@mrehorstdmd that's a

paddlin'woodgrain. -

@alex-cr I have simple parallel vertical lines (not what I'd call wood grain) on my Railcore, but I'm still wondering. It's not ringing, because it's all the way across a side. I've replaced just about the entire hot end, including the Bondtech with another identical one I had. In the entire hot end and moving parts, the only parts I haven't replaced are: the heat sink in the hot end; the belt; the linear rails and carriages. Every change has either had no effect, or made the artifact print all the more clearly (unmasking it some, perhaps).

The other oddity is that it can be improved a fair amount by printing perimeters at break-neck speed. I lowered jerk a LOT and lowered acceleration some to keep the corners from getting bad. Faster speed should not make a motion artifact better. Looking at microscopic images, the extrusion looks like a very nice sine wave of narrower and wider, with a regular period. I know that could be motion but then I'd expect it to vary depending on which stepper/belt was more active in a particular movement direction, which it doesn't. So it looks to me like variation in extrusion.

The reservation I have about "extruder design" is that this is a fairly new problem to me, but I've had the BondTech extruder since day 1. So what changed? Not the dual-gear design.

-

@donstauffer

..maybe replacing the needle roller bearing with a brass bearing would help?

They roll off under pressure like a 9-spoke wheel without rim.@all

we could try to put an acceleration sensor to the idler pressure lever and check the reading for countable peaks.

Is it 17 peaks or 9 peaks or just 1 peak per turn? ( 17 teeth, 9 needles or just a wobbling gear)