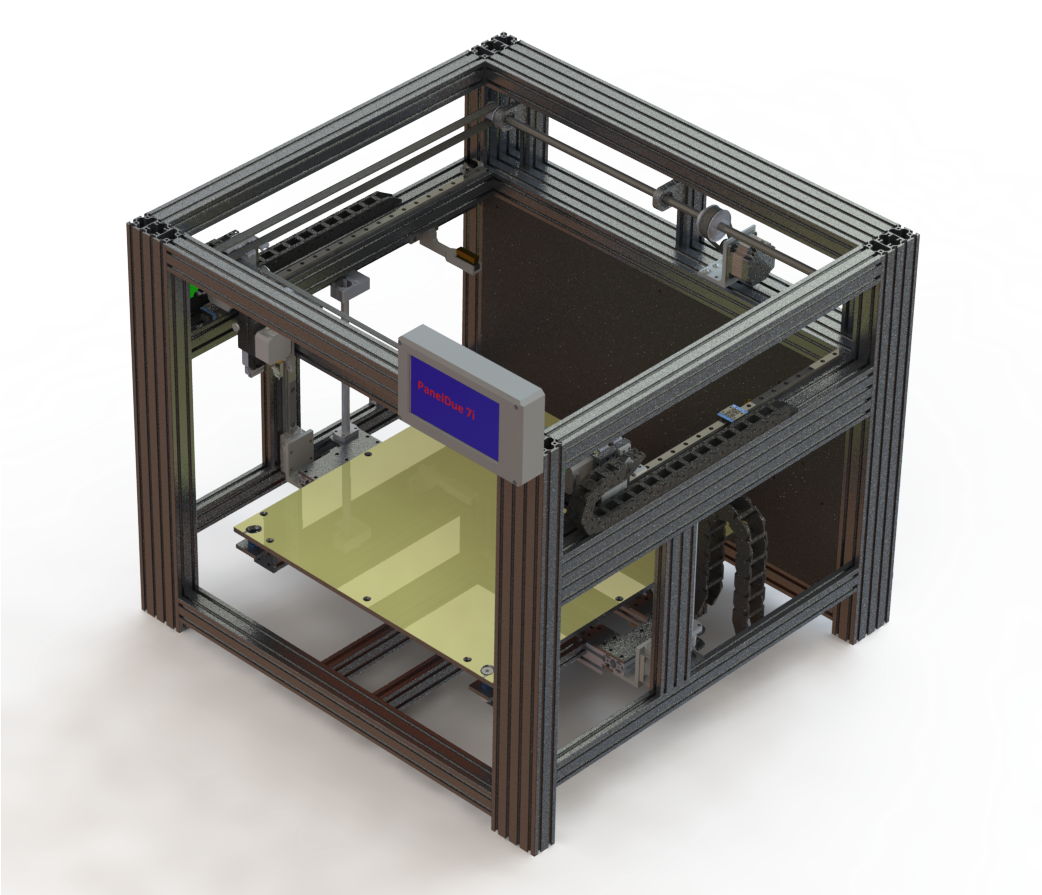

I'm pleased to share a personal project of mine, where the initial design started in late 2018, and purchasing started in March of 2019. By no means is this complete, but I'm at a point where I'm excited to share the progress I have made so far.

Some background - My first real experience with 3D printing was in 2017 at the office; we had a Stratasys Dimension 1200es BST that wasn’t getting much use. I started printing practically anything I could think of, starting with a small hand tool, and progressing to much larger and more sophisticated designs. In early 2018 I got the go-ahead to propose search for a new 3D printer model that we would buy two of – because more is better, right? At that point I realized both the age of the Stratasys machine, as well as the wealth of hardware and software options for printers available at the time.

We opted to go with two BCN3D Sigmax printers – dual extrusion was a must, the IDEX technology had some potential uses, and the large bed width was attractive. I spent quite a bit of time learning how to effectively operate those machines (they are surprisingly a lot of work!); later I picked up a used Davinci 1.0 and flashed it with Repetier, built a MPCNC, and eventually the Stratasys went belly-up and made its way home with me.

