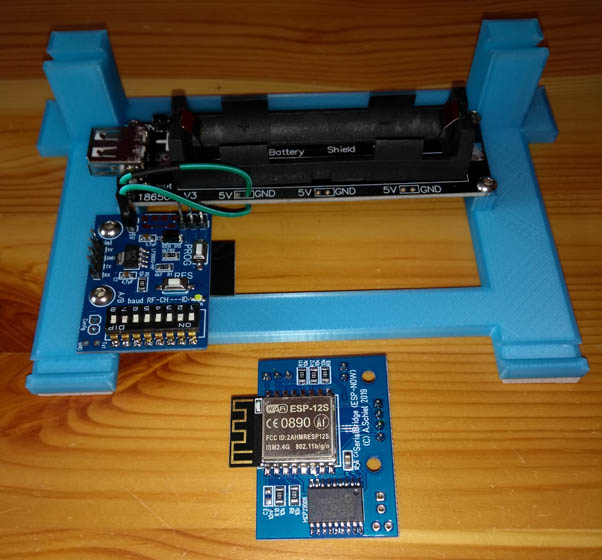

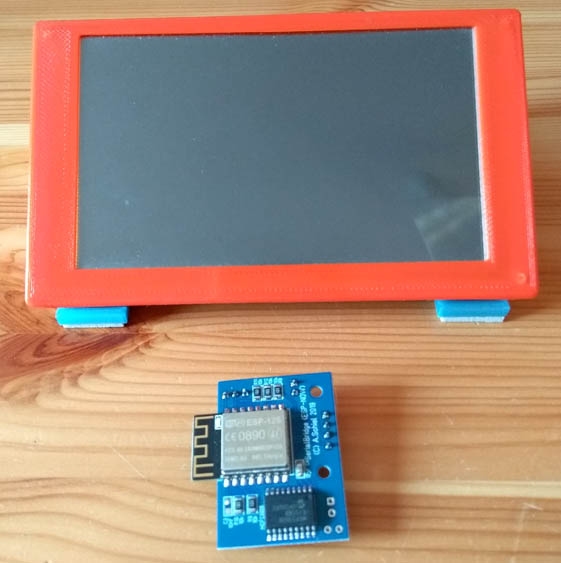

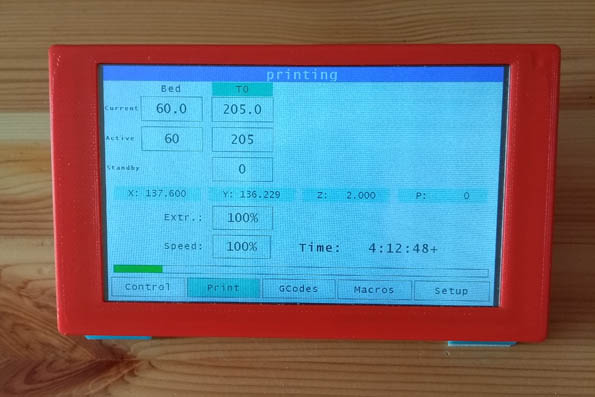

No, i dont have a PanelDue. I made a little monitor myself. You can see it here https://www.duet3d.com/forum/thread.php?id=222. Its based on a Teensy 3.2 and a 2.8" display with touch.

I adapted some code from the PanelDue source: json-parser (added code to receive no-json data lines), processing received values (only the structure) and sending commands with line-nr and checksum.

It sends M408 with checksum and gets a response. Commands to set temperature are received on the Duet and acted on.

Data in json-message and without json-format are displayed in a console-window.

Yesterday I programmed a window to type in commands on a virtual keyboard and send them. At that time I had a M575 P1 B57600 S1 in config.g and the commands were send with checksum. If I send M140 S50 the bed will heat and G28 will home my delta. So commands are recognised. But M119 will get no response.

For testing I set M575 P1 B57600 S0 in config.g and took out code to send line-nr and checksum.

Behavior stays the same.

I'm confused. Is the PanelDue sending some special characters? I searched in the source code but cound't find anything special.

Some testing:

I connected Duet via USB to my PC and opened a serial console for debugging.

