What would you build if you were starting again now?

-

@zapta said in What would you build if you were starting again now?:

I wish that Duet would have a reasonably price stand alone board with 7+ drivers and WiFi.

...like the Duet Maestro with 2-channel expansionboard?

-

@opentoideas said in What would you build if you were starting again now?:

With the knowledge you now have if you were building a new machine what geometry and machine type you build?

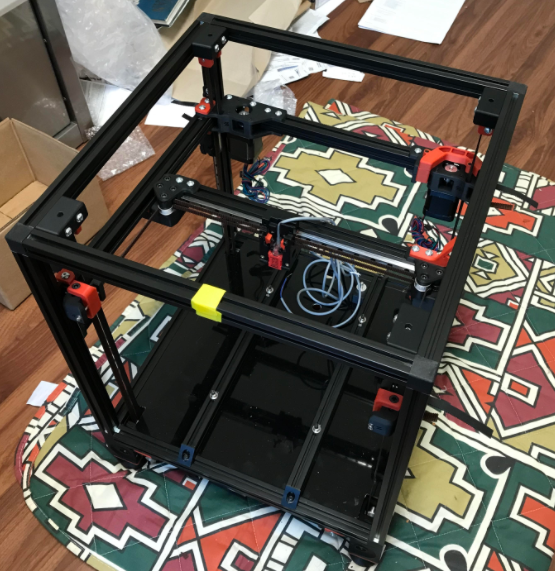

I am actually building a new machine, a black and red Voron V2.4 250mm with Clockworks (direct) extruder.

Sources the parts individually per the sourcing guide, which took a while, and the frame and x/y/z movements are already assembled.

I picked the Voron because it has a strong supporting community (I can get answers within seconds on Discord, or watch detailed videos by Nero 3DP) and it's a proven design with 1000+ people that built it. The design is on the overkill side, but I am taking my time and am happy with the results so far, especially with how stiff the x/y carriage is compared to my existing HEVO.

-

@o_lampe said in What would you build if you were starting again now?:

...like the Duet Maestro with 2-channel expansionboard?

I meant a single board, no expansions, for simplicity, and for avoiding CAN bus based issues.

As for the Maestro, IIRC it has no Wifi and limited MCU that is marginal for the upcoming input shaping.

The Chinese competition, with capable low cost non-clone new boards is becoming strong, and Duet's lead is shifting to better customer support and warranty rather than hardware feature set.

-

@zapta I think @o_lampe maybe meant Duet 3 Mini 5+ WiFi with Mini 2+ expansion board. Also pretty cost-effective (when you factor in documentation, support, community as well) against cheap Chinese boards.

While there is a market for standalone boards with 7+ drivers, it's not a big one. Most machines still only use 4 or 5 drivers. There's also more to go wrong on a larger, integrated PCB, and brick a whole board. There was also more demand for having tool boards rather than monolithic, single wiring point electronics, hence CAN is used now.

Ian

-

@zapta said in What would you build if you were starting again now?:

I meant a single board, no expansions, for simplicity, and for avoiding CAN bus based issues.

The Duet 3 Mini + 2-driver expansion doesn't use CAN, the expansion is a daughter board.

Whereas the Spider board with 7 drivers is a main board + 7 daughter boards. And it needs a Pi if you want a web interface.

So Duet wins on simplicity.

-

I'm not sure what I would rebuilt , but what I know is , Gentleman we can rebuilt it , we have the technology , we make it better , stronger , faster.

-

@droftarts said in What would you build if you were starting again now?:

Most machines still only use 4 or 5 drivers

A big plus for Deltas here, they only need 3 steppers for the whole motion system, where others use 3 steppers only for Z-axis.

-

Delta is tempting my main issue is spending the money on the materials to do it right in the first place which I know is the best way to go but I suspect I will probably end up trying to start with a working machine then upgrade it to (hopefully) make it close to what I want.

I was having a look around and if I got something like an Anycubic Predator it should at least work to start with and it seems to be at least a solid frame. I could then slowly spend the money I should have spent in the first place to make it better. the electronics are rubbish but then seeing as I am here its no surprise how to resolve that problem and then linear rails, rods and smart effector might make it the basis for a good machine in the end...

the biggest problem is the initial outlay. from the Blog DC42 posted while his machine I have no doubt is far superior I cant justify £1k initial outlay but a few hundred then a few hundred more LOL I might get away with sneaking that past the wife!

-

@o_lampe said in What would you build if you were starting again now?:

A big plus for Deltas here, they only need 3 steppers for the whole motion system, where others use 3 steppers only for Z-axis.

I can't buy that argument. People might choose to use multiple Z motors but that's a personal choice and a single motor driving multiple screws is a perfectly viable solution, even with a large heavy build plate. So whether it be Cartesian, or CoreXY then 3 motors are perfectly viable for X, Y and Z. My personal preference is CoreXY because for all moves other than 45 degree infill, then both motors contribute to motion. And for those 45 degree moves which use a single motor, there is an increase in available torque due to the gearing effect of the belt path.