My initial design objectives were to have a machine that…

- Has a rigid frame

- Has a limited number of 3D printed components

- Has an enclosed and heated chamber

- Has a large print area

- Is capable of printing high temperature thermoplastics

- Is capable of dual extrusion

- Is capable of fast travel speeds with reasonable accelerations

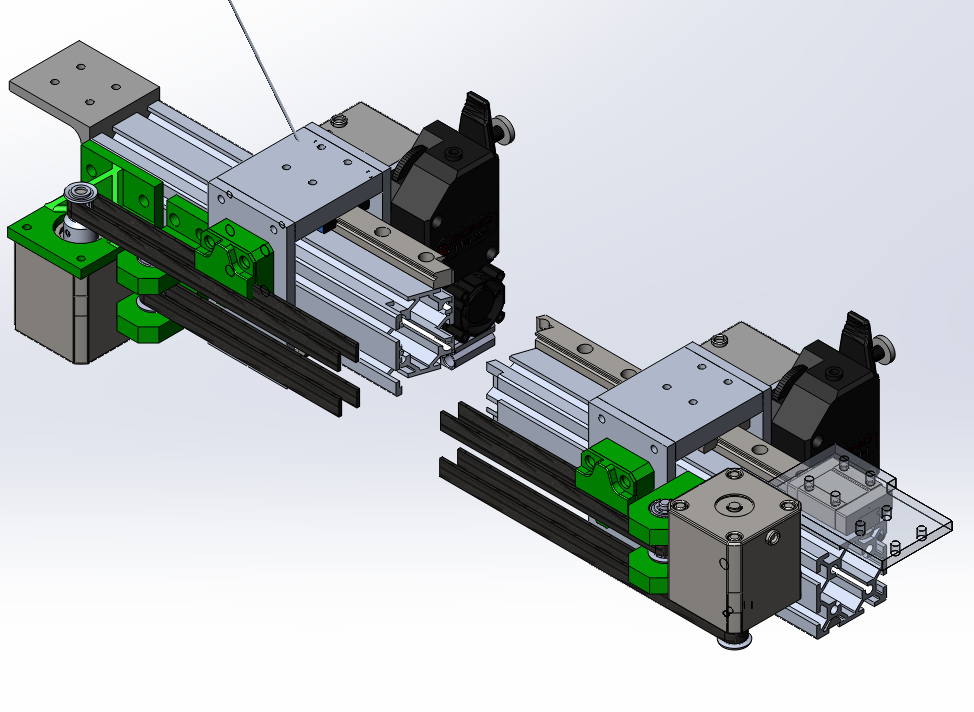

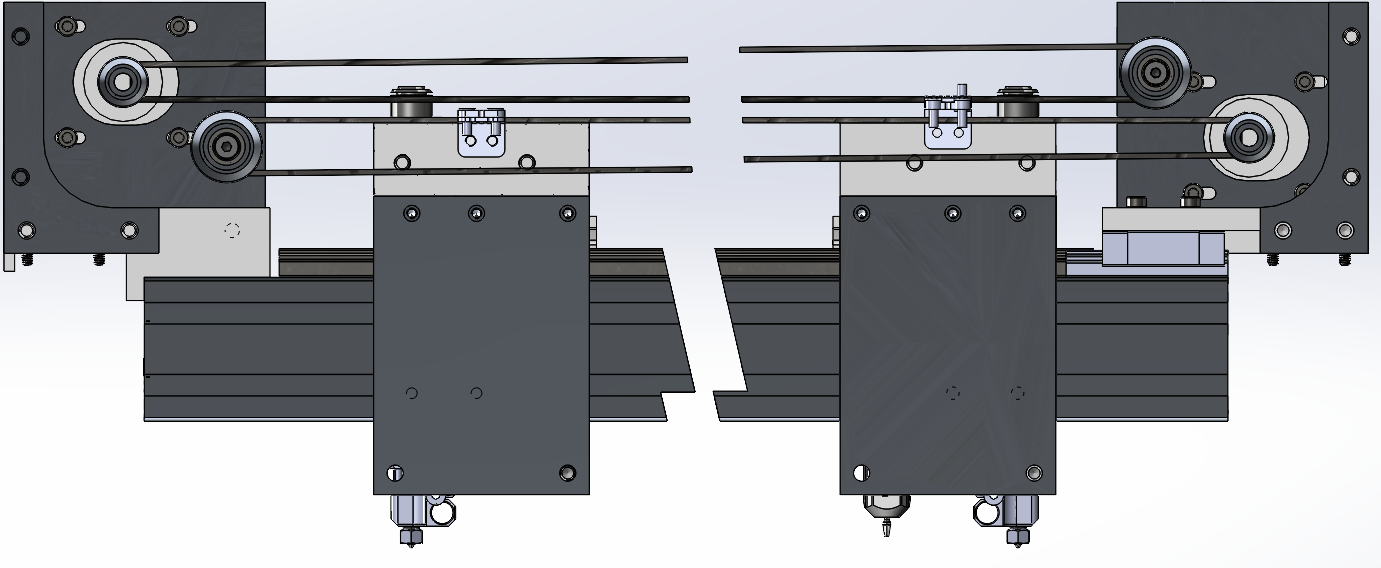

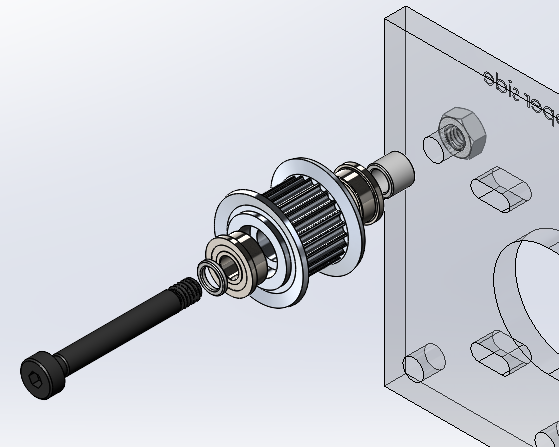

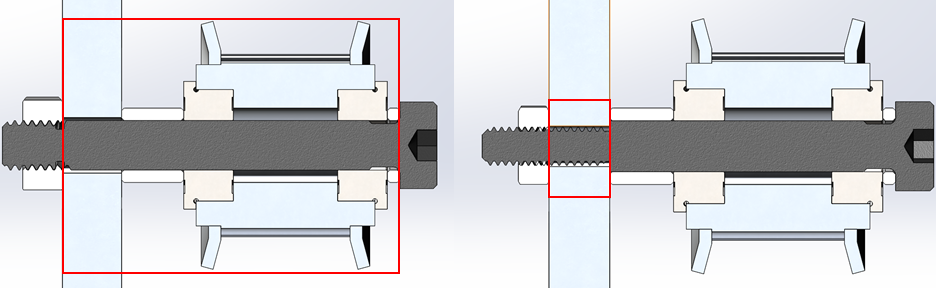

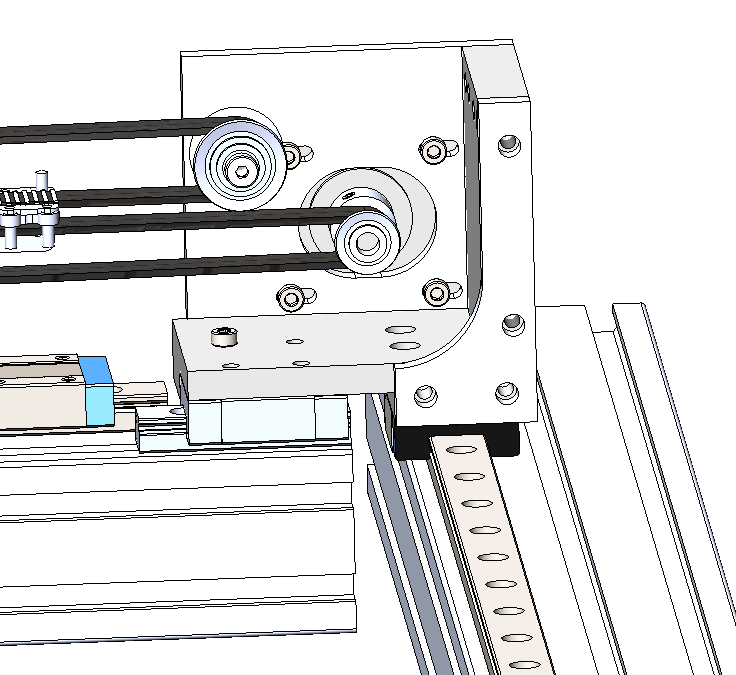

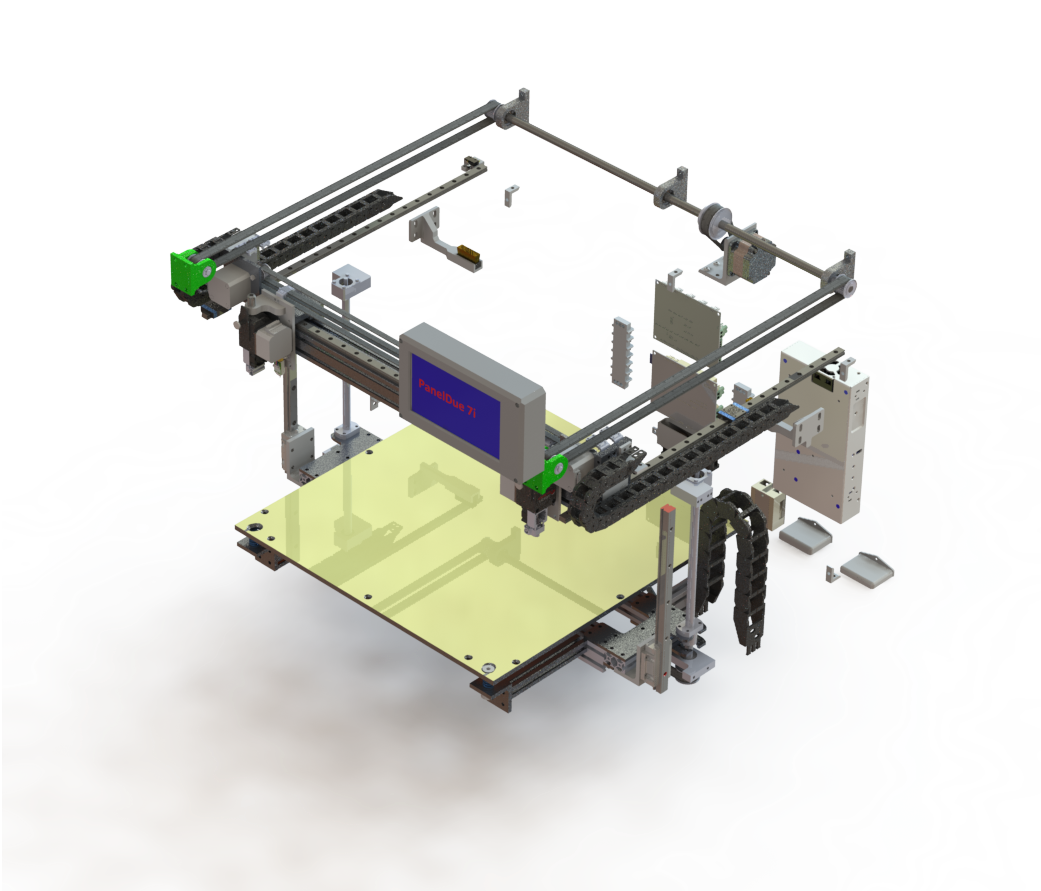

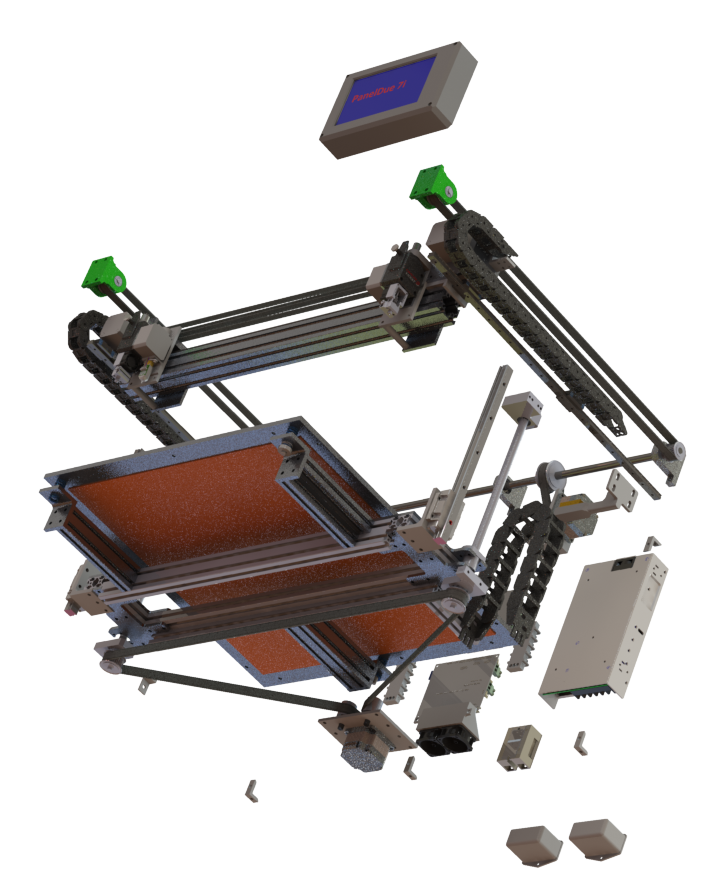

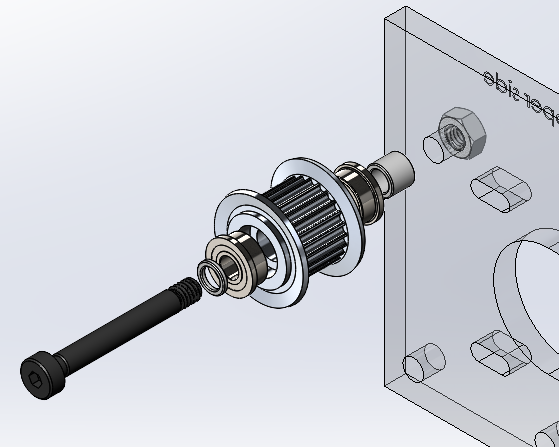

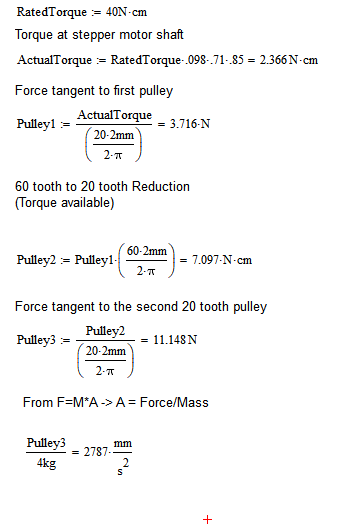

To start the design, I purchased two Rexroth ballscrews and 3x sets of IKO LWL12B 500mm rails with two ML12 each, sizing the frame to these components. Later on I purchased two LWHT15 200mm rails with a single carriage each for use with the ballscrews for the Z-Axis.

Other design and component decisions:

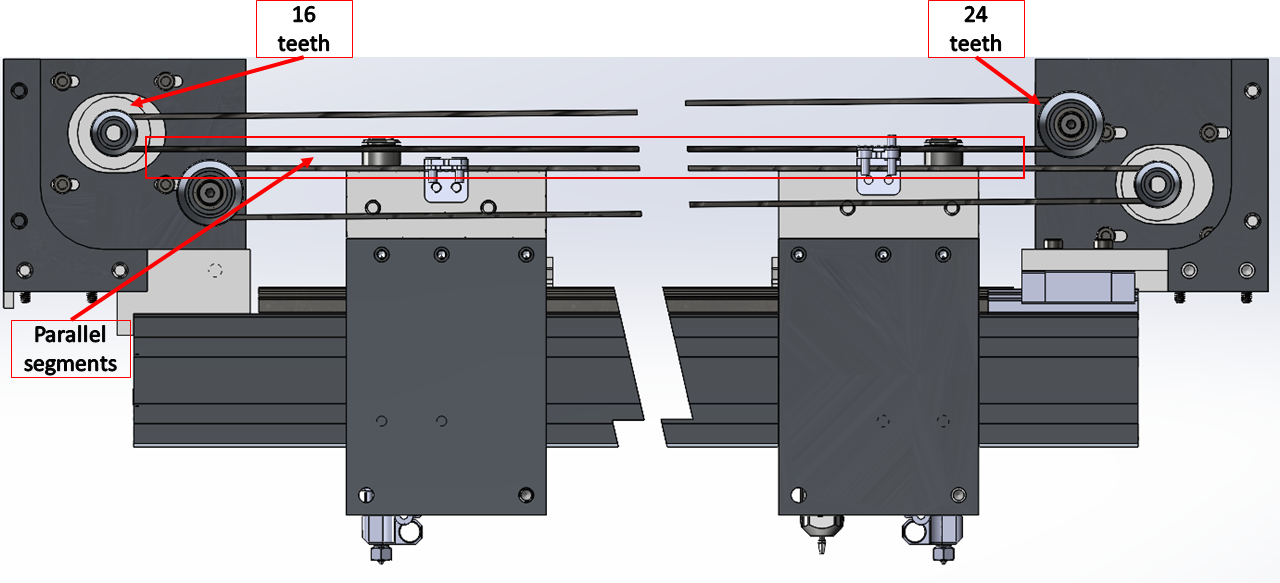

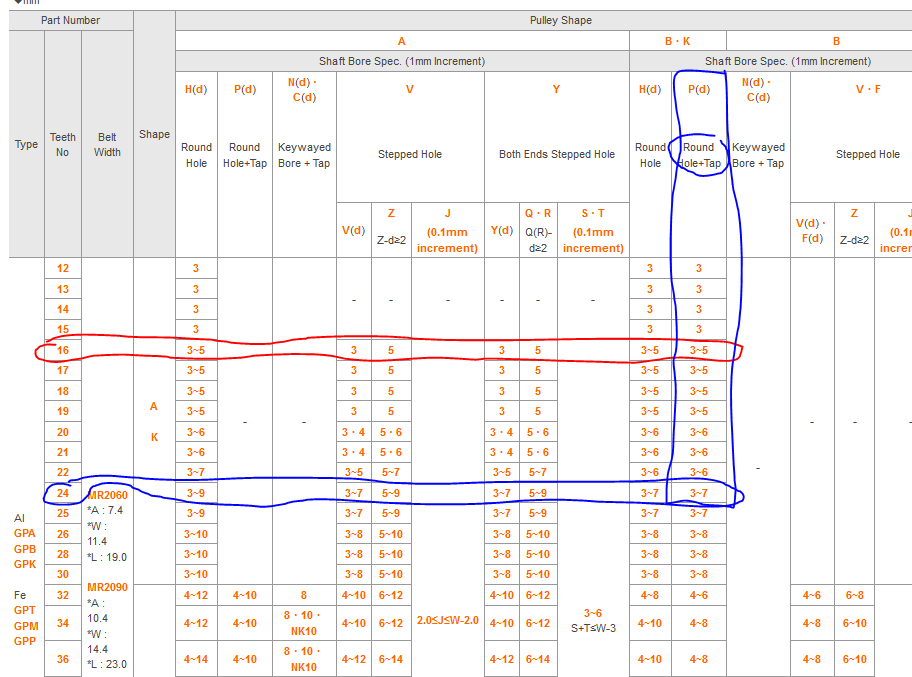

I wanted to utilize the Gates GT3 series of belts and compatible pulleys

- For the Y-axis I selected 3mm belt pitch, 15mm belt width

- For the X/U-axis, I selected 2mm belt pitch, 9mm belt width

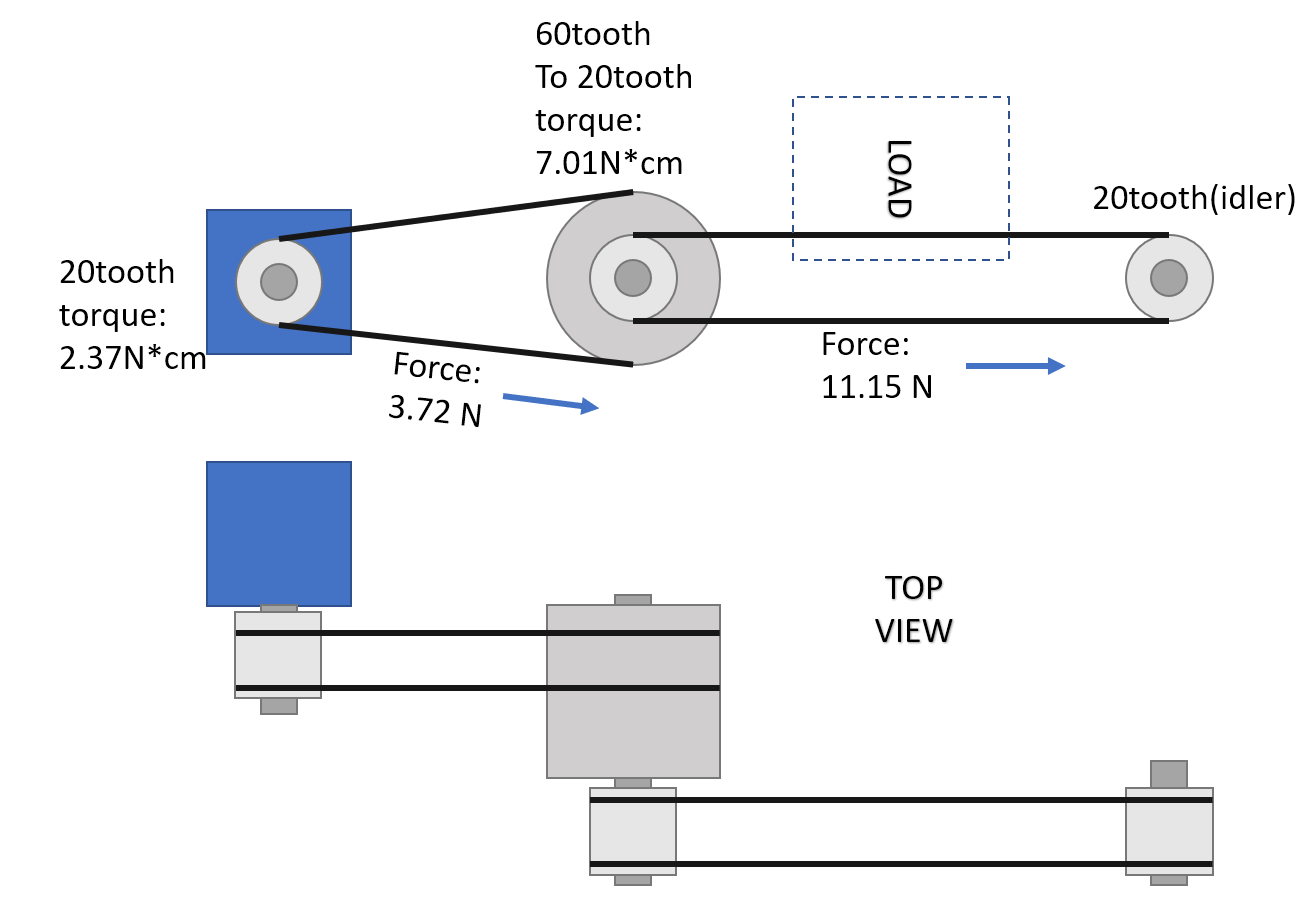

I wanted to balance speed and resolution

- 16x microstepping, managing to achieve 100steps/mm in the X/U axis, 96steps/mm in the Y axis