I send with my little Duetmonitor M111 P3 S1 and debugging is on. The message is also received on the Duetmonitor.

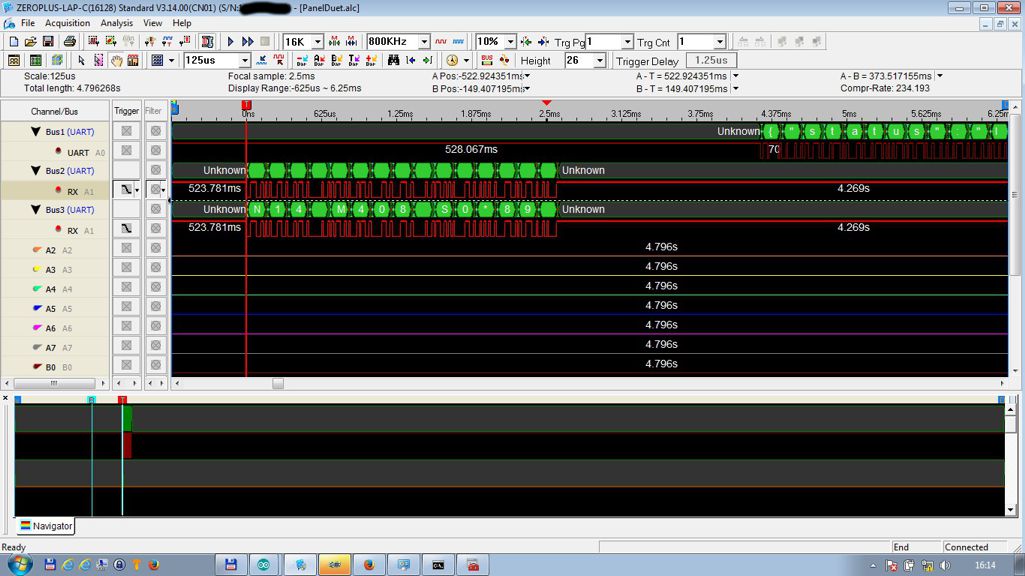

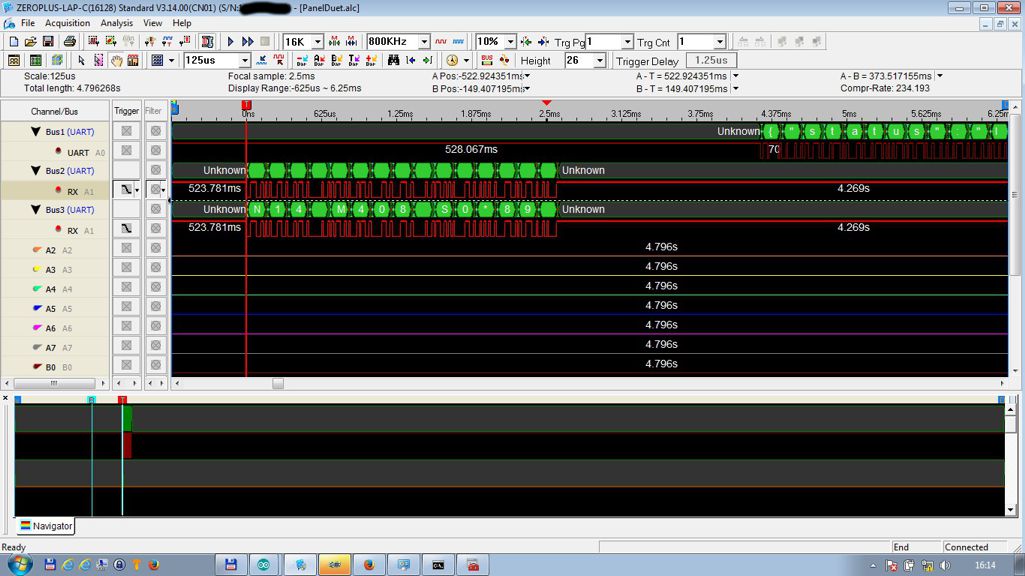

Then I send M408 S0. The command is recognised and I have attached a screenshot from the logic analyser.

