@SDJ

If that is true, it's really good news. It sure seemed like it had become abandonware.

I definitely prefer Superslicer to anything else I've tried.

Each slicer has some things that are cool, and others that are kind of annoying or lacking, but SS was definitely the sweetspot, at least for me.

Posts made by omni

-

RE: Orca slicer and Duetposted in General Discussion

-

RE: TPU Shore 60Aposted in 3D Printing General Chat

@omni Yea, another great thing about this method is that my gasket was actually quite complex - it had multiple points of contact on the lower side, so it was not a simple O-ring (more like a 3D o-ring) and I could not find a replacement anywhere. So you can make even complex gaskets.

I tried TPU printing, but anything below 70A is actually quite tricky to pull off nicely. especially if it's a bit complex, and there is always the seam issue with FDM, layers, tolerances, etc. For gaskets - printing a resin mold and using a purpose gasket compound is the way to go.... it also tolerates temperatures up to 200c, does not deform from water exposure and high pressure, etc.

-

RE: TPU Shore 60Aposted in 3D Printing General Chat

The idea was to put more material than needed (tighly packed into the mold straight from the tube) and then just compress it and let the extra material and and some air flow out of the holes.... It turned out great actually, just needed a bit of sanding where I cut the excess, but it's a 3 minute work.

For the mold release I used a puropse mold release wax (usually used for resin pouring) but since this RTV is silicone based, you can probably get away with a few drops of fairy dishwashing detergent spread all over, since silicone does not stick to it at all....

And one important thing, my mold was printed on a resin printer, so the tolerances were very tight and precise and the surface finish was excellent.

-

RE: TPU Shore 60Aposted in 3D Printing General Chat

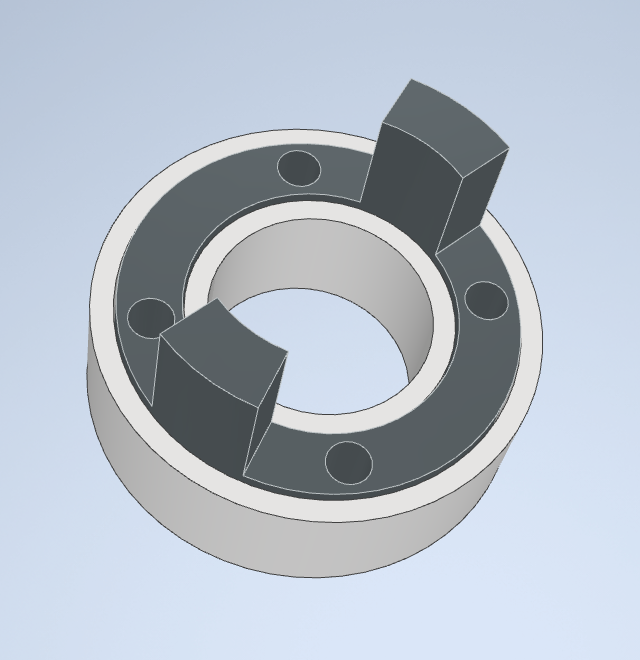

Can't find the original file for the gasket mold, but I skecthed something fast along those lines.....

Fill the light gray part with rtv, push the dark gray part inside, the excess goes out from the holes.... when it cures, you just cut it out with a scalpel.

But you need to do it fast while it's still viscous, since it cures quite quickly.... Also my gasket was rather large, so I guess it would be a bit difficult to squeeze it out if the holes were very small....

-

RE: TPU Shore 60Aposted in 3D Printing General Chat

@jens55 Well, with the rtv I just kind of overpoured it into the mold and made a mold in such a way that it squeezes out the excess... Then when it cured I just did a little bit of postprocessing with a scalpel / rotary tool. Don't know if there were any significant air pockets but it sure worked well enough, and going strong for more than a year now. The second one is pretty much liquid, you can pour it easily. I still haven't used it but it was recommended to me by a person who uses it regularly so I bought it as a backup option. Didn't yet need it since this rtv worked great.

-

RE: TPU Shore 60Aposted in 3D Printing General Chat

If you can, get one of these products:

Just print a mold, use some mold release, and you will make a perfect gasket.

