@dc42

Thanks David!

The idea would be stay at max 100d in the enclosure. This should be enough for the material I'll go to print . But to have some margin can be useful , for safety and maybe upgrade. The link is very appreciate !

For peek I read that the enclosure should stay from 70 to 150d . I cannot effort the 150 target (because all the hardware limitation) but maybe a compromise is achievable and enough at the end.

I'm not in hurry to finish the printer so I would like build something that have sense and is coherent with all its parts.

I'll keep you informed on the progression of the selection and installation !

Cheer !!!

Posts made by giostark

-

RE: End Stop for high temperature coreXY - suggestion/adviseposted in Duet Hardware and wiring

-

End Stop for high temperature coreXY - suggestion/adviseposted in Duet Hardware and wiring

Hellooooooo ! Dear beauty of a community

...

...

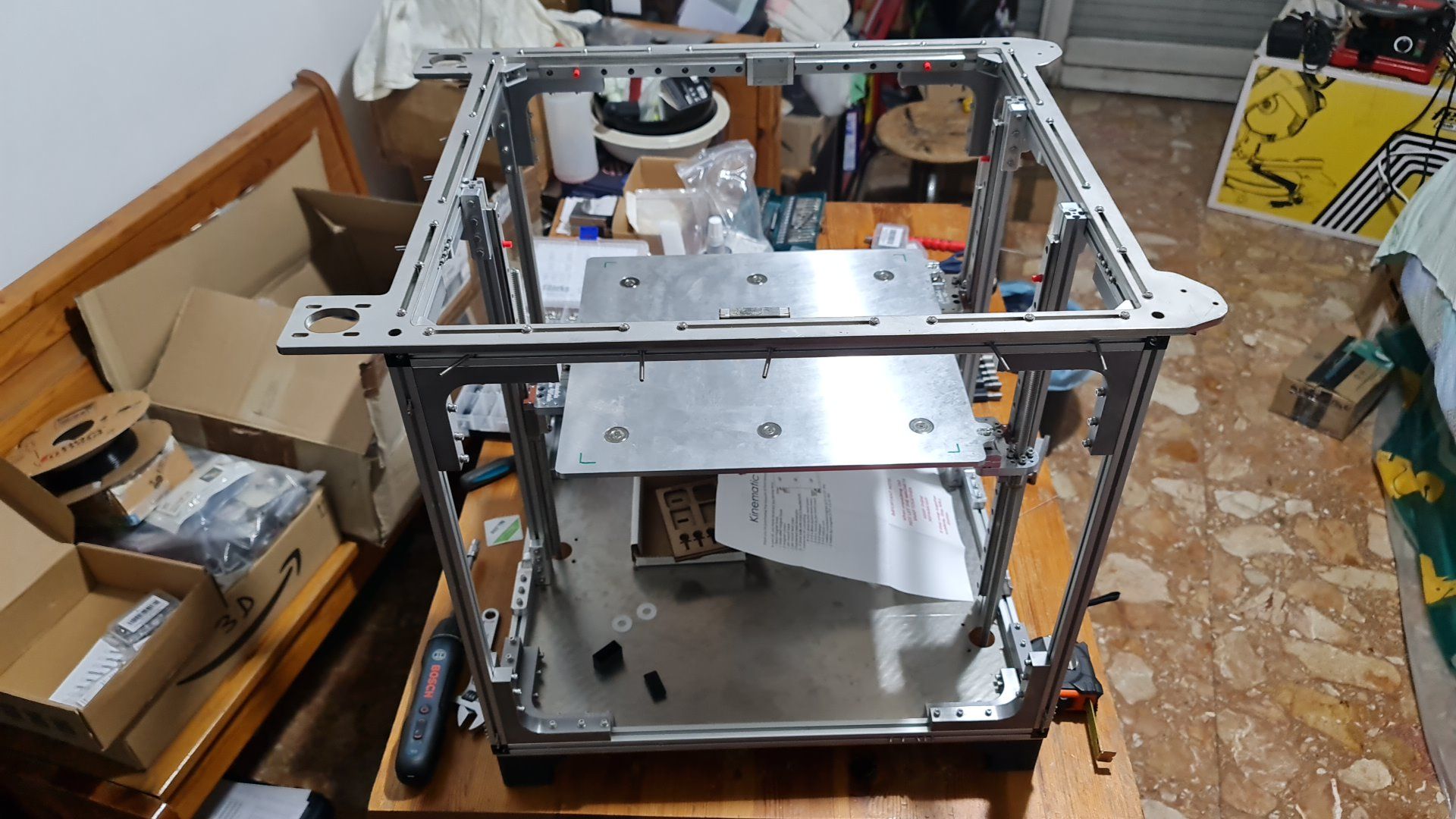

Im building (as reported lots of time ago) this "fine" piece of printer.