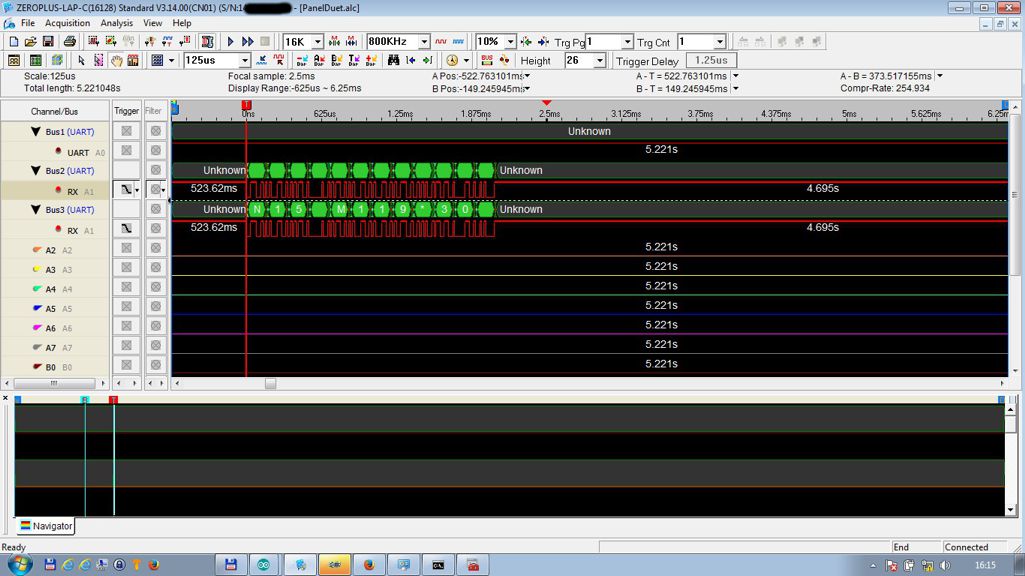

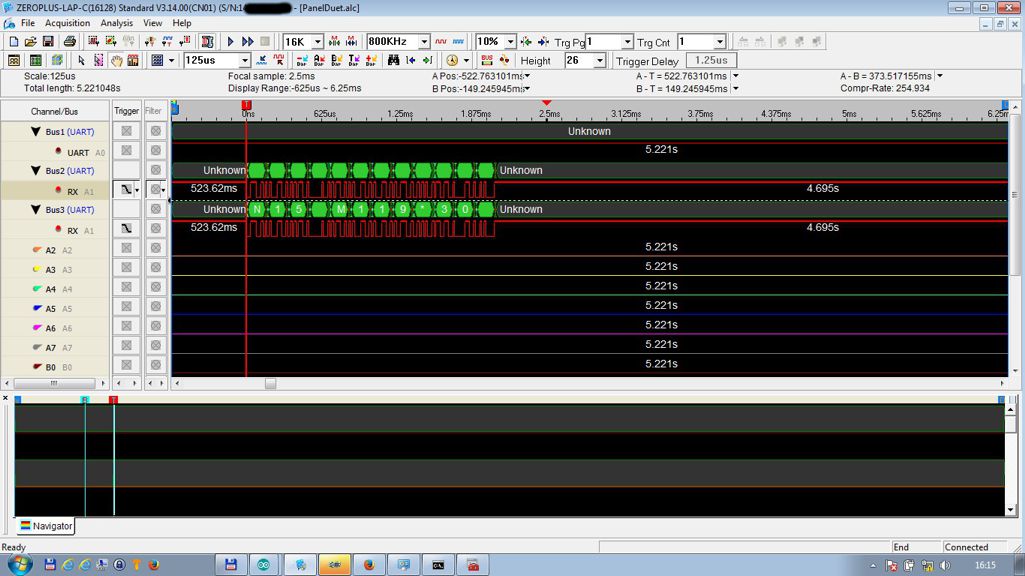

Direct afterwards I send M119, and attached another screenshot, where you can see, that there is no response. In USB debugging both command are recognised.