I did not read the entire thread, but also make sure the 3d printed part itself is waterproof. Print it solid or dip it in resin after printing to make sure it's 100% waterproof. I made some critical parts and gaskets for a waterpump and it took me some trial and error before I made it 100% reliable.

-

RE: Orca slicer and Duetposted in General Discussion

@button Thanks, good to know. I was hesitant to try it out since it looks mainly Klipper oriented, but I'm gonna go ahead and set it up...

-

RE: BIQU Microprobeposted in Third-party add-ons

@jens55 Well yes, you might be right if it's a small by surface but very thick bed and well insulated it might not make such a big difference. I have a 525x525x6mm bed and it warps like crazy when heating / cooling. It can be +/- 0.5mm difference in corners. That is why I adjust and probe the bed only when fully stable at the printing temperature. But I don't think there is a need to turn off the bed while probing if you are using bltouch. For some other types of probes maybe...

-

RE: BIQU Microprobeposted in Third-party add-ons

@jens55 Well that may well be your main problem - you are probing a cold bed or a hot bed which is cooling during the probing since your bed heater is off. The aluminium plate can warp and fluctuate in height BY A LOT in just a matter of seconds depending on the isolation, much more than the problem of accuracy of the probe. Before you probe the bed you need to make it stabilize in tempreture and keep the printing temperature of the bed (preferably with PWM) at all times during the probing in order to get the most accurate results. Probing it cold or during cooling is pretty much useless if you are looking for very high accuracy during printing. 0.003 repeatability is plenty, those are not values that you are going to notice. But bed height fluctuating +/- 0.3mm because of the cooling you are definitely going to notice...

-

RE: BIQU Microprobeposted in Third-party add-ons

@jay_s_uk I've just ordered one.... looking forward to testing it.

-

RE: BIQU Microprobeposted in Third-party add-ons

@jens55 The first versions of BLtouch had problems.... but V3.1 has been working almost flawless-ly for me for years. Check what version you have and also it might be susceptible to inteference, so if you are running unshielded stepper wires in parallel to Bltouch wires, maybe that can cause accuracy problems. I have it installed exactly the same as in the Duet Docs, with 5 wires (veeeery long by the way), but all my stepper cables are shielded and it has been performing like a champ. The only issues I had were chamber temperature related.... since it can have missreadings if the chamber temperature is too high....

-

RE: BIQU Microprobeposted in Third-party add-ons

@jay_s_uk

Thanks for the reply.

I mostly print on glass, but I've tried pretty much all types of probes in the past (inductive, ir, piezo, microswitch, etc.) except the new scanning type (like the Beacon) and I've always returned to Bltouch because it has been the most reliable/convenient choice - so if there is an improved version of that approach - I would love to try it out. The only situations in which I had repeatability issues with bltouch is when I heat the chamber above 45-50 degrees - but that is rare and even that was solvable with repeated probing until two consecutive ones are withing a very small range. -

BIQU Microprobeposted in Third-party add-ons

Hi guys,

I was wondering if anyone has tried the BIQU Micropobe with DUET / RRF ?

If so, how do you think it compares to BLtouch V3.1?

It's interesting to me since from the very few reviews I could find it seems pretty accurate/repeateble, small and lightweight as well as a bit faster than bltouch since it does not retract after each probing and activates the moment it touches the surface. Also it seems to be using a switch rather than hall sensor, but I'm not sure about that one.

-

Orca slicer and Duetposted in General Discussion

Hi guys,

Is anyone using Orca Slicer with Duet and what are your experiences? In the initial configuration for a custom printer there is not even an option for a custom RepRap firmware printer (only Klipper and Marlin), but digging deeper in options there is a RepRap gcode flavor. Currently I am using SuperSlicer and like it, but Orca seems interesting, so before giving it a go I wanted to check out what you guys think?

-

RE: Switching from bang-bang to pid for a dual zone 1500w AC heaterposted in Tuning and tweaking

Ah thanks,... my bad, I was looking in the wrong place. I thought it was in the M307.