I'll open the proper 3D in the right section with all the spec , mods , developments etc etc.

The electronic are all Duet . With some structural customization , but the project is this one https://railcore.dozuki.com/c/RailCore_II

Now:

This thing would be designed for high temp material . The rails are Misumi for high temp (rated 140deg) . Rest is metal.

The problem I realized , the end stop ! Rest intended that I have to build their support but , which ones ?

The ones I found may resist and stay operational till 85 degree . But If I'll print policarbonate or peek this will be not enough (maybe) or too close the rated temp.

Do you have any suggestion on the right model suited for the task ? And maybe also where to buy them.

I'll need 7 of them. 2 for X , 2 for Y and 3 for Z .

Thanksss ! -

RE: use M552 to abandon the current connectionposted in General Discussion

@droftarts

Thanks Ian !

I wrote to Phaedrux and asked him to do this . (I wrongly supposed him would ask you that because instead you were faster !)

This community is very great . I really really like it , so I hope to be helpful in future.

Cheers ! -

RE: use M552 to abandon the current connectionposted in General Discussion

@jay_s_uk

Eh...you nailed it Thanks.

Thanks.

I don't understand why my brain did not considered this option. Damn.

Anyway would be useful for other noob to add this line in the guide right under the " Use M587 to add a WiFi..." :"If you have already store the connection , disable the line M587 with the wifi data." (or something like that)

This is the standard setup, with the Duet 3 Mini 5+ WiFi (in standalone mode) or Duet 2 WiFi connecting to your network through a WiFi access point/router. This is covered in the Getting Connected guide. Briefly: Connect to Duet, via USB and serial terminal, or via console if already connected to network. Use M587 to add a WiFi host network to the remembered list of networks. To set a static IP address, use the 'I' parameter in your M587 command. If you leave this out, the Duet IP address will be set by the router, using DHCP. Use M552 S1 to turn on networking, and connect. You can specify the host network to connect to using the 'P' parameter, so long as the host network has already been stored using M587. Note: the IP addresses in the following diagram are an example of how a network may be configured. Your network may use different IP addresses and ranges. -

use M552 to abandon the current connectionposted in General Discussion

Hi ALL !!!

Finally back in business

Probably after an update is popped out this error:Error in start-up file macro line 29: use M552 to abandon the current connection attempt before using this commandMy network section was always like this with no errors:

; Network M550 PDelta-Printer ; Set machine name M552 S1 ;G4 P1000 (old setting to create a delay from activation wifi and check the wifi name saved previously) M587 S"*****" P"*****" I***** M586 P0 S1 ; Enable HTTP/HTTPs M586 P1 S0 ; Disable FTP M586 P2 S0 ; Disable TelnetI tried to enable or disable the G4 P1000 but do not change a thing.

I would say that the error rise two update ago.config.g

I had a look here : https://docs.duet3d.com/User_manual/Machine_configuration/Networking

And seems fine the configuration.

Any clue ? -

(solved) Flickering LEDs and then dimposted in Smart effector for delta printers

Hi all ,

i know maybe I should not open this 3d , but to me this was enough singular so I have to report the success of the finding...

The smart effector the last year at one point it started to flicker/dimming . To me was strange some wiring malfunction just because I tried and checked so many time that all was correctly connected ... Frustrated at one point I give up. Then ... a sparkle... Do you want see that the Super Lube (grease) suggested to be used with the magnetic rods have inside some mineral that make it conductive? Nailed. I used some alcohol with cotton fioc to clean between the rods on the smart effector and magically it start to work as expected.

To me this was happened because the hot chamber raised the lube temperatures making it melt a little. -

RE: Flickering LEDs and then dimposted in Smart effector for delta printers

@Phaedrux said in Flickering LEDs and then dim:

@RogerPodacter May be best to start a new thread.

Hi folks ! I'm back on a CNC for make some part for a new 3D printer... so now i'm a little for other stuffs.

Today I start a print and this happen to me exactly in the same way.

I should open a new 3D but the things are exactly the same.

Tomorrow I'll check the connections and the suggested solution by David and report something. -

RE: Strange Blobbing on Layer Changeposted in Tuning and tweaking

@davidewen

On the Bondtech BMG I have settled E1200. Tie well the screw otherwise the gears will dent the wire. -

RE: Strange Blobbing on Layer Changeposted in Tuning and tweaking

@davidewen

Yep the Z in M566 could be higher. Right now I have just a delta printer and settled 800 on all 3 axis.

You have 900 on x and y. Why so slow on z with just 60?

David suggest the default as 600 in this post:

https://forum.duet3d.com/topic/310/m566-what-s-a-good-number

But someone use even 1200.Please if you found the solution replay here so that will be useful to us all

ps:

I have to learn to check before the config.g and then the slicer , damn. Here the phaedrux's skill was evident!

