@o_lampe if you just want to know whether the filament is loaded, you can try using stall detection on the extruder for that.

Posts made by oliof

-

RE: Use IR probe as filament switch?posted in IR Height Sensor

-

RE: Use IR probe as filament switch?posted in IR Height Sensor

@o_lampe rq3 also developed an LED driven filament sensor that allegedly (I never used it myself) works better than the usual IR approach especially with filaments like PETG which are invisible to IR.

-

RE: KINEMATIC ?posted in General Discussion

@rkutun See https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m669-set-kinematics-type-and-kinematics-parameters

As @dc42 writes in https://forum.duet3d.com/post/296209 you will need to specify Cartesian or Mark Forged kinematics using the K parameter, then modify the matrix using the X Y Z and U parameters. You can also reference the MULDEX config at https://github.com/3dprintingworld/MULDEX/blob/master/Firmware/sys/config.g

-

RE: I think I would like a variation on M208posted in Firmware wishlist

@T3P3Tony I would adjust the M208 limits in the tool change macros but I can see how that's fraught to errors if a tool change fails or tool change with

P0is required. -

RE: I think I would like a variation on M208posted in Firmware wishlist

@fcwilt if you set the tool offsets with G10, they should apply towards the reference head point, which is Tool 0, to which M208 applies. Is that not sufficient in your case?

-

RE: Select a default tool in a toolchanger arrangementposted in Gcode meta commands

You could add

T0 P0at the end of config.g to have a default tool selected, or in start.g which is executed before the gcode file (P0 to avoid running the pre and post macros, so leave out if you want to but at the end of config.g without being homed it'll likely throw an error). -

RE: My new simplified printer designposted in My Duet controlled machine

@T3P3Tony that needs just a couple of led lit cable guides (-:

-

RE: My new simplified printer designposted in My Duet controlled machine

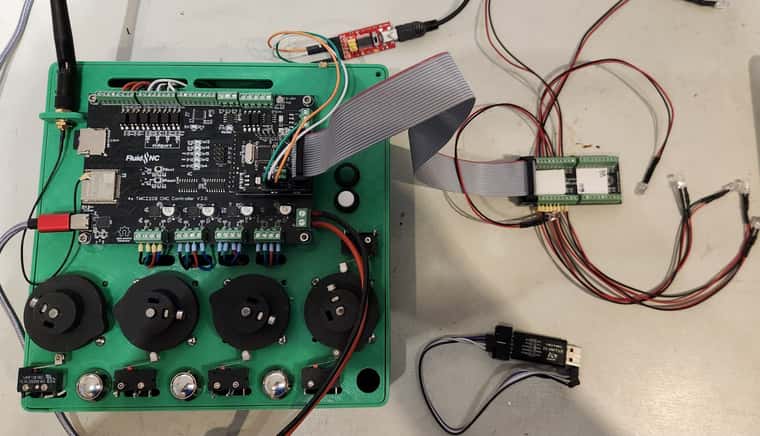

@droftarts maybe do something like the test rig one of the FluidNC devs came up with

-

RE: Duet 2/Duex5 looking for a good homeposted in 3D Printing General Chat

@elmoret those used Duet2s seem to be a gateway unto RRF for a bunch of people with tight budget that get fed up with barrel scraper boards failing on them. Its a great service you provide.

-

RE: [FW 3.5.2] High jerk good for circular path not for cornersposted in Tuning and tweaking

@Triet the smoothing is a side effect of effective input shaping.

-

RE: Need help with 5 Bar SCARA configurationposted in Firmware installation

@JoergS5 for standard scara I seem to remember that H2/ direct motor moves happen in degrees (because if you command a single motor directly you can't command any position as with cartesian). Is that true for 5bar scara as well?

-

RE: How many tools?posted in General Discussion

@Aurimas IMO USB connectors are a terrible choice because someone will plug the wrong wires with rhe right connector in and then things will go splooey.

Also USB connections arent specced for motion, so having them on a toolboard invites them getting loose over time.

-

RE: 3.6.b3 mainboards as expansion boards disconnect during printingposted in Beta Firmware

@aetherialdesign HeatTaskStuck sounds unusual, maybe @dc42 can help out

-

RE: How many tools?posted in General Discussion

minimum of four tools for tool changer just seems to be an evolutionary inevitability to me. For two tools, IDEX is much easier to build and use (and you can make tool changes in less than two seconds with careful tuning). For three toolheads, its just not worth the added complexity and cost of machine space so four is the viable minimum and six/seven the viable maximum without enlarging the machine just to get more docking area ...

(yes, you can get a PrusaXL with one or two tools, but thats a business consideration).

-

RE: [Bug / Feature Request]: negative temperatures in chartposted in Duet Web Control wishlist

@pixelpieper maybe check the BtnCmd plugin for a customized UI and temp chart

-

RE: Automated and 3D printed ski and snowboard Ptex/HDPE repairposted in General Discussion

@yoshimitsuspeed the IR probe does not work as a scanning probe but dc42 indicated it should be pissible to turn it into one with firmware modifications. Nobody has indicated that this work is planned though.

-

RE: IR Height Sensorposted in Duet Hardware and wiring

@br7408 it didnt endeavor the threat of replacemebt I guess.

-

RE: Motor problems on RatRig V-Core 3posted in General Discussion

@Electriceye to check drivers to work you cant just use a multimeter, you need to use an oscilloscope to see whether they properly generate steps. Alternately you can use a stepper driver analyzer (search the forum for more info), but in the end that's more or kess an oscilloscope with sone predefined settings.

Blown drivers usually exhibit "craters" or little blow holes, so inspecting them visually is another option. Posting high resolution, focussed photos of drivers here allows us to help determine whether a driver is blown or not.

If a driver looks good, the next most likely culprits are still motor wiring/crimps (testable with a pull test holding the housing and tugging on the wires and solder defects for the pins (also visually detectable).

Regarding the Octopus board: The heatsinks on the plastic housing act much less as a proper heat dissipator than the vias designed into duet boards and the high copper content on the duet board.

The duet boards are best cooled by blowing a bit of air above and below the board along the drivers.Another drawback of the stepstick format is the inherent current limitation and the usual arrangement making proper cooling on top and bottom of the stepsticks difficult, especially with banks of jumpers blocking airflow.

-

RE: IR Height Sensorposted in Duet Hardware and wiring

@br7408 it may be a faulty probe, a similar case of this was handled under warranty (ref https://forum.duet3d.com/topic/30051/ir-probe-faulty-triggers-well-before-the-actual-trigger-point/22). One for @Phaedrux I guess.