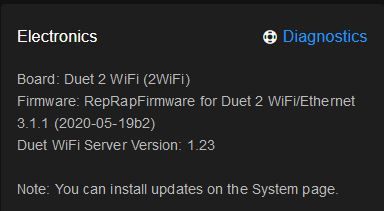

The extra 4GB SD card in the Panel Due display worked with out trouble in RRF2.05 on my Duet Wifi.

After upgrading to 3.1.1 from 2.05 it now fails.

I tried reformatting the SD card as per the suggested SD fomat tool and the SD card is formatted as FAT (16) for 4gb and smaller as suggested in documention.

I can mount SD 1

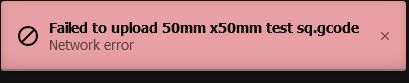

I have been able to upload one small file a 50 x 50 test square 98.5k file

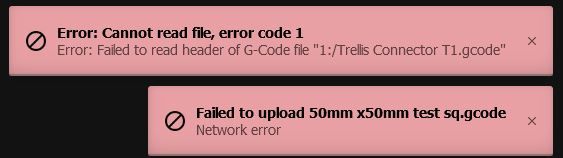

Can not load any other files via "Upload G-code files" , get "failed to upload network error"

If I try to print the one file on SD1 I get "M32 "1:50mm x50mm test sq.gcode" not found

If I remove the SD card and put it back again with changed files and hit refresh it shows no jobs ,

also it complains that it

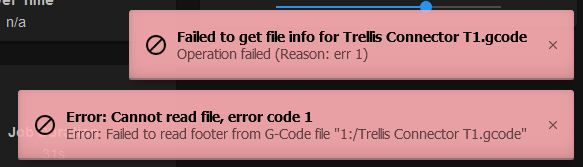

cannot get file info "operation failed (reason: err 1)

Error:Cannot read file, error code 1

Error: Failed to read footer from g-code file

If I reboot printer and remount SD1 it shows the file names successfully , but with a "response too long see console"

Error: Cannot read file, error code 1

Error: Failed to read header of G-Code file "1:/50mm x 50mm test sq.gcode"

Error: Cannot read file, error code 1

Error: Failed to read header of G-Code file "1:/Trellis Connector T.gcode"

I can upload files with out trouble to SD 0 ,the on board micro SD and print those successfully .

m122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.1.1 running on Duet WiFi 1.02 or later

Board ID: 08DGM-956GU-DJMSN-6J1DD-3SJ6K-1ANHF

Used output buffers: 3 of 24 (13 max)

=== RTOS ===

Static ram: 27980

Dynamic ram: 92952 of which 44 recycled

Exception stack ram used: 304

Never used ram: 9792

Tasks: NETWORK(ready,284) HEAT(blocked,1224) MAIN(running,1880) IDLE(ready,80)

Owned mutexes:

=== Platform ===

Last reset 00:06:15 ago, cause: power up

Last software reset at 2020-09-21 01:44, reason: User, spinning module GCodes, available RAM 9544 bytes (slot 3)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task MAIN

Error status: 0

MCU temperature: min 33.1, current 35.6, max 36.8

Supply voltage: min 24.4, current 24.6, max 24.8, under voltage events: 0, over voltage events: 0, power good: yes

Driver 0: standstill, SG min/max not available

Driver 1: standstill, SG min/max not available

Driver 2: standstill, SG min/max not available

Driver 3: standstill, SG min/max not available

Driver 4: standstill, SG min/max not available

Date/time: 2020-09-21 15:47:38

Cache data hit count 648880227

Slowest loop: 899.60ms; fastest: 0.12ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 4.5ms, write time 0.0ms, max retries 0

=== Move ===

Hiccups: 0(0), FreeDm: 169, MinFreeDm: 169, MaxWait: 0ms

Bed compensation in use: none, comp offset 0.000

=== MainDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== AuxDDARing ===

Scheduled moves: 0, completed moves: 0, StepErrors: 0, LaErrors: 0, Underruns: 0, 0 CDDA state: -1

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1 -1 -1

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 716.79ms; fastest: 0.00ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.23

WiFi MAC address 60:01:94:73:58:8f

WiFi Vcc 3.31, reset reason Unknown

WiFi flash size 4194304, free heap 20160

WiFi IP address 10.1.1.222

WiFi signal strength -64dBm, reconnections 0, sleep mode modem

Socket states: 0 0 0 0 0 0 0 0

#############################################

#############################################

; Configuration file for Duet WiFi (firmware version 3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.1.4 on Sat Sep 19 2020 10:37:56 GMT+1000 (Australian Eastern Standard Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Trium Duet3D 3V1.1" ; set printer name