My advice still remain good for refinement

-

RE: Z seam blobs, pause at layer changeposted in Tuning and tweaking

@Phaedrux

Yo Phaedrux!

He posted the same thing here (link) and I tried to answer him... let see if he will solve the problem:

https://forum.duet3d.com/topic/14846/strange-blobbing-on-layer-change/32ps:

i'm restoring a CNC for build some part for the full metal CoreXY high temp I'm assembling... That will be a very fine piece of hardware

Soon as possible I'll post stuffs

-

RE: Strange Blobbing on Layer Changeposted in Tuning and tweaking

@davidewen

Hi Davide,

Maybe you are super skilled already with all those programs , I'll just try to be cooperative.

Is a little hard to tell for sure regarding just one possible solution.

I use Cura and I can try suggesting something using it.- Try to use Cura 4.13.1. The 5.X series address some issue with concentric shapes (the width of the lines) and is removed the function of exclude tiny gaps, resulting in additional movement and extrusions. (maybe is not the case but on circular shapes could help the first point).

- Try to use defined seam. (so , not the shortest nor the random or sharpest) . In the preview look for the best position where to place the seam. (back , front, left etc) . Try to obtain on vertical line as seam. If necessary rotate the shape. (Cura is rotation sensitive , and you can discover it looking the support lines)

- Try to work on Wall > outer wall wipe distance. (should help to hide the seam inside the shape)

- Try to work on Travel > disable retraction at layer change (this avoid pause and leak of materials because the pressure)

- Try to work on Travel > combing mode on all (less retraction > less pressure changing > less leaking)

- Try to work on Travel > disable retraction before outer wall

- Try to work on Experimental > enable coasting . Here work on the number of the area of the nozzle. (moving without retraction should reduce the amount of material leaked for the variation of pressure. If you exaggerate with this option , or the sum of all those settings, you could generate holes instead of blobs).

- Keep in mind that if you change layer height , all those parameters will change. To my printer ,to print at 0.3 or 0.2 is not absolutely the same.

And you have seen by yourself with the first shape on left that emphasize the issues. - Keep in mind that not all the shape can use the same profile.

- The concept is to try to avoid the numbers of retractions and keep the material's extrusion the more constant you can.

- Then... is not exactly clear from the picture , because there are not 90 degree corners , check the belt tension. On quick and fast direction's change you can have a little of vibration of the nozzle. Or instead do not exaggerate with the speed of the print.

I tried to inspect your picture , thanks for the high resolution.

The lines seems good except for the seams.

I'm optimistic that you can nail the right combo of settings. -

RE: Tevo Little Monster scratches printposted in Tuning and tweaking

@manuel

Hi ,

At this page you can find the delta printer calibration full explanation:

https://duet3d.dozuki.com/Wiki/Calibrating_a_delta_printerIf you are sure about the numbers that you added (thickness of the glass) you can just modify the "System > config-override.g" file in the M665 line at the H parameter (subtracting the mm you added).

If this will go fine you can change the H parameter also in the config.gIn general for see the height of the printer:

1- power on the printer

2- home the printer

3- lower the head till the glass

4- when you are at the zero send in console G92 Z0 (to define the new zero level)

5- home the printer and read the new height value in the duet dashboard (Status > Z position) after the endstop are triggered. Keep in mind that the home position is lowered of 5mm (you can find your value in the homedelta.g , so you have to add also those mm to the height value you read in the Status > Z position.

6- write this new height in the config-override.g (and config.g)If you dont have changed also the nozzle height modifying the head of the printer , should be enough adjust the height as above.

-

RE: Where is Phaedrux?posted in Off Topic

@phaedrux

Geeeeeez I can understand why you are happy . The miracle of life now have a gaze curious

. The miracle of life now have a gaze curious  So many fresh neurons at work!

So many fresh neurons at work!

Poor little girl , now the father will automate the feeding bottle and change diapers !!! See... what 3d printing produce...

-

RE: "G28 Error: G0/G1: insufficient axes homed" after months of useposted in General Discussion

@ignacmc

Hi,

If you didn't touch anything (and before was working) it sound as the endstop are not read correctly.

Try to clean all of them. Look if the red light are operational.

Have you checked all the endstop? Try a singular independent move to see if all of them work regularly:

Testing the motors and endstops individually

https://duet3d.dozuki.com/Wiki/ConfiguringRepRapFirmwareDeltaPrinter#Section_Testing_the_motors_and_endstops_individuallyNot related now because you receive the error soon as you try to move, but it could be useful in future: When the head was placed on the extreme part of the bed and try to home is also happened that in the home.g this line had the X Y Z parameters too small and received your same error:

; Move all towers to the high end stopping at the endstops (first pass)

G1 X640 Y640 Z640 F2500 H1I'm at shortage of other ideas... hope some more expert can provide more suggestions

-

RE: Smart Effector setup issuesposted in Smart effector for delta printers

@incidrthreat

Hi, I have a delta so I'll try to be useful...