-

@zapta May I reccomend you use the single MGN12 rail for X, unless you already have, using dual MGN9's were causing a torsion.

The 'clicky' probe as opposed to the inductive, or there is a MGN12 BLT mount for the AfterBurner.I was going to rebuild mine with a 1LC and mini5+ and the expansion board, but lost faith with the gantry.

As I mentioned above, the gantry is doing too much.X/Y/Z on rubber bands!

Hope yours works well.

-

@dc42 said in What would you build if you were starting again now?:

The Duet 3 Mini + 2-driver expansion doesn't use CAN, the expansion is a daughter board.

That's a good combination, thanks, I will look into it, and indeed direct interface between the MCU and all the 7 drivers. My original plan was to first build a stock Voron (Spider + SBC) and then mod it but may go directly with Duet.

Any reason why not using the Mini+2 for Voron 2.4?

-

@droftarts said in What would you build if you were starting again now?:

While there is a market for standalone boards with 7+ drivers, it's not a big one. Most machines still only use 4 or 5 drivers.

The Chinese vendor address it by using plugged in driver modules. This way you pay only for what you use. On the down side, it looks ghetto.

@PaulHew, I already assembled the X with two stock rails, but will look for mods once the base configuration will work.

-

@zapta I run this very combination together with a 1LC V1.1 toolboard, works extremely well.

-

@zapta a TMC2209 is about 1.5$ on digikey if you buy large enough quantities and can be SMD assembled while soldering the stepstick headers is fairly expensive - I doubt there are huge savings by keeping the drivers of the PCB.

-

@deckingman said in What would you build if you were starting again now?:

@o_lampe said in What would you build if you were starting again now?:

A big plus for Deltas here, they only need 3 steppers for the whole motion system, where others use 3 steppers only for Z-axis.

I can't buy that argument. People might choose to use multiple Z motors but that's a personal choice and a single motor driving multiple screws is a perfectly viable solution, even with a large heavy build plate. So whether it be Cartesian, or CoreXY then 3 motors are perfectly viable for X, Y and Z. My personal preference is CoreXY because for all moves other than 45 degree infill, then both motors contribute to motion. And for those 45 degree moves which use a single motor, there is an increase in available torque due to the gearing effect of the belt path.

Point taken; we don't have to use more than one Z-driver. But the real life tells a different story.

Some even use two X and Y motors, it must be an unknown virus

-

@o_lampe said in What would you build if you were starting again now?:

@deckingman said in What would you build if you were starting again now?:

@o_lampe said in What would you build if you were starting again now?:

A big plus for Deltas here, they only need 3 steppers for the whole motion system, where others use 3 steppers only for Z-axis.

I can't buy that argument. People might choose to use multiple Z motors but that's a personal choice and a single motor driving multiple screws is a perfectly viable solution, even with a large heavy build plate. So whether it be Cartesian, or CoreXY then 3 motors are perfectly viable for X, Y and Z. My personal preference is CoreXY because for all moves other than 45 degree infill, then both motors contribute to motion. And for those 45 degree moves which use a single motor, there is an increase in available torque due to the gearing effect of the belt path.

Point taken; we don't have to use more than one Z-driver. But the real life tells a different story.

Some even use two X and Y motors, it must be an unknown virus

It has been known for people to fit extruders on additional gantries on Delta printers, such that they follow the Z axis. So even Delta style printers are not immune from the "additional motor virus".

-

It is because there are several types of machines that need more than the usual number of motors that we decided to make the Duet 3 Mini capable of driving 7 motors before needing CAN expansion. We originally designed it for 8 motors using a 3-driver daughter board, but we ran out of microcontroller pins to control the 8th motor.

However, on a Voron or similar machine with direct drive extruder, using a CAN-connected tool board on the print head to connect the extruder motor, heater, thermistor, hot end fan, print cooling fan, Z probe, X endstop and accelerometer saves a lot of wires.

-

@dc42

With the restriction that the voron (2.4) uses an inductive sensor, and that is currently not yet supported.

This is exactly the point at which I gave a friend the recommendation for toolboard and mini and he now has to lay 3 additional wires. -

@diy-o-sphere said in What would you build if you were starting again now?:

With the restriction that the voron (2.4) uses an inductive sensor, and that is currently not yet supported.

I can think of no reason why you can't connect an inductive sensor to a tool board, in the same way that you would connect one to a Duet 3 main board.

-

so what are the inherent strengths and weaknesses of the current options?

Delta - tall for the build height reliable and proven looks like multi head printing is tricky though not impossible

CoreXY - strong structure but quite large footprint for the build area. long belts and multiple idlers "may" introduce errors as it wears

CroXY - looks the strongest again bigger footprint for the build area penalty for strength is the greater moving mass and complexity of multiple motors

these are the few things I have noticed but they are less important than reliability and print quality. speed is always welcome but subservient to print quality