;Diagonals 288.160:288.170:288.160, delta radius 145.243, homed height 407.792, bed radius 105.0, X -0.032°, Y 0.027°, Z 0.000°

M665 R145.300 L288.16:288.17:288.16 H408.00 B105.00 X-0.030 Y0.030 Z0.000 ; Set delta radius, diagonal rod length, printable radius and homed height

;Endstop adjustments X-0.07 Y0.17 Z-0.10, tilt X0.00% Y0.00%

M666 X-0.07 Y0.17 Z-0.10 X0 Y0 ; put your endstop adjustments here, or let auto calibration find them

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X160.00 Y160.00 Z160.00 E439.75 ; set steps per mm

M566 X1080.00 Y1080.00 Z1080.00 E3600.00 ; set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z12000.00 E1200.00 ; set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z1500.00 E2000.00 ; set accelerations (mm/s^2)

M906 X1600 Y1600 Z1600 E1250 I50 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 Z0.0125 S1 ; set minimum Z

; Endstops

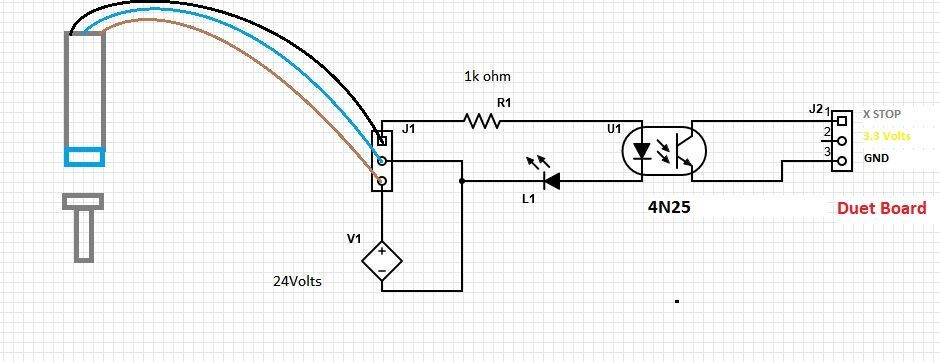

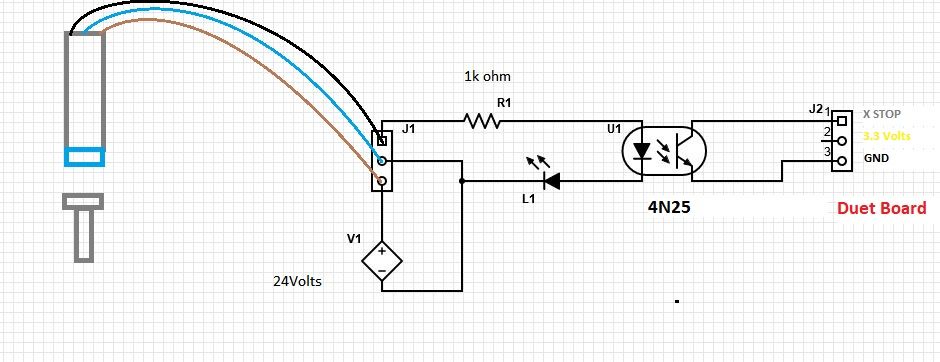

M574 X2 S1 P"!xstop" ; configure active low endstop for high end on X via pin xstop !prefix

M574 Y2 S1 P"!ystop" ; configure active low endstop for high end on Y via pin ystop

M574 Z2 S1 P"!zstop" ; configure active low endstop for high end on Z via pin zstop

; Z-Probe

M558 P5 C"e0stop" H2.5 F120 T4000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X0 Y0 Z28.48 ; set Z probe trigger value, offset and trigger height

M557 R100 P6:6 ; define mesh grid

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B0 A110 C422.4 D1.1 S1.0 V24.6 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B3950 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 A451.0, C96.0, D4.7 S1 V24.5 ; disable bang-bang mode for heater and set PWM limit

; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F1 C"fan1" ; create fan 1 on pin fan1 and set its frequency

M106 P1 S1 H1 T60 ; set heat break fan1 value. Thermostatic control is turned on

; Tools

M563 P0 S"EXT 1" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

; Custom settings are not defined

; Miscellaneous

M575 P1 S1 B57600 ; enable support for PanelDue

;M501 ; load saved parameters from non-volatile memory