The error that is blocking your right probing is this , in "config.g":

Rnnn : Radius to probeM557 R90 S20 ; define mesh gridThe R parameter MUST be bigger that the value (radius) you set in http://www.escher3d.com/pages/wizards/wizardbed.php bed generator.

Now , as you wrote , they are coincident so they come skipped.

Your radius is 140 so try M557 R120 S20 instead.Then, cosmetic stuff... I suggest you to erase the G31 line in the config-override and work for the zprobe in config.g for don't make splitted code. And leave geometrical and other auto-calibration in the override.

1)In config-override (remove this line and work in config.g):

; Z probe parameters G31 K0 P500 X0.0 Y0.0 Z-0.31-What is in G1 "K0" for? in the wiky https://www.reprap.org/wiki/G-code#G31:Set_or_Report_Current_Probe_status it is not mentioned.

I dont know if this can generate errors somewhere. Remove it.

-Try to set "Z-0.1" till you are not certain that all work as it should. Then you'll refine the stuffs.

-P500 . For the smart-effector this line is suggested G31 P100 X0 Y0 Z-0.1. (look at commissioning)

https://duet3d.dozuki.com/Wiki/Smart_effector_and_carriage_adapters_for_delta_printer

https://forum.duet3d.com/topic/16758/g31-trigger-value-what-is-it-good-for?=16413455686242)In config.g ,despite it come bypassed by the config-override.g ,change the Z from 5 to Z-0.1. 5 mean to fly too hight for the head.

G31 P500 X0 Y0 Z5For the smart-effector this must be "P8" not "P5"...

M558 P5 R0.4 C"zprobe.in+zprobe.mod"For the axis limit set a negative value so that if your Z0 is too high (for some reason) and with babystep you have to go really close the bed , you'll can. Set it ex at Z-0.3.

; Axis Limits M208 Z0 S1 ; set minimum ZAfter you made those change to the code:

-power off , power on the printer.

-home (G28)

-run a single probe (G30). (it will be slow)

-keep the right height and write it in the override.g M666 H parameter.

-restart the printer

-run at least 3xG32

-in console type M665 for read the actual value and copy ONLY the R in the ovverride.g. (and leave the M666 to 0 for all the items)

In this way you will leave to the auto-calibration the job to recalculate the other parameters. In my experience if you put too much manual settings and they are not perfect , the result come even worse.

So basically for the M665 you can add manually : rod length , radius (after at least 3 calibration) , height.It's late here in Italy... I dont' know if there are more errors in your files... but I'll collapse .... try those change and let us know

-

RE: Does anyone here work on Superslicer?posted in General Discussion

OT/ team at work , such a nice reading

/OT

/OT -

RE: Smart Effector slipping.posted in Smart effector for delta printers

@gaou

And also check the wires , just in case. Can happen that if the movement of the head modify the tension of the cables , in some area of the bed the contacts could be not perfect.

Plus, if is it possible don't calibrate with everything too hot (bed and nozzle) , can occur inconsistency trigger read . -

RE: (EDIT) Haydn Huntley 1cm magnetic bars not for enclosure (60°).posted in My Duet controlled machine

@giostark

Hi all !

After the first enthusiasm I managed to make my printer work a little sustained and the limit of some materials come up.

Unfortunately the only thing that make those bars not valid for be used in an enclosed environment is the Delrin. This is a good material for lots of application , it versatility lies in the good resistance at friction and the possibility to be cnc milled very good. BUT with the heat the game change.

With Haydn make we made this experiment and unfortunately it didn't succeeded.

After long print in an enclosed system with a temp of 60 Celsius (i meant 20+ hours at print) , despite using the proper lubricant changed at each print (super-lube), the Delrin start to consume making the magnet inside the bar come to touch the metal ball , finally scratching it.

I have several other ball sets so now the evolution of this project is substitute the Delrin with some metal ones. I have to ask to friends with good lathe.

I'll let you know how to the stuffs will go...

-

RE: Where is Phaedrux?posted in Off Topic

@phaedrux

Buya Phaedrux!! WOW ... simple stuff no eh?! Otherwise life would be boring

Me too I'm very glad the things are going fine ... second child?... so scaring

... second child?... so scaring  there you must be a hero !

there you must be a hero !

Ligament or meniscus ? Me too I'll have to be drilled. One month ago a car decided to change line without looking, in the highway... Of course I was in motorbike (GSXR1000) at the according speed of the instrument .

By the way , still here we are !