- Y axis is geared down with a 2.25:1 gear ratio to compensate for the heavier axis

- X, U, and Y axis run at 300mm/s max speeds and 4000mm/s^2 acceleration

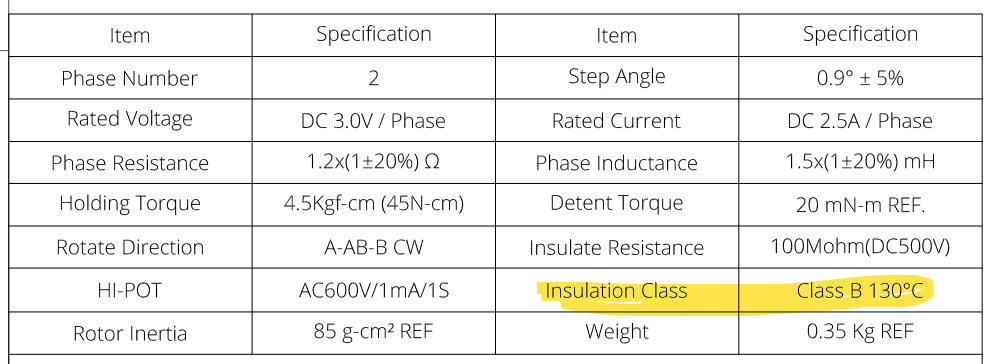

For the Y-axis and Z-axis, stepper motors are NEMA 23

- Oriental Motor PKP264D28AA2, .74 N*m, 2.8 A/phase, 1.5mH/phase

- Set to 2.4A in config.g

- Run super cool, barely feel warm to the touch

X and U axis use NEMA 17

- Oriental Motor PKP244D23A2, .48N*m, 2.3 A/phase, 1.9mH/phase

- Set to 1.8A in config.g

- These run quite a bit warmer than the NEMA 23s

Slice Engineering Mosquito and Mosquito Magnum for hotends

- Various nozzles (P3D, E3D NozzleX, Slice Vanadium

- Slice thermistors and heaters

- 12V Sunon fans

5/16” ATP 5 plate, 1000W Keenovo heater, SDF DF240S thermal cutoff (200°C holding temperature)

- TCO holding temperature may be a little high, but Keenovo recommended a maximum operating temperature of 204°C based on the 3M adhesive rating.

- Three-point bed leveling with probing

- Initially looked at a kinematic bed solution but opted for a fixed countersunk screw/spring combo, with two slotted countersinks sized and positioned to account for thermal expansion.

Bondtech BMG-M extruders

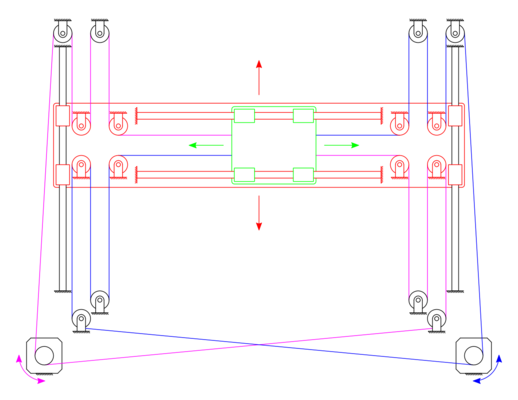

IDEX

- I do enjoy the IDEX technology on the BCN3D printers but wanted something a bit more structurally sound. Mechanically, lots of inspiration taken from the Stratasys Dimension 1200es.

