EDIT: I1 and pullup removed from code

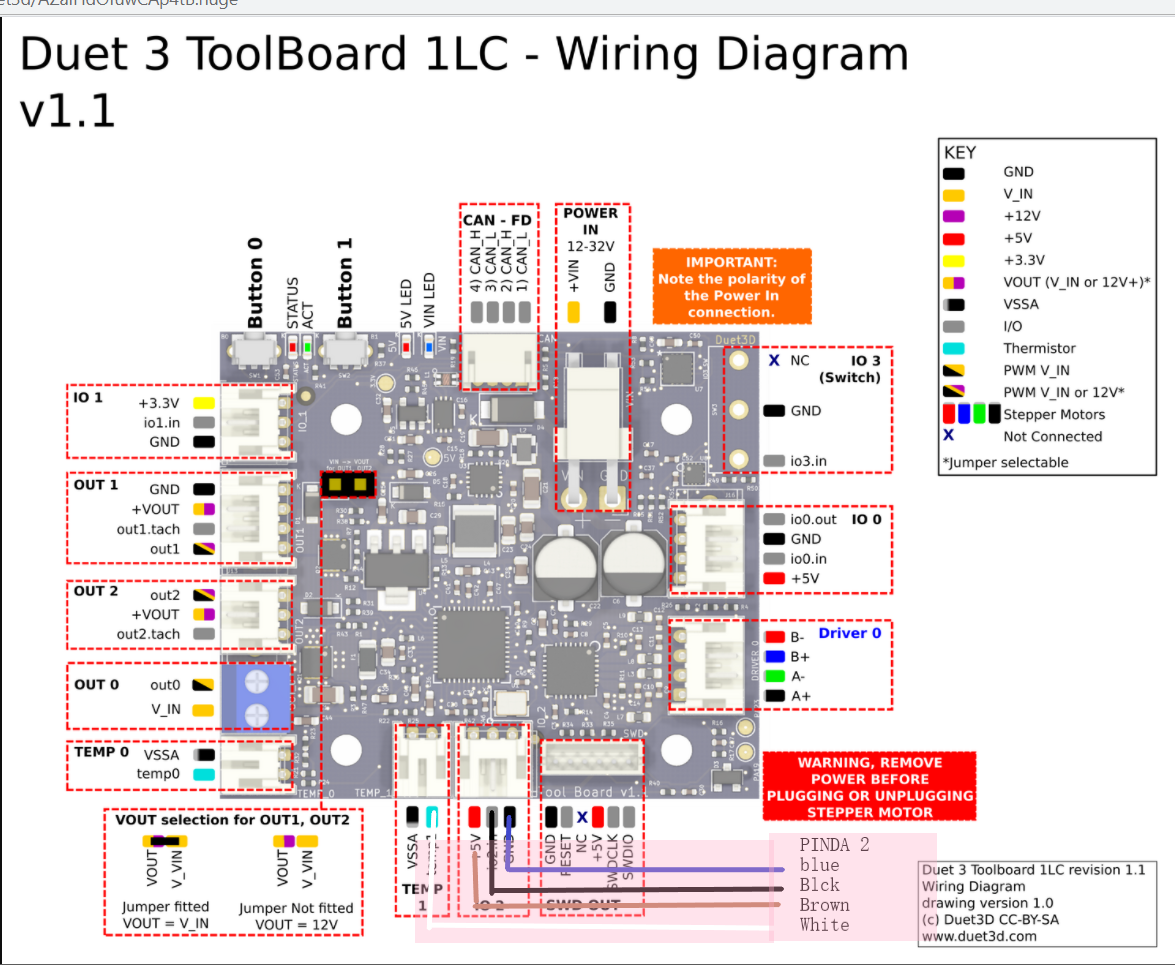

I spent an hour or so reading the different posts to find how to wire and set Pinda2 probe on the tool board v1.1 of my new CoreXY machine. So here is some info for others to use. This will work for other inductive sensors, just do not connect temp1 connector

Wiring

Configuration

; Z-Probe

M671 X-31.39:250:531.36 Y18:433.3:18 S10 ; Locations left, center, right

M558 P8 C"121.io2.in" H0.7 F1000 T6000 A20 S0.005 ; PINDA set Z probe type to switch and the dive height + speeds

M308 S2 P"121.temp1" A"PINDA" Y"thermistor" T100000 B3950

G31 P500 X-3.20 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X20:485 Y41:360 P7 ; define mesh grid

Here is the probe repeatability test result

6/6/2021, 9:26:30 AM G32 bed probe heights: -0.001 -0.003 -0.003 -0.002 -0.002 -0.003 -0.002 -0.003 -0.002 -0.003 -0.001 -0.003 -0.003 -0.003 -0.002 -0.002 -0.001 -0.001 -0.002 -0.001 -0.000 -0.001 -0.002 -0.002 -0.002, mean -0.002, deviation from mean 0.001