So initially it should look like this, if I am not mistaken :

; BED - ZONE 01 HEATER (CENTER) M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 Q11 ; create bed heater output on bedheat and map it to sensor 0 with PWM frequency of 11Hz M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater 1 and set PWM limit M140 H0 P0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M570 H0 S200 ; Set maximum heating time (Snnn, in seconds). ; BED - ZONE 02 HEATER (EDGE) M308 S2 P"e1temp" Y"thermistor" T100000 B3950 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 Q11 ; create bed heater output on bedheat and map it to sensor 2 with PWM frequency of 11Hz M307 H2 B0 S1.00 ; disable bang-bang mode for the bed heater 2 and set PWM limit M140 H2 P1 ; map heated bed to heater 1 M143 H2 S120 ; set temperature limit for heater 0 to 120C M570 H2 S200 ; Set maximum heating time (Snnn, in seconds).Then when I do the calibration, I should add the calibration parametars to M307?

Thanks again.

-

RE: Switching from bang-bang to pid for a dual zone 1500w AC heaterposted in Tuning and tweaking

@dc42 Thank you so much for the explanation, it makes sense.

Can you please suggest the inital config.g g-code for M307, and after I tune them both as you suggested, I will add the calibration parameters.

I can't seem to find the PWM frequency parameter in the docs, was it Q? And since I am not using VIN as power supply, but only for PWM should I exclude the V parameter from the M307?

-

Switching from bang-bang to pid for a dual zone 1500w AC heaterposted in Tuning and tweaking

Hi guys,

I have a large custom 520x520mm 1500w 230V AC - dual zone silicon heater for my printbed that I run through two independent ZG3NC-325B zero crossing SSR's.

The inner zone for smaller prints is 200x200mm - (300W) connected to "bedtemp" pin

The outer zone is the rest of the heater (1200W) - connected to "e1temp" pinSo far, I have been running it in bang bang mode, but since it is suboptimal for stable temperatures, I would like to try to switch to PWM to be able to PID autotune it properly.

ZG3NC-325B is a zero crossing SSR rated at 25A and from it's datasheet I can see it's on/off time is ≤10ms, so I think it can hadle PWM up to 100Hz, but I figure 10Hz is plenty for much more stable temperatures.

This is my current gcode (with bang bang) :

**; BED - ZONE 01 HEATER (CENTER) M308 S0 P"bedtemp" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 A97.3 C230.7 D2.8 S1.00 V24.2 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 P0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M570 H0 S200 ; Set maximum heating time (Snnn, in seconds). ; BED - ZONE 02 HEATER (EDGE) M308 S2 P"e1temp" Y"thermistor" T100000 B3950 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create bed heater output on bedheat and map it to sensor 0 M307 H2 B1 S1.00 A166.8 C910.6 D2.8 V24.2 ; enable bang-bang mode for the bed heater and set PWM limit M140 H2 P1 ; map heated bed to heater 1 M143 H2 S120 ; set temperature limit for heater 0 to 120C M570 H2 S200 ; Set maximum heating time (Snnn, in seconds).**Can you please suggest the correct procedure and initial GCODE for 10Hz PWM, so I can run the PID tuning for both zones at the same time (since that is what I usually mostly use).

I guess I should first just turn bang bang off, remove the current calibration parameters and set the PWM frequency, but since I haven't done this before - can you please help on the proper procedure and gcode.

I have the DUET 2 ETHERNET and run the latest RRF 3.5 BETA 3.

Thanks a lot in advance.

-

RE: Resume button cancels print instead of resuming 3.5.0-rc5posted in PanelDue

Flashed RC6, tested - seems to have been solved. Thank You!

-

RE: Resume button cancels print instead of resuming 3.5.0-rc5posted in PanelDue

@arhi I can try the M117 to debug, but it wasn't a human error, especially not twice. First time I wasn't sure, but since an important print broke I made sure 100% I pressed resume - and it said "print canceled"

What I do think noticed though is a kind of a short glitch - in the interface as if resume and cancel buttons were completely overlapped (like they are in the same place), but only resume can be seen. I am not 100% sure about that, but I don't even remember seeing cancel, only resume.