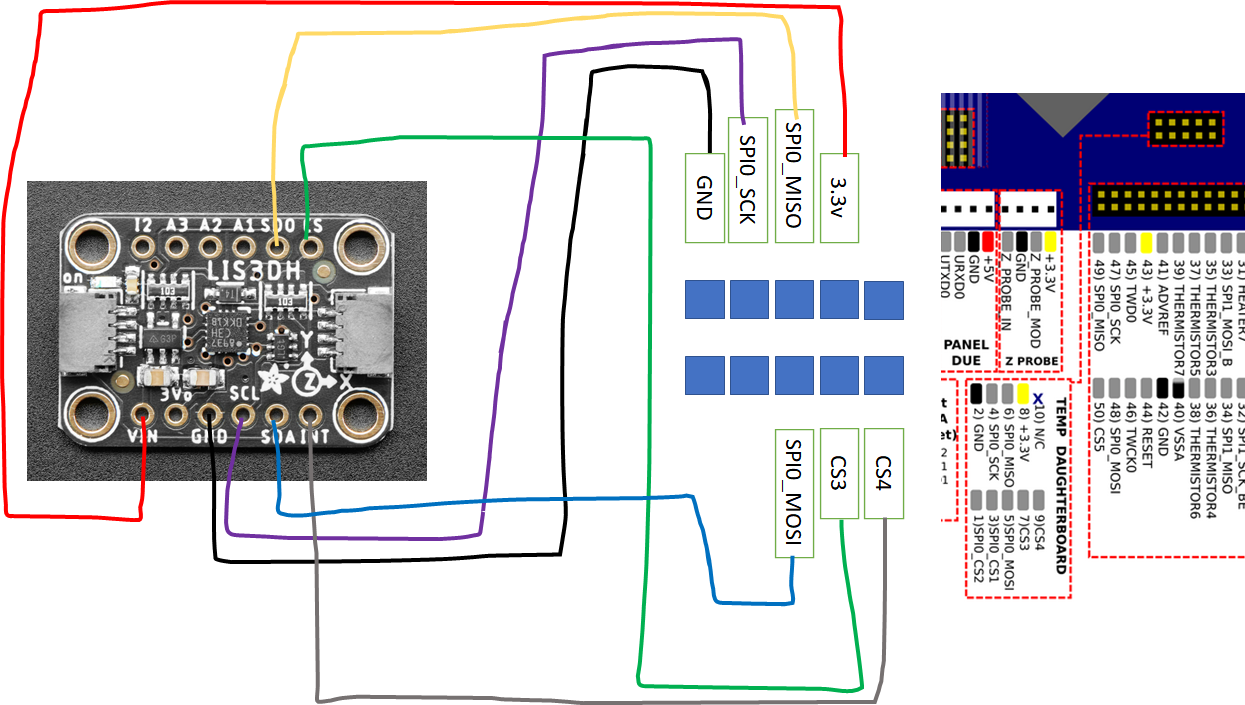

Duet controller board(s) - Duet 2 Wifi, Duex5, PanelDue 7i

Snap action homing switches for X, U, and Y

- These have moved quite a bit as the design has evolved, I’m not happy with how they are mounted at the moment

- Had a homing “oopsie” where the U assembly crashed into the X carriage, actually moving the switch mounting block, and messing up my calibration!

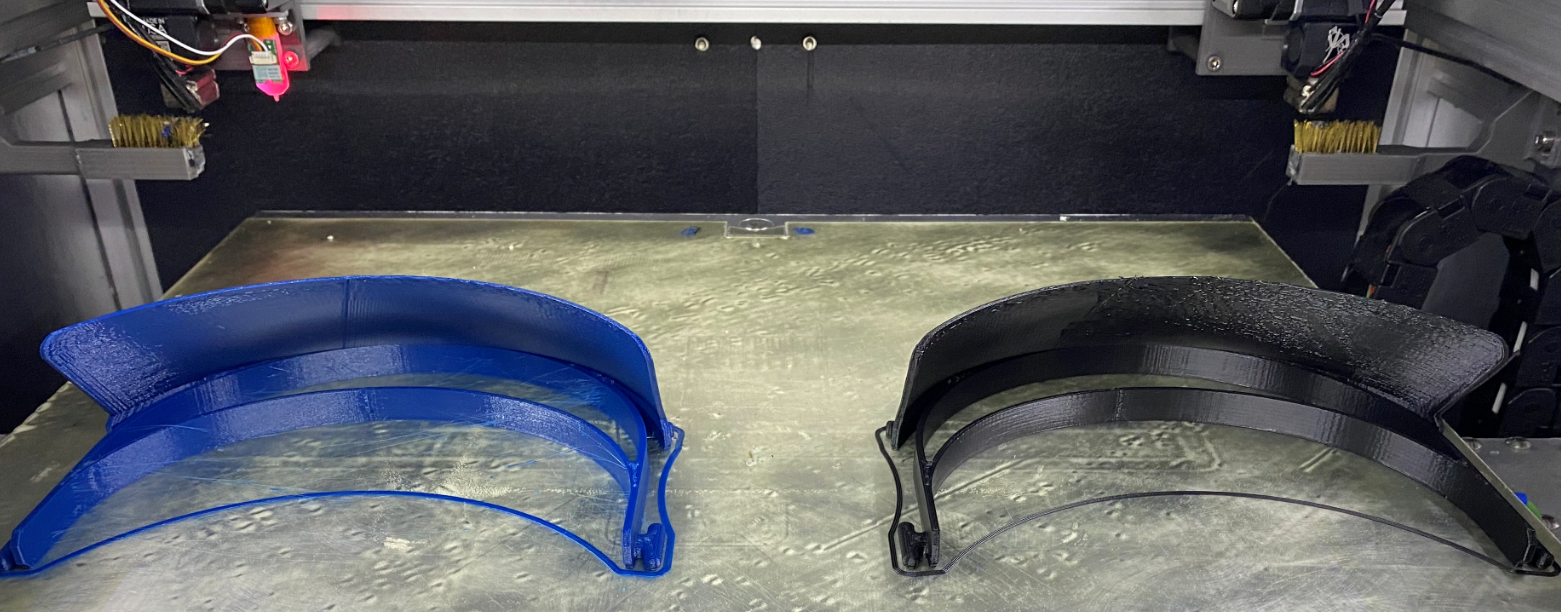

Right now I’m looking at a print volume (single extruder) of 420mm x 450mm (475mm Y travel) x 210mm, losing ~100mm (to ~320mm) on the X and U axis for dual extrusion (lesson learned there!).

The project so far has been a blast, with many lessons learned along the way. The X-U axis has by far been the most challenging to build and design, I’m on the second major iteration and I’m still not entirely pleased, although I am getting satisfactory print results. As this is my first printer design and build, it was challenging to prioritize assembly design priorities. With this project, despite having a good idea of the components I wanted on each hotend assembly, it was the last item I designed and built up – ends up my build plate was a bit too big, leaving me little room to have nozzle wipe stations, purge buckets, etc. On future projects I for sure have a better idea of what assemblies to prioritize, making further decisions based on the size and function of said assemblies.