USB debugging:

Debugging enabled for modules: GCodes(3)

Debugging disabled for modules: Platform(0) Network(1) Webserver(2) Move(4) Heat(5) DDA(6) Roland(7) PrintMonitor(8) Storage(9)

aux: N14 M408 S0*89

aux: N15 M119*30

Class GCodes spinning.

Send M408 S0:

Send M119:

I attach my config.g so you can have a look if there is something interfering.

; Configuration file for Mini Kossel kit from Think3DPrint3D for Duet WiFi

; Communication and general

M111 S0 ; Debug off

M550 PMiniKosselWiFi ; Machine name and Netbios name (can be anything you like)

M551 Preprap ; Machine password (used for FTP)

;*** If you have more than one Duet on your network, they must all have different MAC addresses, so change the last digits

M540 P0xBE:0xEF:0xDE:0xAD:0xFE:0xED ; MAC Address

;*** Wifi Networking

M552 S1 ; Enable WiFi

M555 P2 ; Set output to look like Marlin

M575 P1 B57600 S0 ; Comms parameters for PanelDue

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

; Axis and motor configuration

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes backwards (geared Extruder)

M569 P4 S1 ; Drive 4 goes forwards

M574 X2 Y2 Z2 S1 ; set endstop configuration (all endstops at high end, active high)

;M574 E1 S1

;*** The homed height is deliberately set too high in the following - you will adjust it during calibration

M665 R101.56 L215.0 B85 H227.31 ; set delta radius, diagonal rod length, printable radius and homed height

M666 X0.05 Y0.14 Z-0.19 ; put your endstop adjustments here, or let auto calibration find them

M350 X16 Y16 E16 I1 ; Set 16x microstepping with interpolation

M92 X80 Y80 Z80 ; Set axis steps/mm

M906 X1000 Y1000 Z1000 E800 I60 ; Set motor currents (mA) and increase idle current to 60%

M201 X1000 Y1000 Z1000 E1000 ; Accelerations (mm/s^2)

M203 X20000 Y20000 Z20000 E7200 ; Maximum speeds (mm/min)

M566 X800 Y800 Z800 E1200 ; Maximum instant speed changes mm/minute

; Thermistors

M305 P0 T100000 B3950 R4700 H0 L0 ; Put your own H and/or L values here to set the bed thermistor ADC correction /H36

M305 P1 T100000 B4388 R4700 H0 L0 ; Put your own H and/or L values here to set the first nozzle thermistor ADC correction /H20

M305 P2 T100000 B4388 R4700 H0 L0 ; Put your own H and/or L values here to set the second nozzle thermistor ADC correction

;M570 S180 ; Hot end may be a little slow to heat up so allow it 180 seconds

; Fans

M106 I0 ; fans are not inverting

M106 S0 ; Turn off Fan 0

M106 P1 F100

M106 P1 H-1 ; disable thermostatic mode for fan 1

M106 P1 S0

M106 P2 I1 H-1 F87 ; disable thermostatic mode for LEDs, set PWM frequency, output inverted

M106 P2 S0.15 ; LEDs on at 15%

; Tool definitions

M563 P0 D0 H1 ; Define tool 0

G10 P0 S0 R0 ; Set tool 0 operating and standby temperatures

;*** If you have a single-nozzle build, comment the next 2 lines

;M563 P1 H2 ; Define tool 1

;G10 P1 S0 R0 ; Set tool 1 operating and standby temperatures

M92 E695 ; Set extruder steps per mm (100 / gemessener Vorschub * aktuelle Steps)

; Z probe and compensation definition

;*** If you have a switch instead of an IR probe, change P1 to P4 in the following M558 command

M558 P5 X0 Y0 Z0 ; Z probe is hall sensor and is not used for homing any axes

G31 X0 Y0 Z-0.15 P500 ; Set the zprobe height and threshold (put your own values here)

;*** If you are using axis compensation, put the figures in the following command

M556 S78 X0 Y0 Z0 ; Axis compensation here

M208 S1 Z0.0 ; set minimum Z

M207 S3.5 F4500 Z0.1 ; set hardware-retraction

M572 D0 S0.15 ; set extruder advance

M307 H0 A87.3 C285.3 D8.3 B0 ; set bed heater model

;

T0 ; select first hot end