While working on this project, I did not initially intend to share the design files, however because of all that I learned from the fantastic content and individuals on this community and others, I figured I should give back and contribute this project.

https://drive.google.com/drive/folders/12TOxGG-kKjuYwNuwhYpwor9TGhdfy2mg?usp=sharing

The Google Drive link contains a Solidworks (19-20) pack-and-go, as well as assembly parasolids (.x_t) and IGS files. A (very!) rough BOM and various images and videos of my progress are also available.

How have I done so far?

- Has a rigid frame - definitely nailed this one! Almost entirely end tapped extrusions with fasteners + access hole

- Has a limited number of 3D printed components - making progress, but not quite done. Y axis bearing holders, most of the hotend carriage assembly is still 3D printed

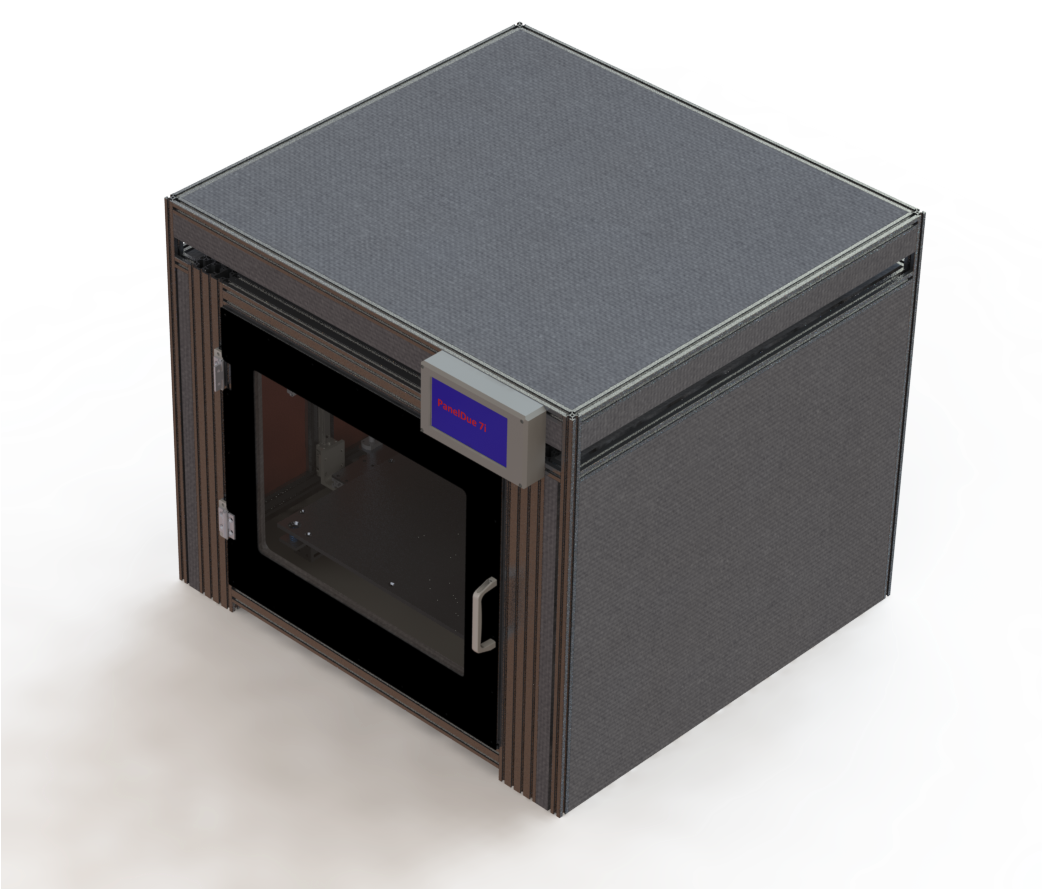

- Has an enclosed and heated chamber - making progress on enclosure, have not installed+tested active chamber heating (excluding built plate)

- Has a large print area - pretty satisfied

- Is capable of printing high temperature thermoplastics - goes hand in hand with the heated enclosure, no issue with extruding 9085 PEI, but I have not tested an actual PEI print (the volume above the build plate stabilizing at 50°C without being fully enclosed, which is pretty neat, but not enough for PEI)

- Is capable of dual extrusion - accomplished

- Is capable of fast travel speeds with reasonable accelerations - accomplished

Many thanks to Slice Engineering, PrintedSolid, and Filastruder ( @elmoret ) for fast shipping, excellent communication, and great customer service when it was needed, as well as to the Duet team for a fantastic product.

)

)

)

) GT

GT

]

]

Stratasys gets a bad rap - and I do believe from the 'maker' community much of it is justified - but the user experience for most of their customers is second to none. Can a machine like that print a benchy? Debatable, but if I need a 750g chunk of ABS printed up, the stability and ease of printing with that Stratasys printer is my benchmark.

Stratasys gets a bad rap - and I do believe from the 'maker' community much of it is justified - but the user experience for most of their customers is second to none. Can a machine like that print a benchy? Debatable, but if I need a 750g chunk of ABS printed up, the stability and ease of printing with that Stratasys printer is my benchmark.

I don't see enough in that thread for me to identify any concrete 'gotchas' but to me that probe point one is a big one. Unsure if those config and bed.g lines are mirrored in their RRF2 config.g.

I don't see enough in that thread for me to identify any concrete 'gotchas' but to me that probe point one is a big one. Unsure if those config and bed.g lines are mirrored in their RRF2 config.g.